This thing feels so rough! How rough is it?

This thing feels so smooth! And what about its roughness?

In the pursuit of precision within industrial fields, such expressions are akin to saying, “The sea is blue.” Yet, the shade of blue in your mind may differ from mine. To address this variability and improve yield rates, the definition of surface roughness was established in the 1940s. After numerous revisions, it eventually became the industrial standard that we rely on today.

*Ra, Rz, and Rmax are often used in the industrial field, and this article will focus on “Introduction to Surface Roughness – Line Roughness”, so if you want to understand the differences between SA and RA, please refer to this section>>> for the differences between RA and SA

目錄

Measurement Terminology:

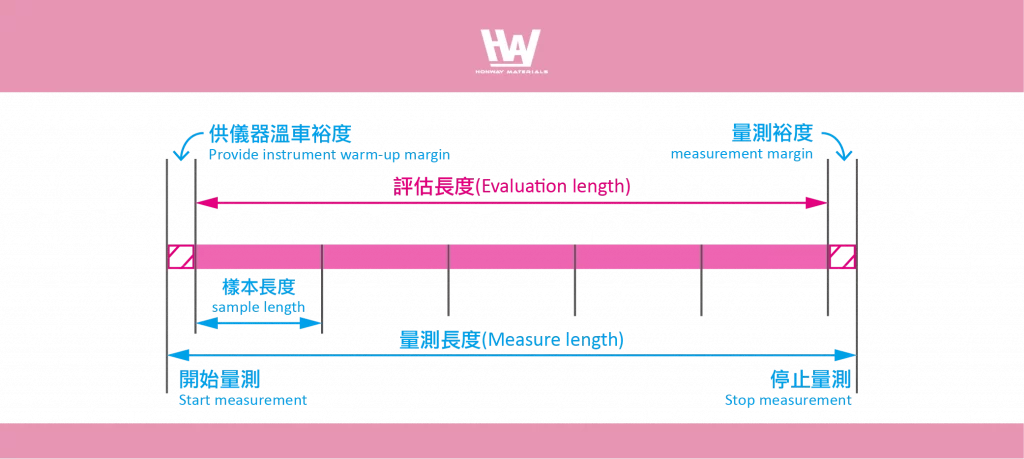

Before diving into the different representations, let’s first understand some of the key terminology that is commonly used across most of these representations.

- Irregularities: the peaks and troughs of the curve

- Sampling length: The surface length sufficient to represent the entire roughness pattern.

- Assessment Length: The length that includes several sampling lengths, where the measurement is the average value of several parameter evaluations.

- Traverse length: The entire length of the surface that is measured when using a probe.

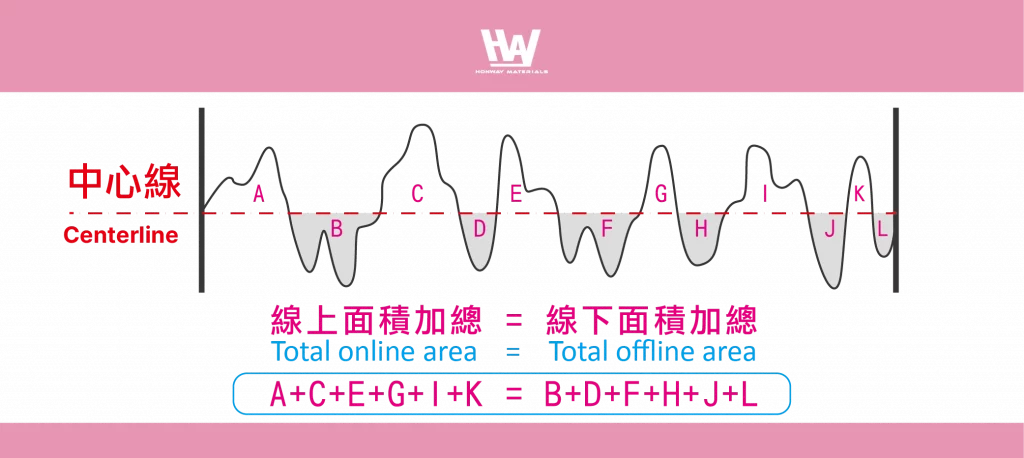

- Reference Line: A baseline used as a standard to quantify and evaluate the surface roughness profile.

