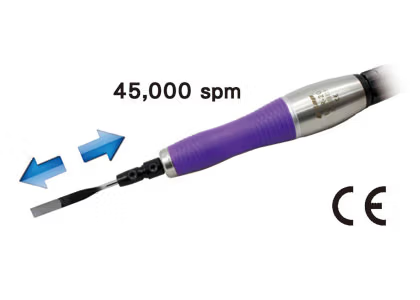

UTR-20 Micro Stroke Turbo Pneumatic Filing Machine

| Journel | Inlet pressure | Weight | Size |

|---|---|---|---|

| 0.15mm | 90psi (6.2kg/cm2) | 190g | Ø28x200L (mm) |

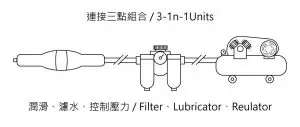

General Assembly

In order to make the pneumatic tool to achieve the best condition and extend its life, need to connect the three points of the combination of use, in order to achieve the purpose of filtering water, control the air pressure and lubrication.

Requirements for improved performance and service life.

In order to make the pneumatic tool to achieve the best condition and extend its life, need to connect the three points of the combination of use, in order to achieve the purpose of filtering water, control the air pressure and lubrication.

- Be sure to check that there is enough lubricant in the oil reservoir of the three-point combination before using the pneumatic tool.

- Setting the intake pressure of the three-point combination at 90psi (6.2kg/cm2) is the most suitable condition for use.

- Before use, please check whether the three-point combined water filter bottle is full, and if it is full, please drain the water first.

- Adjusting the oil intake of the 3-point combination is recommended to be about 2 cc per minute (under regular use).

- If you are on holiday or haven’t used the pneumatic tool for a long time, please increase the lubrication volume of the 3-point combination to 4cc per minute when you start the air tool for the first time, and let the air tool idle at a low speed for 20-30 seconds to let the lubrication oil lubricate each part, and then adjust to the normal speed for the best use.

- Choice of lubricant: Do not use too viscous lubricant, it is recommended to use circulating oil R32.

Operating conditions, start/stop settings:

- The ON/OFF switch is a rotary-type control. With the switch valve body oriented towards the operator, counterclockwise rotation activates the ON state, while clockwise rotation deactivates it (OFF).

※ Prior to operating pneumatic tools, it is imperative to verify that the switch is in the “OFF” state. - When turning on the switch of pneumatic tool, please rotate it 90°, so that the maximum operating speed can be reached. If the angle of rotation is too large, it will not only have no effect but also cause the switch valve to fall off and be damaged.

protective device

Please wear any necessary protective equipment such as ear defenders, goggles, safety apron, helmet, gloves, etc. when using.

Storage of pneumatic tools after use

The tool must be kept in a clean and dry place, and it is recommended to store it in a constant temperature place to avoid sudden temperature changes. Do not put down the pneumatic tool until it has come to a complete stop during operation.

Detailed safety rules and reminders

Safety is a major consideration when using pneumatic tools. Pneumatic tools must be operated under safe conditions, please read the following clauses before use and use pneumatic tools safely.

- This pneumatic tool is designed for industrial purposes such as grinding or engraving and fine polishing, do not use it on the human body!

- Check the air pressure before operation. If the air pressure is lower than 90psi (6.2kg/cm2), the speed and force will be reduced, but if it is higher than 90psi, it will cause overspeed operation, which is very dangerous and will shorten the life of the tool!

- Please use good quality abrasive consumables, do not use damaged or poor quality consumables.

- If the noise index exceeds 85dB(A) while working, the operator must wear earplugs or ear protectors.

- Prolonged use by the operator may cause work injuries due to vibration, especially in the palms and arms. Occupational injuries caused by vibration depend on many factors, such as the type of consumables used, the process, the physical condition of the user, the working environment, working time, temperature and so on. Therefore, operators must construct according to the provisions of ISO5349 when using pneumatic tools.

- When using, pay attention to hair, loose clothes or ties, etc. so as not to be caught by pneumatic tools.

- The working area should be well ventilated, preferably with a dust collector to avoid inhalation of dust or gas discharged from the air compressor.

- If any lubricant gets in the eyes or is accidentally swallowed please go to hospital immediately.

- Do not modify or disassemble air tools without the manufacturer’s permission or consent.

- It is important not to touch the spinning consumables while the pneumatic tool is in operation.

- Make sure that the generated sparks will not hurt people around you or splash flammable substances, etc.

- Make sure that the workpiece being processed has been properly supported or fixed to prevent the workpiece from flying out.

- Do not use air hose other than the standard equipment, and do not pull the air hose violently when using them.

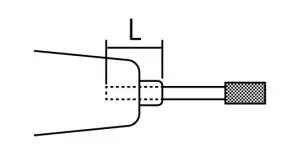

Safety guidelines regarding clamping length, rotational speed, and extension length.

Caution: The clamping length L must not be less than 10mm.

| ØD (mm) | T (mm) | Recommended consumable extension length H (mm) | ||

|---|---|---|---|---|

| 13mm | 25mm | 38mm | ||

| 3.0 | 13 | 105,000rpm | 64,000rpm | 46,650rpm |

| 6.0 | 13 | 60,000rpm | 38,000rpm | 26,250rpm |

| 9.5 | 13 | 45,370rpm | 28,500rpm | 21,000rpm |

| 9.5 | 25 | 26,250rpm | 18,750rpm | 14,250rpm |

| 13 | 13 | 34,500rpm | 22,500rpm | 16,870rpm |

| 13 | 25 | 20,620rpm | 13,870rpm | 10,120rpm |

- L = Clamping length

- H = Consumables protruding length

- T = Abrasive length

- ØD= Grinding rod diameter

Any questions? Contact HonWay