Introduction to Chemical Eement Zinc

Zinc (Chemical Symbol: Zn) is a transition metal that was historically referred to as “Dwarf lead” due to its resemblance to lead in both shape and color. At room temperature, zinc is a hard and brittle metal with a blue-silver luster. It exhibits excellent malleability, wear resistance, and corrosion resistance, and demonstrates remarkable mechanical properties at ambient temperatures. Zinc can also form high-performance alloys with various metals. Its applications are broad, primarily appearing in the form of galvanization, zinc-based alloys, and zinc oxide, used in industries such as automotive, construction, household appliances, shipbuilding, light industry, machinery, and batteries. Currently, zinc ranks third in the non-ferrous metals market, following copper and aluminum.

Table of Contents

Common Issues about Polishing Zinc

1. Common Applications of Zinc

Galvanizing: It is a surface treatment technology that involves applying a layer of zinc to the surface of a metal or alloy to improve its appearance and enhance its corrosion resistance. The most commonly used method is hot-dip galvanizing, where the substrate is immersed in molten zinc to form a strong protective layer. This technique is widely used in industries such as construction and automotive.

Zinc Alloy: Zinc itself has low strength and hardness, but when alloyed with metals such as aluminum and copper, its performance can be significantly improved. Its creep resistance can also be greatly enhanced, especially in zinc-copper-titanium alloys, which have mechanical properties close to those of aluminum alloys and brass. These zinc alloys, due to their excellent superplastic properties, are widely used in the production of die-cast components and parts in the automotive and machinery industries.

*Creep: Also known as deformation, creep refers to the phenomenon where a material undergoes slow and permanent deformation when subjected to stress below its yield strength over an extended period. This effect is especially pronounced at elevated temperatures.

Zinc Batteries: Zinc can be used to manufacture batteries, such as carbon-zinc batteries and the more recently developed zinc-air batteries.

2. Advantages of Zinc

Low Melting Point: Zinc has a relatively low melting point (around 419°C), making it easier to process and work with during manufacturing.

Good Ductility: Zinc exhibits good ductility, allowing it to be processed through processes such as rolling, extrusion, and forging when heated. This enables the formation of thin sheets or various shaped products, making it highly versatile for manufacturing applications.

Corrosion Resistance: Zinc has excellent corrosion resistance and is commonly used in galvanizing treatments. This effectively prevents rust and corrosion on steel and other metal surfaces, enhancing the longevity and durability of the materials.

3. Common imperfections

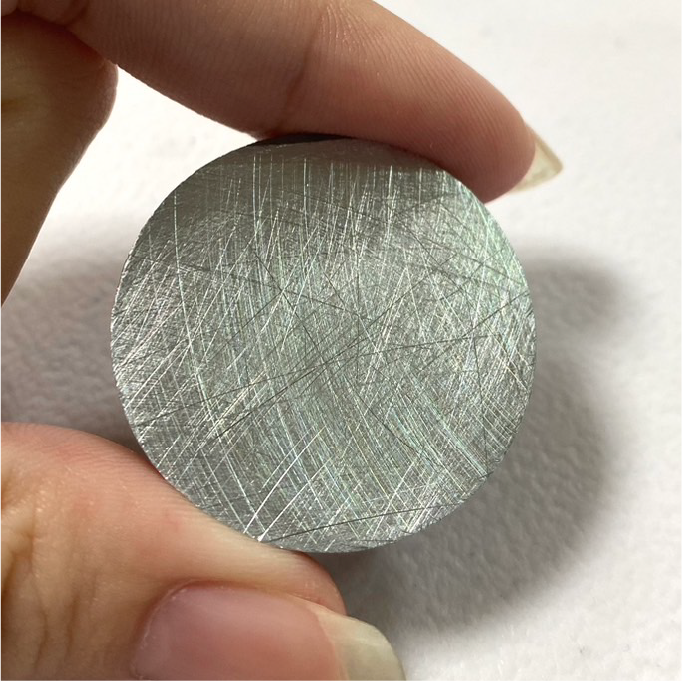

Scratches: After grinding, zinc materials may stick to the abrasive surface, causing scratches as the tool rotates, making it difficult to improve the glossiness.

Polishing Burn Marks: Excessive friction or pressure during polishing may cause high-temperature burn marks on the zinc alloy surface, leading to the appearance of dimples and uneven color.

Pores and Defects: In zinc alloy materials, pores or other material defects may become more apparent after polishing. These pores are often caused by bubbles during the casting process.

4. Difficulties in polishing zinc compared with other metals

Low Hardness: Zinc has lower hardness compared to other metals. If the speed is too high during polishing, it is easy to cause scratches and indentations.