- Center Line: A reference line that divides the surface profile into two equal areas and runs parallel to the general direction of the profile.

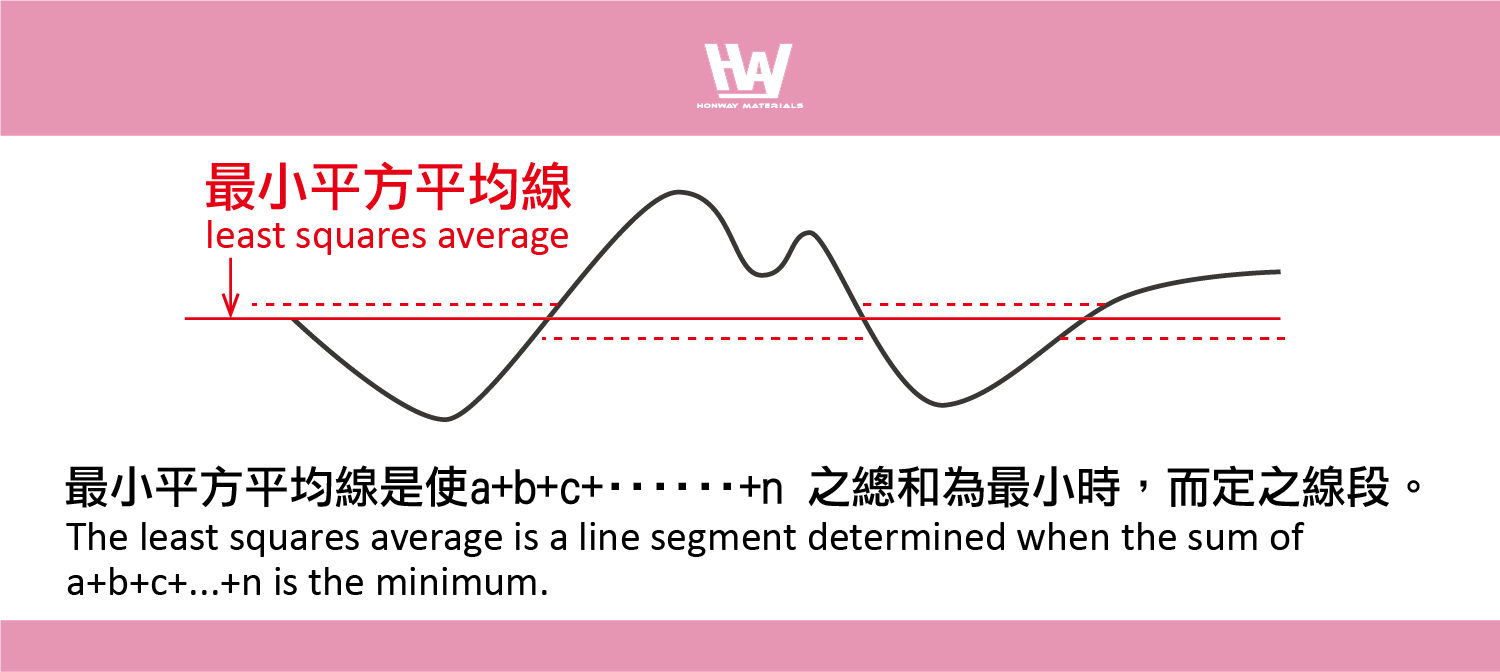

- Least Square Mean Line: This is a line derived from a section of the surface roughness profile. Within a specific interval of the profile, a straight line is established such that the sum of the squared deviations (distances) of the profile points above and below this line is minimized. This line is referred to as the “Least Square Mean Line.”

Common Representations of Surface Roughness

| Representations | Definitions | Illustrate | |

| 1 | Ra | The arithmetic mean deviation of the profile | The average of the absolute values of the distances from each point on the measured actual profile to the profile’s centerline within the sampling length L. |

| 2 | Rt [Rymax] | Maximum height of the roughness | The sum of the maximum peak to the maximum valley value within the sampling length , i.e., Rt = Rp + Rv. |

| 3 | Rz (JIS) [Rtm] | Ten-point mean height of micro-roughness. | This parameter, also known as the ISO ten-point height parameter, represents the average height between the five highest peaks and the five deepest valleys within the sampling length . |

