Abrasives are substances that are used to grind, cut, polish, or remove materials, and usually have a high hardness. Diamond, as a superhard material, is one of the most commonly used abrasives.

Table of Contents

Introduction to diamond abrasives

- Chemical composition: Natural diamond is a crystalline state of carbon, which is an allotrope of carbon with graphite, and the main impurity is N (0.01~0.25%).

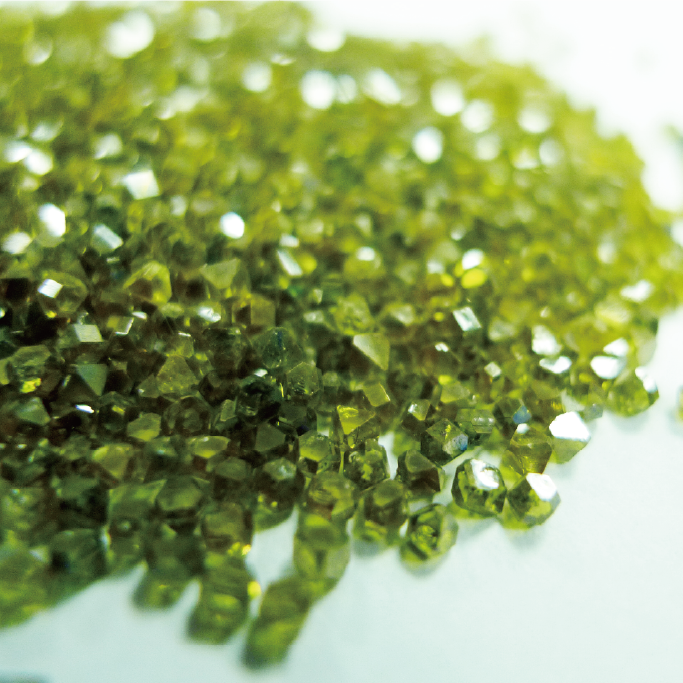

- Color: Pure diamond is transparent and colorless, but can display different colors due to various impurities and crystal defects. Natural diamonds are mostly light yellow, while synthetic diamonds are yellow-green.

- Physical properties: high melting point, high thermal conductivity, high resistivity, density ρ= 3.51524g/cm3.

- Chemical properties: hydrophobic, lipophilic, inert at room temperature, and resistant to chemical reagents except for certain oxidizers when heated to 1000℃.

- Oxidation: When the temperature of diamond is above 600℃ in pure oxygen, the diamond begins to lose its luster and the black surface turns to ashes. It starts burning at 700~800℃.

- The temperature at which F0 synthetic diamonds begin to oxidize in the air is 740~840℃, and the ignition temperature is 850~1000℃.

Types of diamond abrasives

Natural Diamond (D): These abrasives come from natural diamond ore, possessing higher purity and hardness.

Synthetic Diamond (SD): Also known as synthetic diamond, it is artificially synthesized through high temperature and high pressure technology, relatively low in price, but can match the performance of natural diamonds.

Synthetic Metal Coated Diamond (SDC): It is a specially treated diamond abrasive that enhances performance and application range by coating the diamond surface with a layer of metal film such as nickel, copper, or cobalt.

Properties of diamond abrasives

Ultra High Hardness: Diamond is the hardest natural material in the world, with a Mohs hardness of 10, which gives it unparalleled advantages in cutting, grinding, and polishing processes. It can effectively handle various materials with higher hardness, such as tungsten steel, glass, ceramics, and stone.

High wear resistance: The wear resistance of diamonds is also very prominent, allowing for long-term use without rapid wear, which enables it to maintain high efficiency during prolonged grinding processes.

Chemical Stability: Diamonds are chemically stable under normal temperature and pressure, and are not easily reactive with most chemical substances.

