Honway Industrial | Your exclusive polishing partner for your process

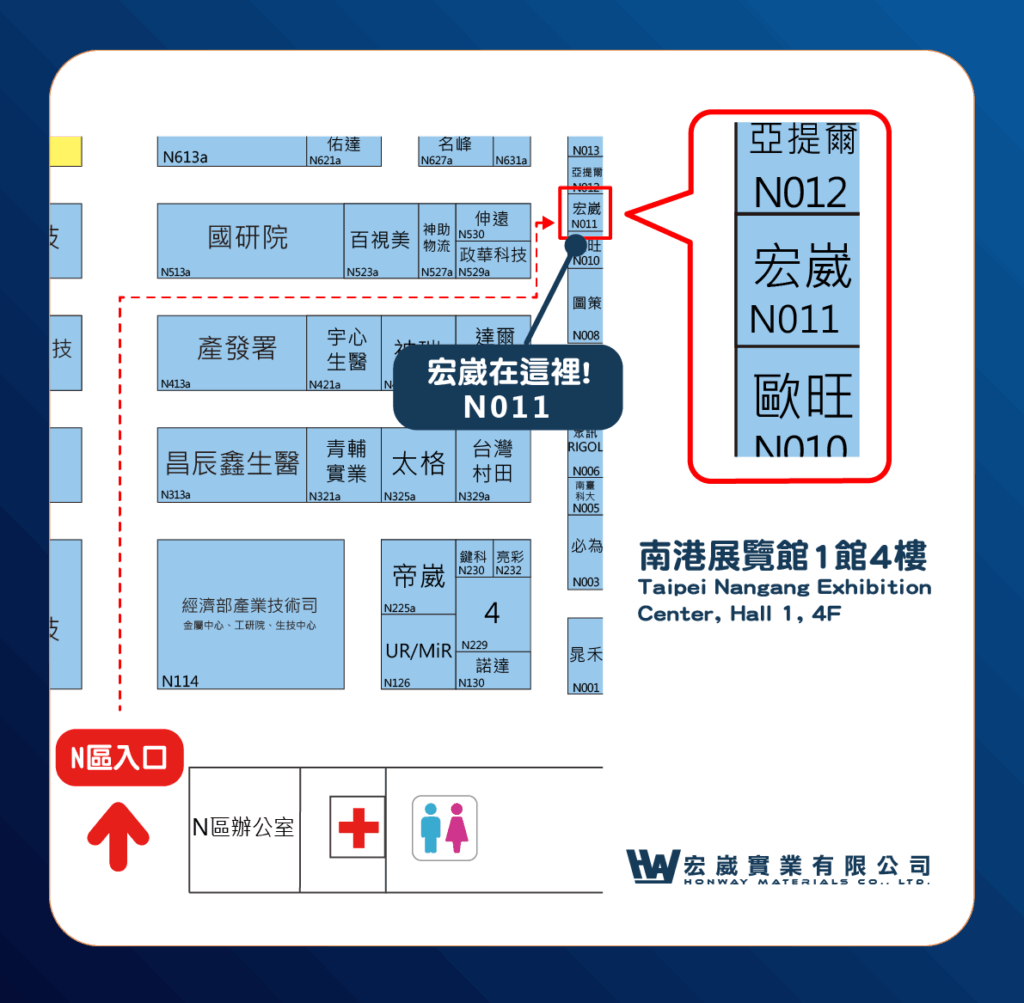

- Exhibition Information:

- Dates: December 4th (Thu) – December 7th (Sun), 2025

- Location: 4th Floor, Hall 1, Taipei Nangang Exhibition Center

- Booth Number: N011

“The driving force behind precision medical devices: suppliers of high-quality ultra-hard consumables and rare earth raw materials”

HonWay Materials co,ltd is deeply engaged in the field of grinding and polishing consumables and rare earth raw materials. With many years of professional experience, competitive prices, stable rare earth supply chain and excellent customization capabilities,

We can be your solid support to improve process efficiency and optimize product yield. We not only provide high-quality materials, but also strive to create exclusive solutions and technical support for you.

Highlights of Hongwei Industrial Exhibition

Precision deburring × efficient surface treatment

After machining metal workpieces, burrs often form that are difficult to completely remove, affecting assembly precision and shortening the life of the part. Traditional grinding methods are inefficient, time-consuming, and labor-intensive, increasing costs. Furthermore, the surface treatment is uneven, resulting in inconsistent quality. The Hongwei Diamond Brush Machine, equipped with its exclusive diamond brush wheel, thoroughly removes burrs, ensuring smooth, even surfaces.