The relationship between the above three roughness is 4 Ra ≒ Rymax ≒ Rtm

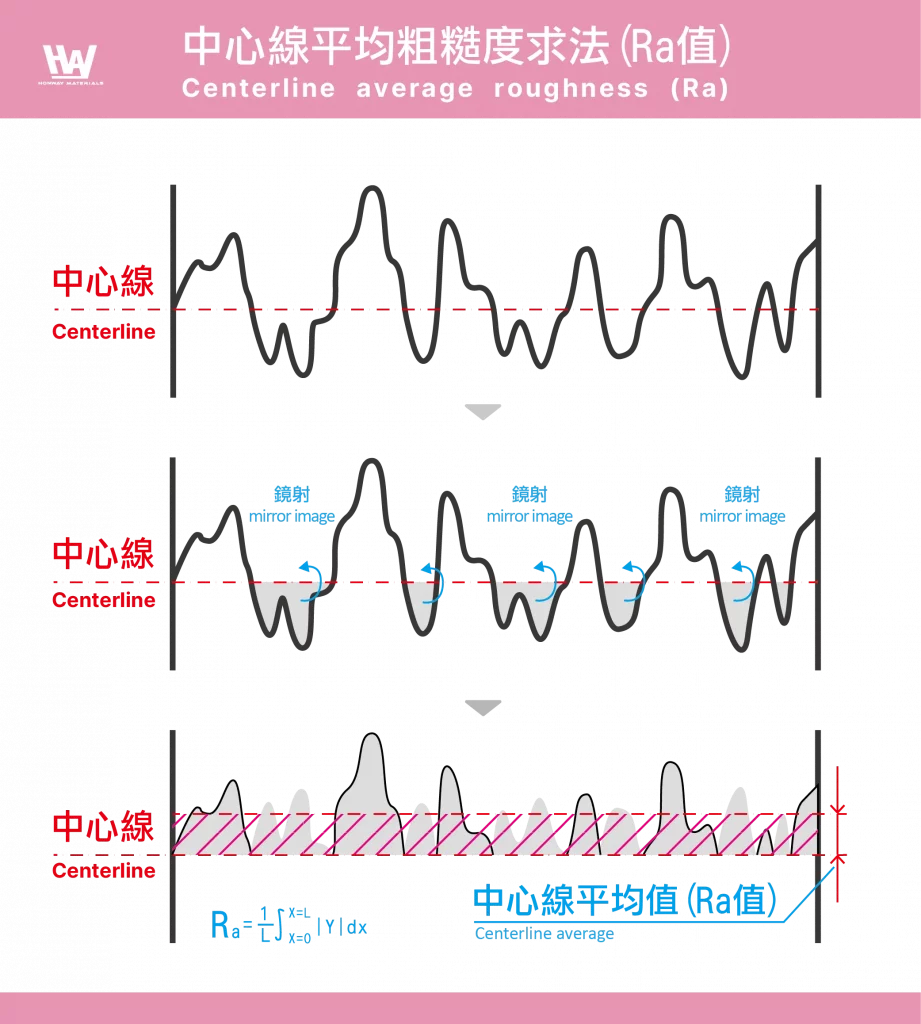

Center line average roughness (Ra)

The arithmetic mean of the shape deviation from the centerline over the entire length of the sample