※Supplement: Diamonds undergo chemical reactions with iron group elements such as iron, nickel, and cobalt in high-temperature environments, due to the strong affinity of iron group elements for carbon. As the temperature rises, these metals can catalyze the decomposition of diamonds into carbon atoms, forming carbides with the metals or being dissolved in the metals. This reaction accelerates the wear of diamonds, reducing their hardness and durability, making them unsuitable for processing materials containing iron group elements.

High temperature resistance: When the grinding temperature >600℃, diamonds will dissolve in certain elements such as rare earth elements, La, Ce, or synthesize carbides with certain elements such as heat-resistant transition elements, Ti, Zr, which accelerates the wear of the grinding wheel and makes it unsuitable for processing.

Synthetic equipment and raw materials for synthetic diamonds

The main methods for producing synthetic diamonds are 1. high temperature and high pressure 2. explosion method 3. CVD

High-Temperature High-Pressure Method: It is a synthetic diamond produced by simulating the conditions under which natural diamonds form. This method replicates the high-temperature and high-pressure environment found deep within the Earth’s crust, allowing carbon atoms to crystallize into a diamond structure, with production conditions typically requiring a high pressure of 10 GPa and a high temperature of 3000°C.

(Further reading: Diamond Synthetic Method ─ High Temperature and High Pressure)

Hydrostatic method: Including hydrostatic catalyst method, hydrostatic direct conversion method, and seed catalyst method. It is used in the production of abrasive-grade man-made diamonds and the synthesis of gem-quality diamonds.

Dynamic pressure method: Including explosive strong, liquid discharge method, directly converted into hexagonal diamond. The explosion method is used in the development of nanoscale diamonds.

(Read more: Diamond Synthesis Method – Explosion )

Methods for growing diamonds in substable regions: Includes chemical vapor deposition (CVD), liquid phase epitaxial growth method, gas-liquid-solid phase epitaxial growth method and normal pressure and room temperature synthesis method. The vapor deposition method is mainly used for the development and application of microcrystalline diamond and nanodiamond films.

((Read more: Diamond Synthesis Method – Chemical Vapor Deposition)

Application of diamond abrasives

Cutting and grinding: Diamond abrasives are often used for cutting, grinding and polishing hard materials, diamond grinding tools such as: diamond grinding wheels, diamond grinding rods, diamond turning tools, etc.

Polishing: Diamond abrasives are widely used in polishing and are mainly used for ultra-precision surface treatment of high-hardness materials. Due to the ultra-high hardness and fine cutting ability of diamonds, nanometer surface finishes can be achieved, making them suitable for polishing materials such as glass, ceramics, cemented carbide and gemstones.

Ultra-precision machining: Diamond abrasives are used in microfabrication, such as the manufacture of electronic components and optical components, to the micron level.

High temperature resistant industry: Due to the high heat resistance of diamond, it is also widely used in some abrasives in high-temperature environments, such as the manufacture of aerospace and automotive industries.

Action

- How to choose grinding wheel>>>How to Choose Between Diamond Wheels and CBN Wheels?

- The basic knowledge of abrasives that must be known>>>Grinding-Abrasive Introduction

- Whether the current measured surface roughness meets your expected goals>>>Comparison Chart of Grinding Polishing and Surface Roughness

- How to choose a synthetic diamond?>>>How synthetic diamonds are made

- Action>>>Diamond and CBN grinding wheel, Polishing abrasive, Polishing Equipment, Polishing Tools

- Review

Honway focuses on the fields of mechanical polishing, superhard abrasives and rare earth raw materials, and is committed to providing customers with polishing solutions with lower environmental pollution. If you have related needs or want to know more, please feel free to contact us! Working together for a sustainable future.

We offer customized adjustments to the grinding process, tailored to meet processing requirements for maximum efficiency.

After reading the content, if you still don’t know how to select the most suitable option,

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have a subject that you want to know or a phone call that is not clear, you are welcome to send a private message to Facebook~~

Honway Facebook: https://www.facebook.com/honwaygroup