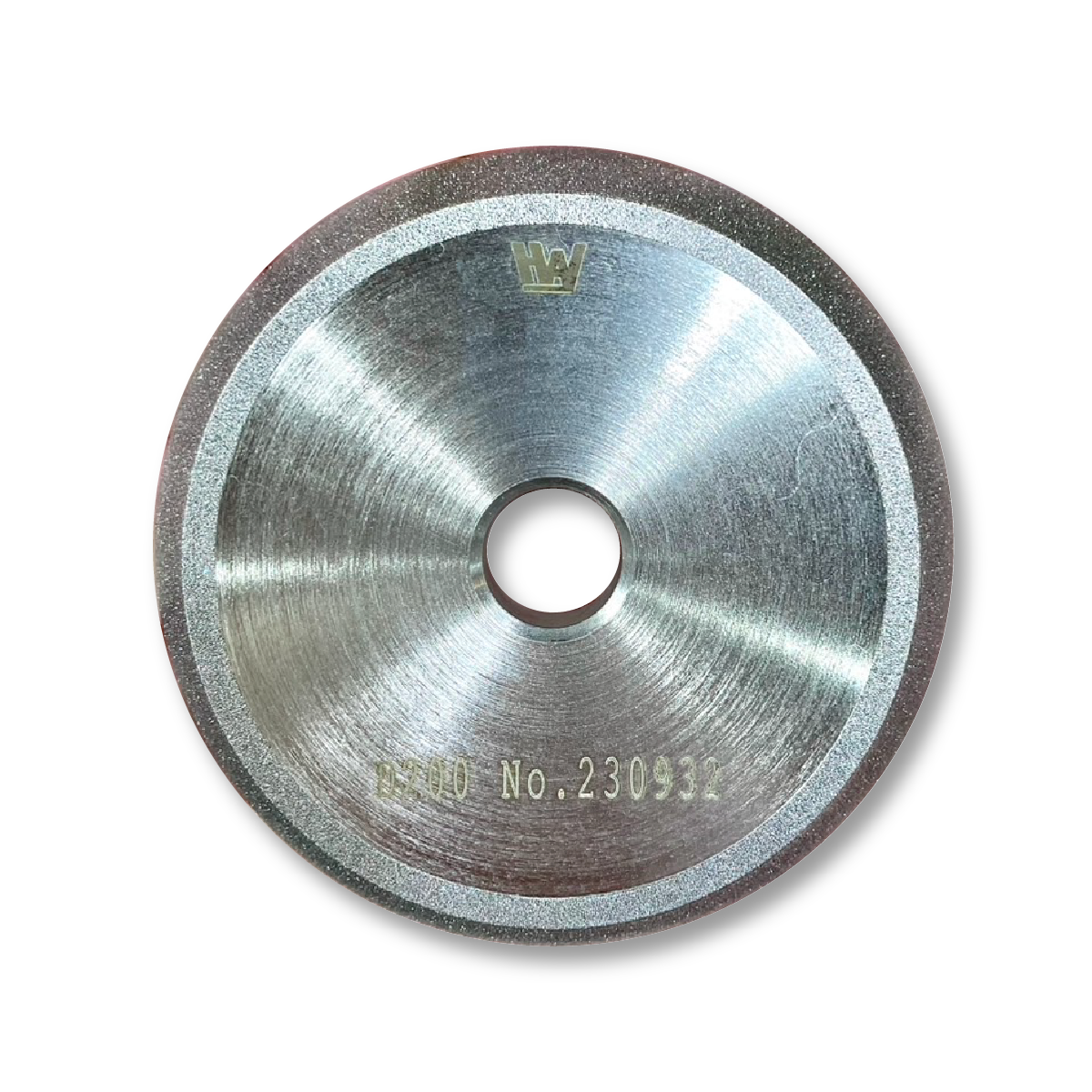

Electroplated diamond grinding wheel

- Compared with grinding wheels of other bonding methods, electroplated grinding wheels have higher abrasive concentration and abrasive protrusion, and have very sharp and high grinding capacity characteristics.

- Without the limitation of molds, grinding wheels of various shapes can be made, and the external dimensions of the grinding wheels hardly change, making them suitable for form grinding.

Application areas

- Jig Grinding : Most commonly used in precision ceramics and quartz molding, customized products can be provided according to different needs, with grain sizes ranging from #80 to #325 to meet the needs of roughing and fine processing.

- Touch Glass Processing : Drilling and chamfering of glass panels in smart phones and tablet PCs, combining different grits in the same electroforming rod to improve work efficiency.