Ra=(|Y1|+|Y2|+…..+|Yn|) /n

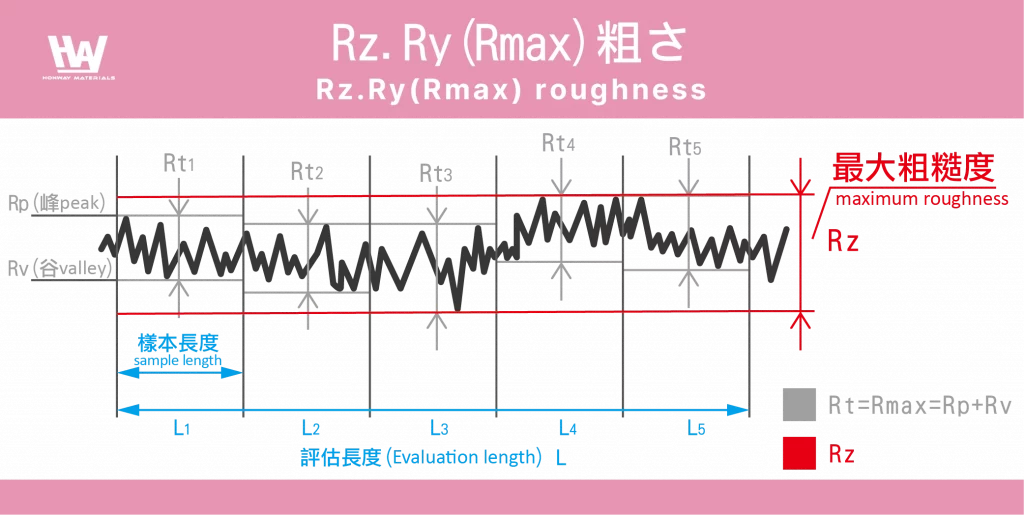

Maximum height roughness (Rmax [DIN]); (Ry [ISO; JIS])

The sum of the highest and lowest troughs within each reference length of the sample length

[Rmax=(Rmax1+Rmax2+……) /N; Ry=Ymax-Ymin]

Ten-point average roughness (Rz)

The average height between the five largest profile peaks and the five maximum profile valleys was taken within the sample length L.

Among the above parameters, Rz and Rmax are slightly different in DIN and ISO.

- Rz(DIN): Take the average total rough height of the five sample lengths.

- Rz (ISO): The average distance between the five highest peaks and troughs in the evaluation length.

※Therefore, the value of Rz(DIN) will be relatively small; Similarly, Rmax (DIN) will also be smaller.

Other Surface Roughness Representations

Other Surface Roughness Representations

| Representations | Definition | Illustrate | |

|---|---|---|---|

| 4 | R3y | Roughness peak-to-valley height | R3y is determined by calculating the minimum distance between the three highest peaks and the three deepest valleys within each sampling length, and then identifying the maximum value from these distances. It is recommended to use at least five sampling lengths for evaluation. |

| 5 | R3z | Average peak-to-valley height | R3z is the average of the vertical distances between the three highest peaks and the three deepest valleys within each sampling length over the entire evaluation length L. |

| 6 | Rv | Maximum trough | Within the sampling length L, from the midline of the profile to the lowest trough. |

| 7 | Rp | Maximum peaks | Within the sample length L, the maximum height of the profile above the average line. |

| 8 | Rc | The average height of roughness of the profile | Within the sample length L, the average height of the profile. |

| 9 | Rda | Arithmetic mean slope of the roughness | Within the sample length L, arithmetic mean of the absolute values of the profile change rate. |

| 10 | RΔq | Root mean square slope of the roughness | |

| 11 | Rku | Probability density function of the roughness kurtosis | Profile peak height |

| 12 | Rlo | The length of the profile where the roughness is measured | Within the evaluation length, the measured length L of the profile surface is the total length over which the probe slides across the surface peaks and valleys during measurement. |

| 13 | Rmr | Roughness material ratio curve | |

| 14 | Rpc | Roughness peak count | |

| 15 | Rsm | The average width of the roughness profile feature | Within the sampling length L, the average spacing between profile elements with respect to the mean line. |

| The Rsm average width refers to the average width value from peak to valley. A larger value indicates a smoother surface, meaning better (smoother) roughness. | |||