Advantages of diamond brush machine:

- Diamond brush wire is highly wear-resistant: long life and high stability

- High-precision deburring: can be used for processing complex structures and small holes

- Improved efficiency: shortened processing time

- Good surface consistency: ensure smooth parts without residual burrs

- Applicable to multiple materials: steel, alloy, hard and brittle materials can be used

Ultra-finishing solutions: the key to achieving nano-level precision

In response to the stringent demands for polishing workpieces such as difficult-to-grind materials and super-hard metals, Honway provides grinding and polishing consumables and processing equipment designed specifically for them.

We are well aware of the manufacturing challenges these materials present. Through precise formulation and equipment design, we can help you reduce processing time, overcome surface defects, achieve the nano-level surface finish and flatness required for components, and comprehensively improve product performance and yield.

High-quality diamond grinding wheels & CBN grinding wheels | Precision machining solutions for difficult-to-grind materials

As a leading supplier of super-hard polishing materials, Hongwei ensures the provision of high-quality, stable and demand-oriented grinding wheels, grinding rods, dressing knives and other tools.

In today’s volatile global supply chain, our stable supply capacity is a reliable guarantee for your uninterrupted production and controllable product quality.

Advantages

- Extremely high hardness and wear resistance: suitable for long-term stable processing of superhard materials

- Precision surface quality: effectively reduce chipping and cracks, and achieve excellent roughness

- Improved processing efficiency: strong cutting force and shortened grinding time

- Long life and low cost: Reduce the frequency of grinding wheel replacement and reduce the overall consumables cost

- Stable dimensional accuracy: ensuring high quality consistency in batch processing

- Wide range of applications: high-precision optical lenses, implantable medical devices (such as bone screws and artificial joints), surgical instruments, and syringe needles (including the inner wall).

Customized grinding recipes and technical support: tailored to your challenges

Your process problems are the solutions provided by HonWay.

We are not only a supplier of consumables, but also your technical partner. HonWay has a team of polishing engineers with rich industry experience who can deeply understand your specific needs and pain points. Whether it is adjusting product formulas, optimizing existing processes, or providing on-site technical support, we can tailor the best polishing solution for you to ensure your process is smooth and efficient.

Rare earth raw materials: the “core driving element” of high-end medical devices.

Our rare earth raw material supply focuses on providing high-purity, stable, and reliable basic materials for your precision medical applications, ensuring that end products meet the most stringent performance standards.

Do you have these problems? HonWay provides solutions!

Honway Solution: Our diamond abrasive tools can be designed with proportions adjusted according to needs, specifically for fine, controlled cutting, avoiding micro-cracks and edge chipping, and ensuring stable surface flatness and roughness.

Honway Solution: Our customized polishing formulas and professional technical support can accurately analyze and resolve surface defects caused by consumables, significantly improving product yield.

Honway’s solution: Through innovative grinding and polishing consumables and optimized process recommendations, we help you shorten polishing time, significantly improve production efficiency, and reduce single-wafer costs.

Honway’s solution: Acer offers competitive pricing while ensuring superior quality, giving you a better total cost of ownership (TCO).

Honway’s solution: Our company’s diamond grinding tools have extremely high hardness and wear resistance, which can greatly improve the cutting rate and processing efficiency, and shorten the processing time.

Technology Insights / Industry Views

Electron Beams Create Next-Generation Nanodiamonds: University of Tokyo Breakthrough in Room-Temperature Synthesis

Soaring Prices of Rare Earth Element “Yttrium”: A New Focal Point for Global Supply Chains

Unlocking the Secret Order of Metals: MIT Discovers “Atoms Don’t Completely Randomize” in New Material Law

【Supply Chain Response】 Industrial Diamond Solutions Under China’s Controls: Honway Helps You Master SiC/GaN Wafer, High-Power Component Polishing, and Heat Dissipation Substrate Spot Supply

Quantum Breakthrough on Silicon Chips: Nuclear “Call” Enables Scalable Quantum Computers

China Implements Export Controls on Synthetic Diamonds: Global Supply Chains and Taiwan Industry Face New Challenges

Demystifying CoWoS, CoPoS, and CoWoP: Unveiling the New Era of Advanced Packaging Technology

Contact Information and Map

Telephone | Tel: +886-7-2231058 |

Exhibition time | 12/04-06 10:00am-06:00pm 12/07 10:00am-04:00pm |