Table of Contents

Introduction

Workpiece polishing is the most important process in the manufacturing industry, especially in the production of molds, the quality of polishing directly affects the accuracy, appearance and service life of the product. However, various kinds of defects, such as scratches, uneven roughness, oxidized spots, etc., will inevitably appear during the polishing process, which not only reduces the quality of the molds, but also leads to an increase in the failure rate of the products. It is very important to understand and how to repair these defects effectively.

Common Flaws and Causes

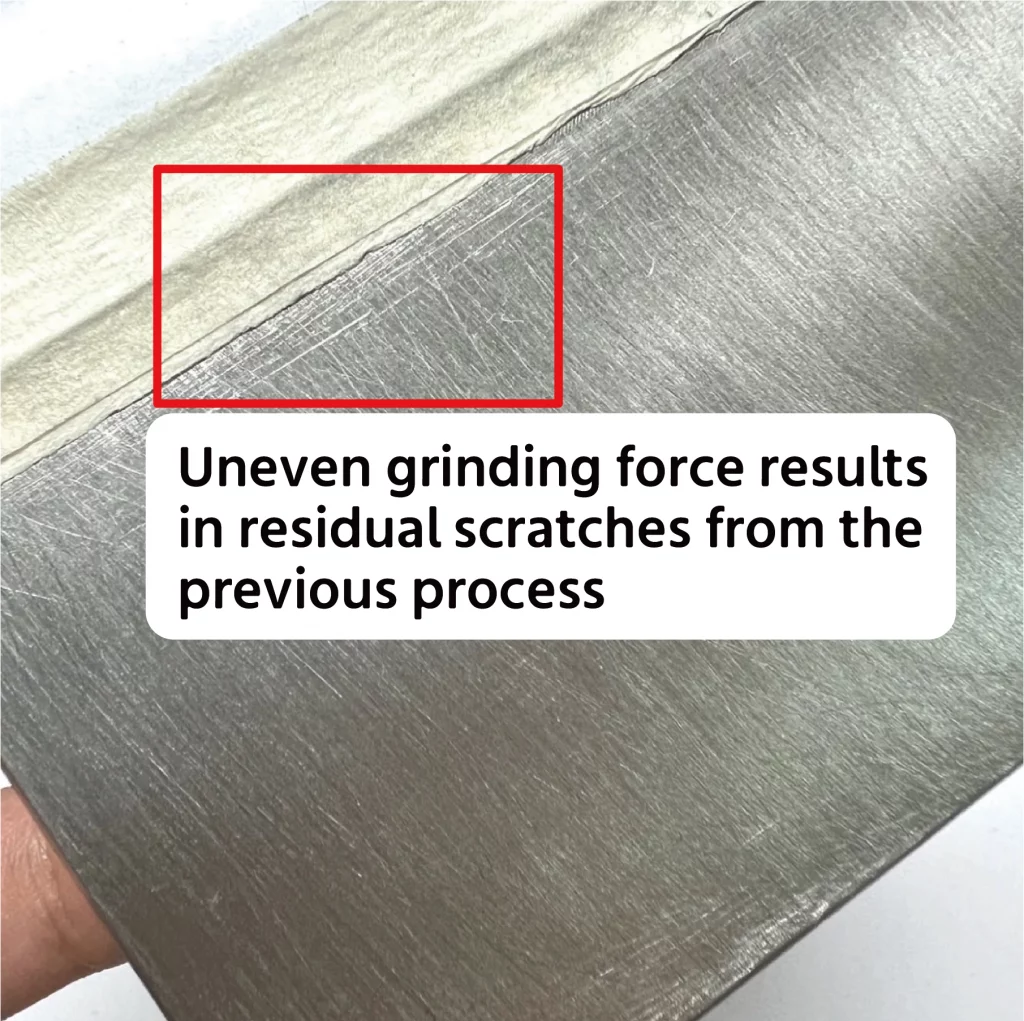

Scratches: Scratches are usually caused by improper selection of polishing tools or materials. Coarse polishing particles or worn tools can leave fine scratches on the mold surface.

Uneven roughness: Inconsistent pressure distribution during the polishing process, poor time control, or the use of unsuitable polishing materials can lead to uneven surface roughness on the mold.

Oxidation spots: Some metals may develop oxidation spots on the surface after polishing, especially if the mold was not cleaned in time or if the environmental humidity is too high, affecting both appearance and performance.

(The surface roughness in the image has already reached the desired level, but due to improper storage, oxidation spots have appeared, requiring an additional cleaning process to remove them.)

