Cerium Oxide Polishing Solution

- Larger cerium oxide particles have greater grinding power and are more suitable for harder materials; while glass applications tend to use finer polishing fluids.

- One important point to note is that all cerium oxide particles have a distribution issue. The average particle size or median diameter (D50) determines the polishing speed, while the maximum particle size (Dmax) determines the polishing precision.

- To achieve high precision, the maximum particle size of the polishing powder must be controlled.

- The powder has good particle suspension properties, making it less likely to scratch the surface of objects. It can be used to polish optical glass, smartphone glass, and more.

Features:

- Moderately soft and hard, it does not scratch the surface of polished objects.

- It has excellent suspension performance, making it resistant to settling.

Applications:

- Precision optical devices, hard disk substrates, LCD displays, high-precision optical glass polishing.

- Optical lenses, fiber optic connectors, microcrystalline glass substrates, and crystal surfaces.

Product specifications:

| model | Product Status | Particle size(um) | use | ||||

| ordinary blue glass | White optical glass | panel glass | optical components | blue glass | |||

| RA-10 | white liquid | D50/0.8 | ● | ● | |||

| RA-08 | white liquid | D50/1.0 | ● | ● | ● | ||

| RA-01 | white liquid | D50/1.5 | ● | ● | ● | ||

| RA-12 | white liquid | D50/2.0 | ● | ||||

| HAT-1205 | Red liquid | D50/1.2 | ● | ● | |||

| HAT-1805 | Red liquid | D50/1.8 | ● | ● | |||

| RGB-1935 | Polishing liquid | D50/0.5 | ● | ● | |||

| RGB-1938 | Polishing liquid | D50/0.8 | ● | ● | |||

Cerium Oxide Polishing SolutionFor special usage specifications or customized requirements, please call or email us. Thank you.

Precautions:

General precautions:

- Carefully read the Safety Data Sheet (SDS): Before using cerium oxide, be sure to read the safety data sheet provided by the supplier in detail to understand its potential hazards, safety handling measures, and emergency response methods.

- Avoid inhaling dust: Cerium oxide may exist in powder form, and inhaling the dust may irritate the respiratory tract. Ensure good ventilation during handling, or wear appropriate respiratory protective equipment (such as a mask).

- Avoid contact with skin and eyes: Cerium oxide may irritate the skin and eyes. Wear protective gloves and goggles when handling. If contact occurs, immediately rinse with plenty of water.

- Thorough cleaning after handling: After handling cerium oxide, be sure to thoroughly wash your hands and any clothing that may have come into contact with it.

- Eating and smoking are prohibited in the workplace: Avoid eating and smoking in areas where cerium oxide is handled to prevent accidental ingestion or inhalation.

- For laboratory or industrial use only: If it is reagent-grade cerium oxide, do not consume it; it is for laboratory or industrial use only.

- Storage Precautions: Store cerium oxide in a sealed container in a dry, cool, and well-ventilated place, avoiding moisture absorption, clumping, or contamination. Avoid storing with incompatible substances.

- Waste disposal: Cerium oxide waste shall be disposed of in accordance with local regulations.

Precautions for specific applications (taking polishing as an example):

- Choosing the appropriate grit size: Select cerium oxide polishing powder with a suitable grit size based on the hardness of the polishing material and the required polishing precision. Larger grit sizes offer stronger grinding power and are suitable for harder materials or rough polishing; finer grit sizes are suitable for fine polishing to achieve a higher surface finish.

- Pre-use inspection: Ensure the polishing powder is dry and free of contamination to avoid affecting polishing quality or scratching the workpiece.

- Surface polishing: When polishing, keep the operation on a flat surface and avoid using the sides to ensure uniform polishing.

- Keep moist: During the polishing process, it is necessary to continuously replenish water or cerium oxide polishing fluid to avoid overheating and excessive dust generation, and to help suspend the polishing powder.

- Avoid over-polishing in the same spot: Polishing in the same spot for a long time or with excessive force may cause localized overheating or unevenness.

- Cleaning after polishing: The workpiece should be cleaned immediately after polishing to remove residual polishing powder and avoid contamination or further scratches.

- Choose the right polishing pad: Select a polishing pad with the appropriate material and hardness based on your polishing needs to achieve the best results. Harder wool pads are suitable for stronger abrasion, while softer materials are suitable for fine polishing.

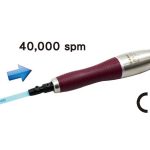

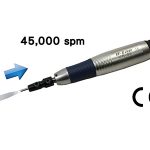

- Power tool usage: When using power tools for polishing, adjust the speed and pressure appropriately according to the requirements of the tool and the workpiece. For glass scratch removal, low-speed polishing is recommended.

- Large-area scratches: For large-area or deep scratches, we recommend talking to us or trying other polishing products (such as nano diamonds).

Want to know more details?>>>[Complete Guide] Cerium Oxide Polishing Powder/Slurry: Properties, Applications, and Selection Tips

Any questions? Contact HonWay