Low Melting Point: When polishing at high speeds or with excessive pressure, high temperatures can cause uneven surface color.

Zinc Polishing Experiment

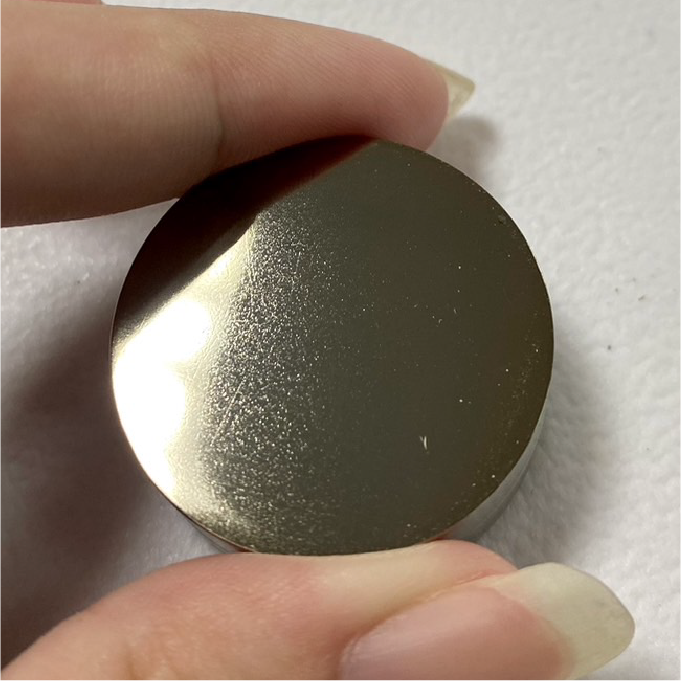

Zinc is a metal with excellent corrosion resistance and formability. It is commonly used in die-cast parts in the automotive and mechanical industries.

However, challenges such as scratches, pores, and burn marks frequently arise during the polishing process, negatively affecting the final surface finish and appearance.

To effectively address these issues, Hongwei Laboratory conducted experiments on mechanical polishing of zinc. We explored how different polishing techniques and conditions influence the polishing results.

In the experiments, we evaluated the selection of polishing tools and compounds, aiming to optimize the polishing process, improve the surface finish of zinc, and enhance its performance in practical applications.

Tools Preparation

1. Metallographic Grinding and Polishing Machine

2. Grinding disc: such as: electroplated diamond grinding disc (400#), diamond resin grinding disc (400#.1000#).

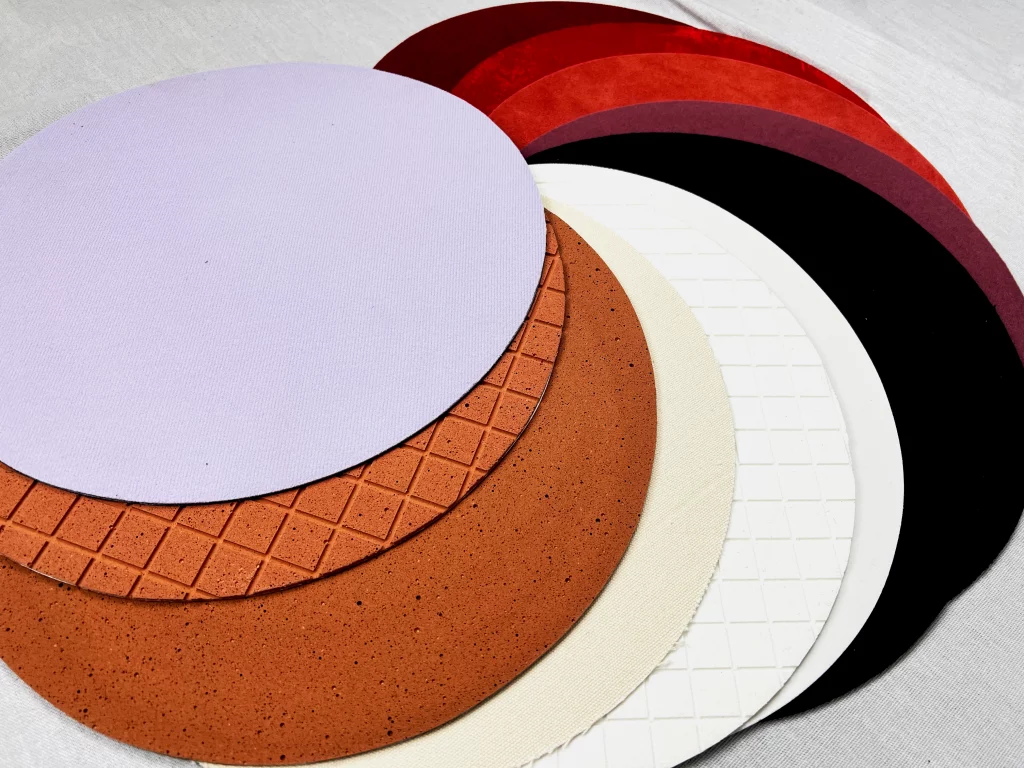

3. Polishing pads: such as: cerium oxide leather polishing pads, silk polishing pads and other models with different abrasive materials.