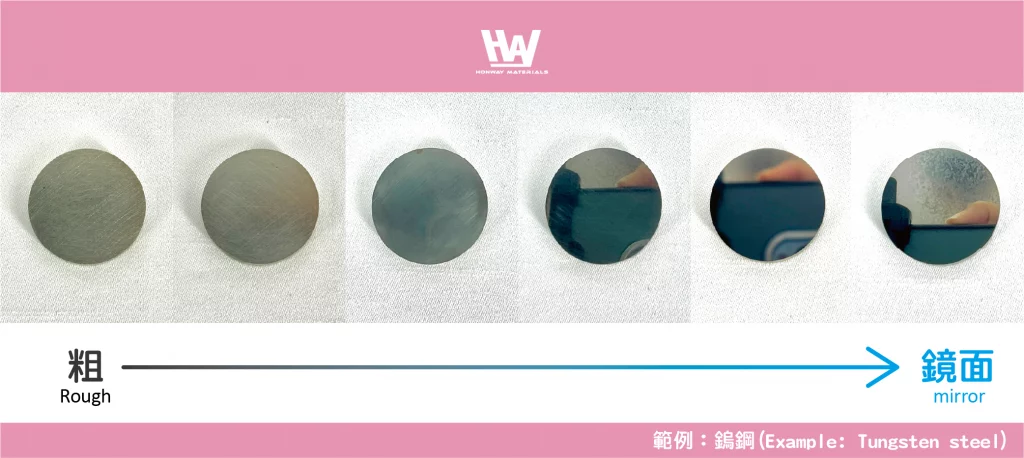

Insufficient surface roughness: If the chosen polishing material has particles that are too coarse, or the polishing process did not achieve enough fineness, the workpiece surface will not reach the required level of smoothness.

Restoration Program

1. Scratches Restoration

︎︎ Tool inspection and replacement: Regularly check the condition of polishing tools to ensure undamaged tools are being used.

If scratches are observed, you can either extend the polishing time at the current stage to test if it reduces surface scratches or return to the previous step for re-polishing before proceeding. If the issue persists, consider using finer polishing materials and gradually reduce the particle size until the scratches disappear.