- Tool Grinding: Both milling cutter and drill grinding machines are equipped with electroplated grinding wheels. Tungsten steel can be ground with diamond abrasives, while high-speed steel can be ground with CBN (Cubic Boron Nitride) abrasives.

- Form Grinding : Electroforming can make any different shapes with small deformation, so it is suitable for form grinding, and it can also be made into dressing blocks to dress Aluminum Oxide grinding wheels.

- Suitable for grinding and forming tungsten steel tools.

Product features

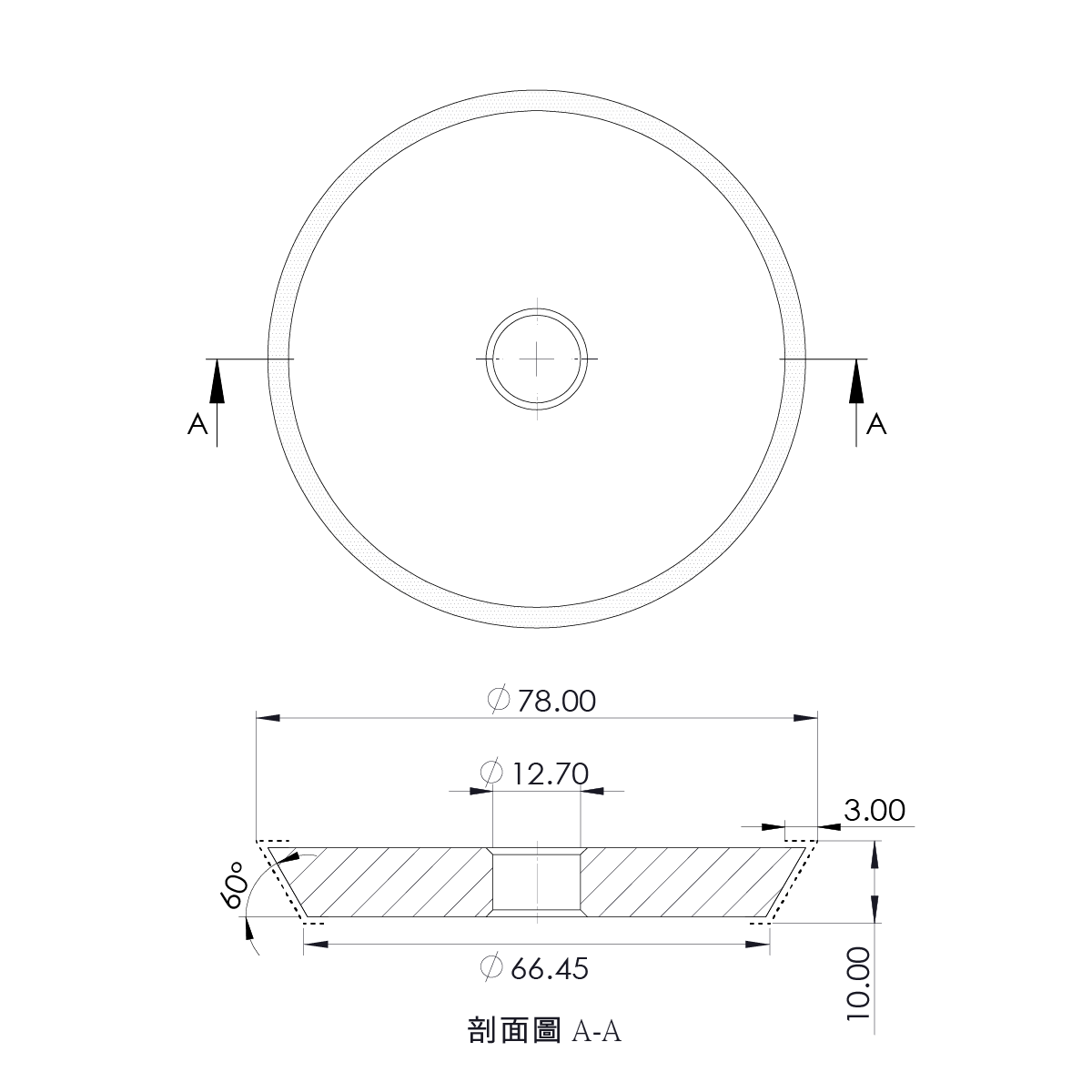

※The dots and dashed lines in the diagram indicate the positions where the abrasive is attached.

Grit number: 200#

Unit : mm

Any questions? Contact HonWay