4. Polishing solution: such as: nano diamond polishing fluid 15um.3um.0.5um, used in combination.

Polishing Processes of Zinc

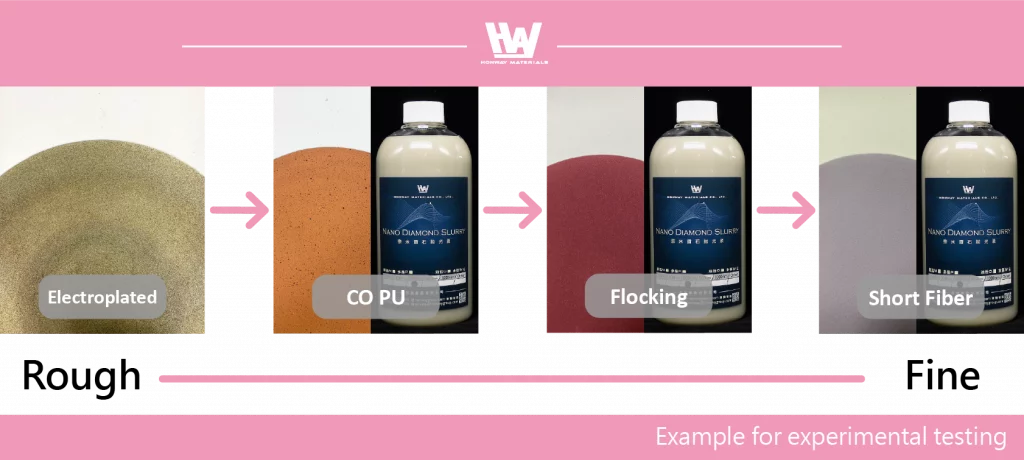

Electroplate diamond grinding disc + water > Diamond resin grinding disc + water > Cerium oxide polishing pad + diamond solution > Silk polishing pad + diamond solution

Polishing Issues in Experiment

During the mirror polishing process of zinc, improper application of speed and pressure can easily lead to the formation of new scratches. Careful observation and adjustments are necessary to achieve the optimal working conditions.

Recommended Polishing Tools

Nano diamond polishing solution / Grinding solution / Suspension >>>Polishiing solution

- Best suited for: mechanical operation

- State: liquid (oil-based/water-based/alcohol-based)

- Polishing can be performed using a double-sided grinding machine, chemical mechanical polishing (CMP), or metallographic grinding.

- ※ Since the abrasive is in a free state, it is suitable for large-scale polishing.

- ※ If the surface of the workpiece is still rough, choose a polishing liquid with larger particles.

Polishing pad / Grinding pad >>>> Metallographic consumables

- Materials:

- Contains abrasive: Cerium oxide polishing pad, Diamond resin grinding disc, Electroplate diamond grinding disc

- Does not contain abrasive: Silk, Short fiber velvet, Polyurethane (black velvet), Weave, Fluff, Porous, Hard cloth, Soft cloth, etc.

Conclusion

Zinc metal is widely used in various industries, such as automotive, construction, household appliances, ships, light industry, machinery, and batteries, due to its excellent malleability, corrosion resistance, and low melting point, as well as its ability to form high-performance alloys with other metals. Understanding the causes of common issues like porosity, burn marks, and scratches in zinc polishing allows for the selection of appropriate polishing tools and methods. This not only helps in reducing production costs but also significantly decreases processing time.

Action

- Does the current measurement of surface roughness meet your expected target? >>> Comparison Table of Grinding and Polishing with Surface Roughness

- Common problems and solutions about metals>>> Metal Polishing Defect Repair Guide: Common Problem Solutions and Recommended Quality Materials and Tools

- How to solve >>> Six mold polishing techniques: How many do you know?

- Implement >>> polishing abrasives, polishing equipment, polishing tools

- Review

We offer customized adjustments to the grinding process, tailored to meet processing requirements for maximum efficiency.

After reading the content, if you still don’t know how to select the most suitable option,

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have a subject that you want to know or a phone call that is not clear, you are welcome to send a private message to Facebook~~

Honway Facebook: https://www.facebook.com/honwaygroup