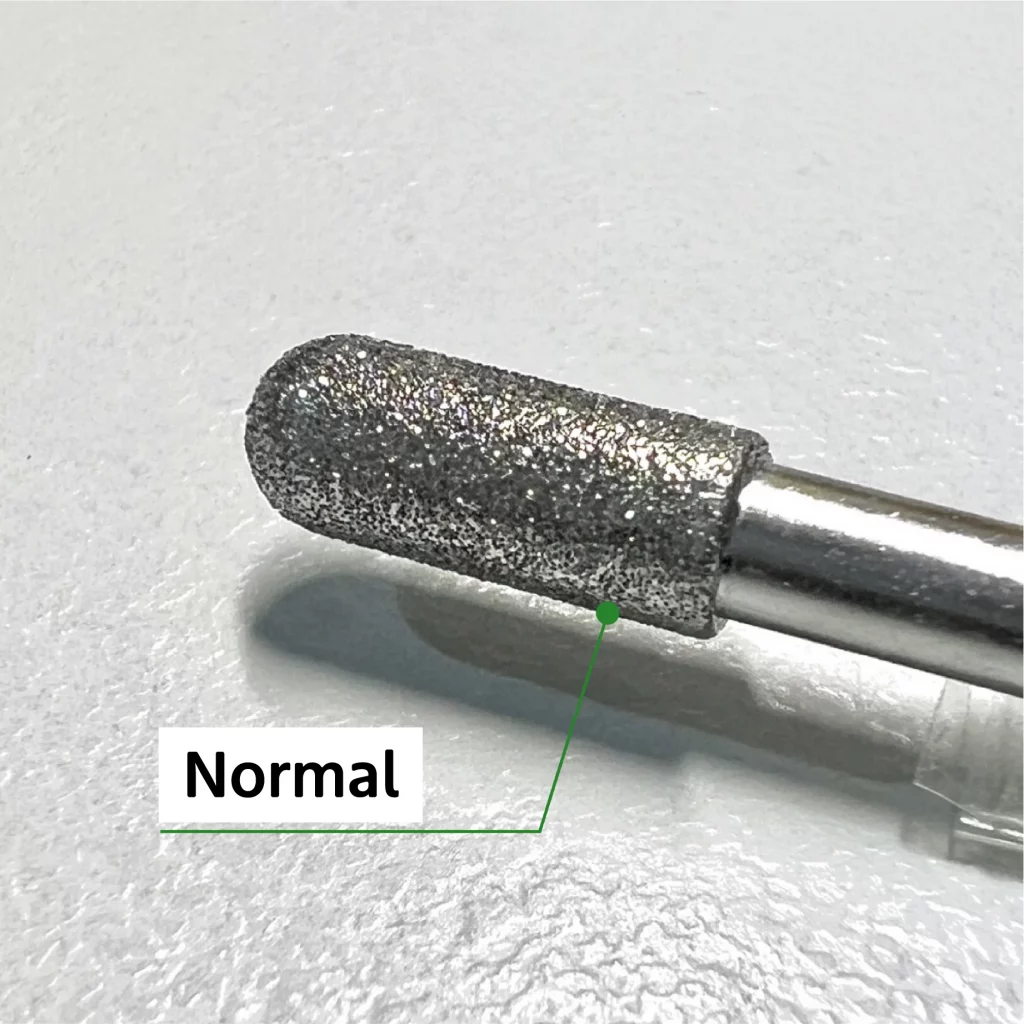

(Right image shows a diamond electroplated grinding wheel with grain shedding, while the left image shows a normal diamond electroplated condition.)

—(If grain shedding occurs, it is recommended to stop using the wheel immediately and contact a professional manufacturer for custom re-electroplating of the grains)—

—(Uneven grains may cause the need for more time-consuming repairs later)—

—(For other types of bonded grinding wheels, if cracks appear, we at HongWei also advise against continuing their use)—

︎Multi-step polishing: Begin with rough polishing and gradually transition to fine polishing to avoid deep scratches from a single polishing step.

2. Uneven Roughness Restoration

︎Pressure and time control: Adjust the pressure and timing during the polishing process to ensure uniform polishing. Using automated polishing equipment can improve stability.

︎Material selection: Use polishing consumables that suit the characteristics of the tool material, and replace materials during the polishing process as needed to achieve a uniform surface finish.

3. Oxidation Spots Restoration

︎Cleaning and environmental control: Clean the mold surface immediately after polishing and store it in a dry environment. Anti-rust oil can be applied to protect the surface after polishing.

︎Localized polishing: For oxidation spots that have already formed, localized polishing can be used to restore the surface. Use fine polishing materials to remove the oxidized layer.

4. Surface Roughness Restoration

︎ Material refinement: Use finer polishing materials and gradually refine the grain size during the polishing process, from rough to fine polishing, to achieve a higher surface roughness.

︎Multi-polishing techniques: Employ multiple polishing techniques during the process, such as jet polishing or ultra-fine grinding, to improve surface roughness.

Choosing Suitable Restoration Materials and Tools

When selecting polishing repair materials, procurement should consider the current stage of production, encountered issues, the material of the workpiece, defect types, and the required surface roughness standard. High-quality polishing consumables and tools can effectively reduce the occurrence of defects and improve repair efficiency.

Recommended Materials

︎ Polishing paste and polishing liquid: These are suitable for the final polishing of high-precision molds, offering extremely fine particles for a mirror-like finish.

Polishing compound >>> Polishing compound

- Best suited for: manual operation

- State: paste form

- Polishing can be done using a short-fiber wiping cloth (for high precision), wool wheels (for rough polishing), or hand tools, making it ideal for small areas and detailed work. It can also be used in mechanical polishing.

- ※When the paste turns black after polishing, this is a normal occurrence. Simply wipe off the oxidized material and grease with a tissue or paper towel soaked in alcohol.

- ※Since the abrasive is in paste form, it is more suitable for small-scale and fine polishing.

Polishing solution / Grinding solution / Suspension >>> Polishing solution

- Best suited for: mechanical operation

- State: liquid (oil-based/water-based/alcohol-based)

- Polishing can be performed using a double-sided grinding machine, chemical mechanical polishing (CMP), or metallographic grinding.

- ※ Since the abrasive is in a free state, it is suitable for large-scale polishing.

- ※ If the surface of the workpiece is still rough, choose a polishing liquid with larger particles.

