Apick Solution-AS 4100,AS 5190

Product features:

- Easy-to-Use Interface

- Equipped with uninterruptible power system protection measures

- Polishing automation

- Polishing path compensation design

- Enhance the efficiency and stability of polishing.

- Realization of free-form ultra-precision polishing head

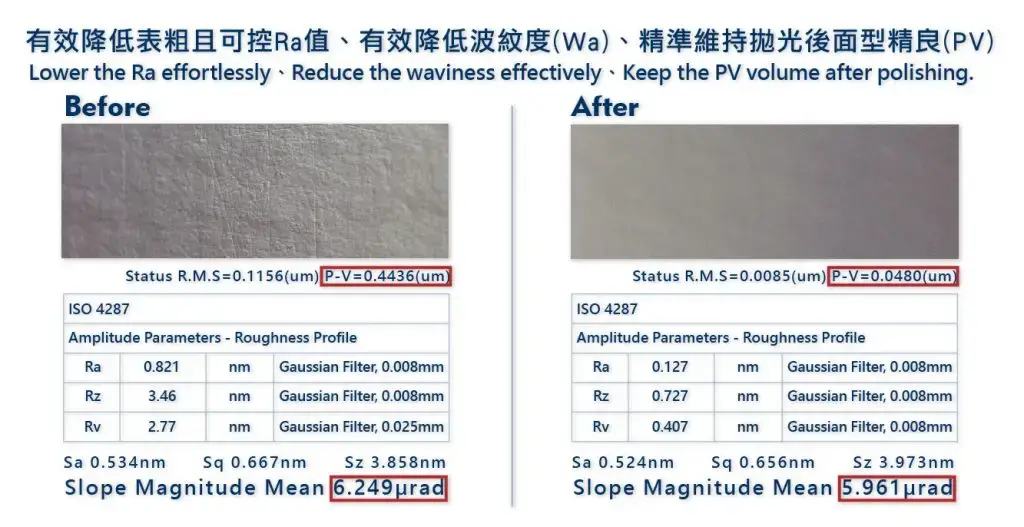

- No polishing marks or rainbow stripes under the microscope.

- Please contact sales for applicable materials

Polishing capacity:

Product specifications:

| Model | AS-4100 | AS-5190 |

| Number of axes | X, Y, Z three linear axes + one rotary axis (B) | X, Y, Z three linear axes + two rotary axes (B, C) |

| Performance characteristics | Improve the accuracy, quality and efficiency of free space curvature, and can perform rotational processing | Can reduce the need for tools and fixtures, reduce manufacturing costs, and process extremely complex surfaces and multi-angles, and can complete multiple surfaces at one time |

| Applicable workpieces | Parts with rotating features, such as shafts and housings | Parts with complex curved surfaces, such as aviation parts, medical equipment, and precision molds |

| Applicable industries | automotive industry, aerospace technology, energy industry | aerospace technology, medical equipment, scientific research and development |

| Specification | ||

| Device size | 960×798.5x1750mm | 860x980x1780mm |

| X/Y/Z stroke processing area | 400x400x170mm | 190x190x300mm |

| Workpiece size | 400x230x150mm | Ø 200x250mm |

| Maximum machining angle | 30° | B axis: -115° ~ 15°, C axis: 360° |

| Loadable workpiece weight | 5 kg | 15 kg |

| Software analysis | 0.001 | 0.001 |

| Spindle motor | 750W permanent magnet synchronous motor | 750W servo motor |

| Spindle speed | 80-600 RPM | 0-3000RPM |

| Equipment voltage | Single-phase 220 VAC | Single-phase 220 VAC |

| Device current | 10A | 10A |

| Equipment energy consumption | ≈500W | ≈600W |

| Equipment weight | ≈450Kg | ≈480Kg |

Any questions? Contact HonWay