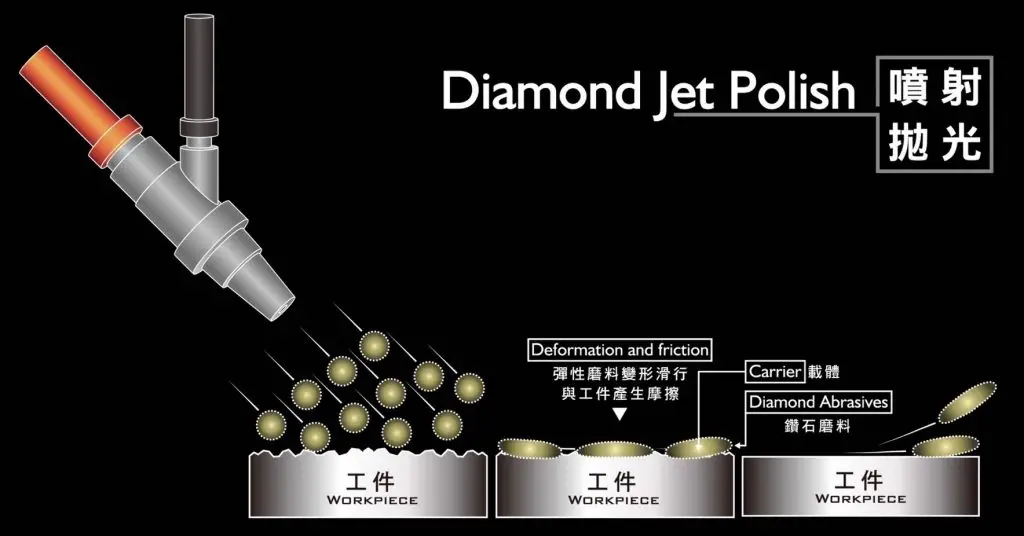

Jet polishing features

As Multi cones are expelled at high velocity via jet polishing systems, the inherent elasticity of the carrier material causes deformation upon impact with the workpiece surface, resulting in a sliding, rubbing motion for polishing.

Suggested: Employ a spray angle of 30°~60° relative to the workpiece surface during polishing.

Features: The polishing action is facilitated by frictional forces that induce diamond powder from the elastic abrasive particles to polish the workpiece. The instantaneous impact of numerous elastic abrasive particles on the workpiece surface, coupled with their inherent tendency to slide along the contours of the workpiece, enables rapid and precision-preserving polishing and grinding of workpieces with complex geometries.”

Abrasive Characteristics

Multi cone (composite abrasive particle) is a porous self-adhesive abrasive material. It is made of plastic, rubber fiber, and porous ceramic, and is an elastic composite (particle size approximately 0.5~2mm).

Utilizing the adhesion of its own elastomer, it allows abrasives (diamond powder) to naturally adhere to its surface and porous structure through physical and chemical actions.

Jet polishing mechanism diagram

Related Equipment

|

|

|

AS-JP23L |

AS-JP23 |

Any questions? Contact HonWay