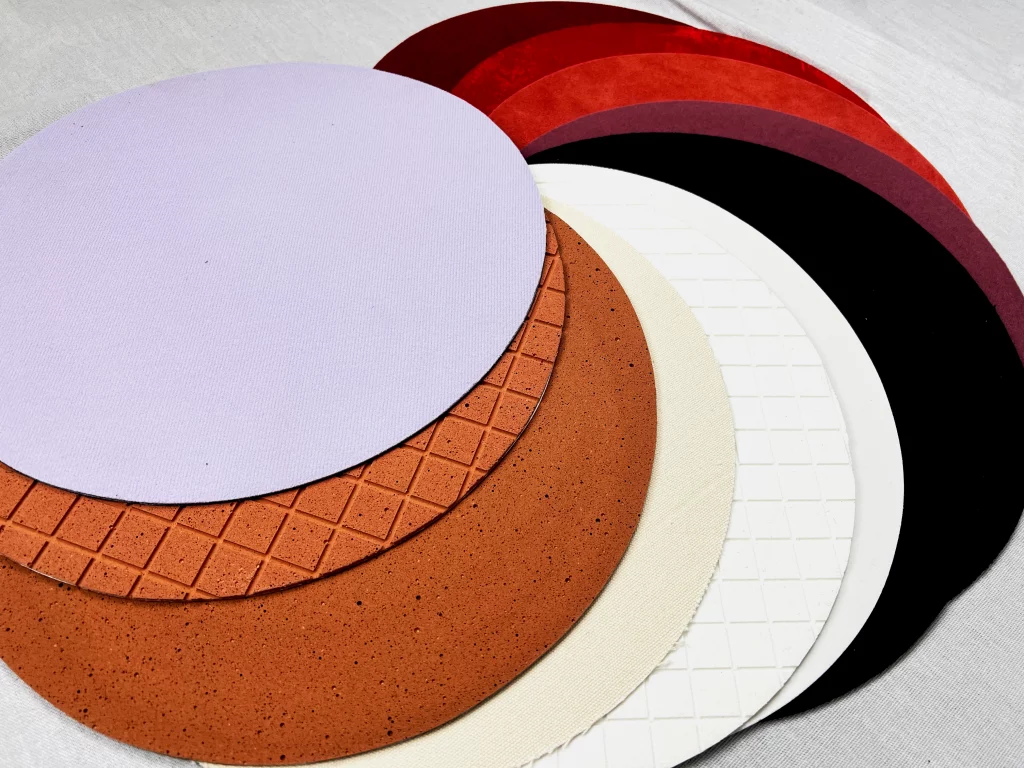

︎ Polishing cloths and polishing wheels: Choose different hardness and softness of polishing cloths and wheels according to the mold material and requirements.

Polishing pad / Grinding pad >>>> Coming soon, contact sales staff for more details~

- Materials:

- With abrasives: cerium oxide polishing pads, zirconia polishing pads

- Without abrasives: silk, leather, polyurethane (black velvet), woven fabric, fleece, porous, hard cloth, soft cloth, etc.

Polishing wheel / Grinding wheel >>> Grinding and polishing peripheral consumables

- Materials:

- With abrasives: woven wheels, rubber grinding wheels, PVA grinding wheels, abrasive cloth wheels, resin grinding wheels

- Without abrasives: cloth wheels, sisal wheels, wool wheels, etc.

︎ Fine grain powder: Used to remove fine scratches and defects, providing a uniform surface texture.

Polishing powder >>> Polishing powder

Polishing powder: Includes aluminum oxide powder, cerium oxide polishing powder, silicon carbide polishing powder, diamond polishing powder, garnet powder, etc.

Conclusion

The repair of metal polishing defects is not only about restoring surface quality, but also ensuring that the molds can operate smoothly during production, thereby improving product quality and production efficiency. As personnel responsible for repairs, mastering the basic knowledge and techniques of polishing defect repair, and selecting the appropriate materials and tools, will help reduce production costs and enhance the factory’s competitiveness.

Regular training of technical staff, updating equipment, and optimizing process flows are key to continuously improving polishing quality. Through these measures, mold factories can better handle various challenges in production, ensuring that every product meets high-quality standards.

Action

- Does the current measurement of surface roughness meet your expected target? >>> Comparison Table of Grinding and Polishing with Surface Roughness

- Do the workpieces need to be compatible with each other?

- How to solve >>> Six mold polishing techniques: How many do you know?

- Implement >>> polishing abrasives, polishing equipment, polishing tools

- Review

We offer customized adjustments to the grinding process, tailored to meet processing requirements for maximum efficiency.

After reading the content, if you still don’t know how to select the most suitable option,

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have any topics you want to learn more about or if you find it difficult to explain over the phone, feel free to message us on Facebook.

Honway Facebook: https://www.facebook.com/honwaygroup