| 16 | Rvo | Oil holding capacity of the roughness measurement volume. | |

| 17 | Rs | Average spacing of local peaks in roughness. | |

| 18 | Rq | Root mean square roughness | |

| 19 | RHSC | Count of roughness peaks | |

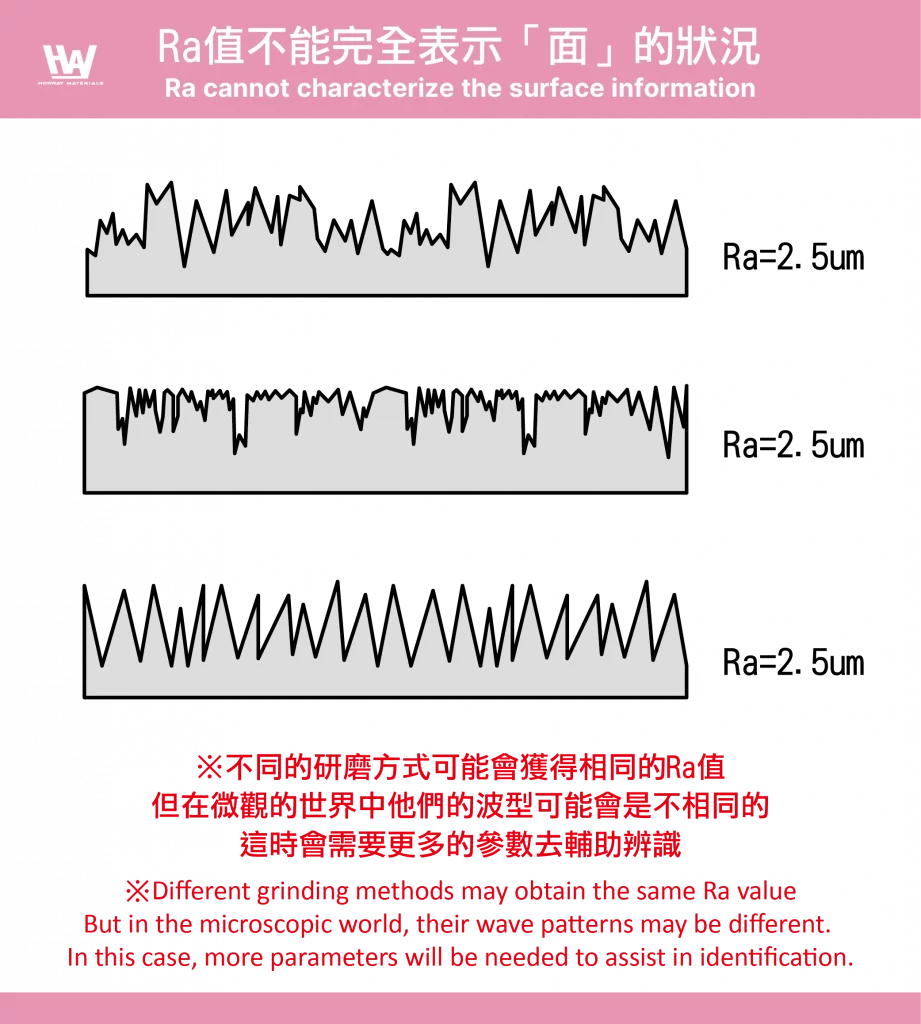

Roughness trap

Conclusion

- Surface roughness is a quantified value of surface texture. From a microscopic perspective, different objects will still have variations in their microscopic form.

- Similarly, different companies and countries use different standard specifications (e.g., ISO, JIS, DIN) for representation. When switching brands or purchasing parts from different manufacturers, it is important to pay close attention to avoid mismatches in dimensions and roughness, which could lead to imperfections in the workpiece or accelerated wear of components.

- Surface roughness is measured by sampling a specific area of the surface. Therefore, when selecting a sample, you should choose a length that represents the surface roughness of the object, or measure multiple areas to reduce error.

- Although there are many technological solutions available on the market to help us save steps in measurement and calculation, understanding the core reasons can better define the problem and help find breakthroughs for current challenges.

Actions

- Does the current measurement of surface roughness meet your expected target?>>> Comparison Table of Grinding and Polishing with Surface Roughness

- Do the workpieces need to be compatible with each other? >>> What are the effects of surface roughness on the workpiece?

- How to solve >>> Six mold polishing techniques: How many do you know?

- Implement >>> polishing abrasives, polishing equipment, polishing tools

- Review

Glossary of Terms

- DIN: Issued by the Deutsches Institut für Normung (DIN) located in Berlin, it is the national standard primarily used in Germany.

- ISO: Developed by the International Organization for Standardization (ISO), it is a universal standard designed to help businesses maintain product and service quality, ensuring stability and consistency. It is also one of the most recognized certifications today, applicable to manufacturers, trading companies, government agencies, and academic institutions across various industries.

- JIS: Developed and reviewed by the Japanese Industrial Standards Committee (JISC), JIS is the most important and authoritative national standard in Japan.

After reading the content, if you still don’t know how to select the most suitable option,

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

TEL: +8867 223 1058

If you have any topics you want to learn more about or if you find it difficult to explain over the phone, feel free to message us on Facebook~

Hongway Facebook: https://www.facebook.com/honwaygroup

您可能感興趣的文章…

[wpb-random-posts]