Table of Contents

Introduction

“Surface roughness” refers to how rough or smooth a surface is, and it is closely related to our daily lives. From production to manufacturing, mastering its measurement is crucial. Before diving into the topic, it’s important to understand that “not everything should be pursued for extreme smoothness; instead, the focus should be on achieving ‘appropriate roughness’ based on specific needs.”

You may ask why?

Because when we set a very low Ra value during processing, the required manpower, time, and costs can multiply significantly.

Therefore, choosing an appropriate level of roughness is a more efficient option in the current processing choices.

In manufacturing and processing products, surface quality is extremely important. Surface roughness and smoothness are two key indicators, but they differ in meaning and measurement methods.

Surface roughness: Refers to the tiny bumps and irregularities on a surface that affect the product’s function and durability, usually expressed in values such as Ra.

Smoothness: Describes how smooth a surface is and its ability to reflect light. The smoother the surface, the higher the gloss, making the product look more polished and shiny.

Roughness affects Smoothness: The rougher the surface, the lower the gloss, as light is scattered rather than reflected. Conversely, lower roughness results in a smoother surface, enhancing gloss and giving the product a more premium appearance.

To achieve the expected smoothness, specialized polishing materials are typically used. These materials effectively remove minor surface irregularities, making the surface smoother and thus improving gloss. Understanding roughness, gloss, and how to use polishing materials to improve surface quality is crucial for producing high-quality products. Whether to enhance performance or appearance, controlling surface roughness and achieving appropriate gloss are essential steps.

Comparison Chart of Surface Roughness

| Surface Condition | Reference Length | Caption | Surface Roughness | ||

| RA | RY(Rmax) | RZ | |||

| Superfine Surface | 0.08 | A surface obtained through superfine processing methods, with a smooth finish resembling a mirror. | 0.010 a | 0.040 s | 0.040 z |

| 0.012 a | 0.050 s | 0.050 z | |||

| 0.016 a | 0.063 s | 0.063 z | |||

| 0.020 a | 0.080 s | 0.080 z | |||

| 0.25 | 0.020 a | 0.080 s | 0.080 z | ||

| 0.025 a | 0.100 s | 0.100 z | |||

| 0.032 a | 0.125 s | 0.125 z | |||

| 0.040 a | 0.16 s | 0.16 z | |||

| 0.050 a | 0.20 s | 0.20 z | |||

| 0.063 a | 0.25 s | 0.25 z | |||

| 0.080 a | 0.32 s | 0.32 z | |||

| 0.100 a | 0.40 s | 0.40 Z | |||

| Fine-Cut Surface | 0.8 | A surface obtained through one or more precise cutting methods such as turning, milling, grinding, boring, lapping, honing, polishing, or scraping. The cutting marks are nearly imperceptible to touch or sight. | 2.5 a | 10.0 s | 10.0 z |

| 3.2 a | 12.5 s | 12.5 z | |||

| 4.0 a | 16 s | 16 z | |||

| 5.0 a | 20 s | 20 z | |||

| 6.3 a | 25 s | 25 z | |||

| 8.0 a | 32 s | 32 z | |||

| 10.0 a | 40 s | 40 z | |||

| Medium-Cut Surface | 2.5 | A surface obtained through one or more moderate cutting processes such as turning, milling, planing, grinding, drilling, boring, honing, or filing. It feels smooth to the touch, but slight cutting marks can still be visually distinguished. | 2.5 a | 10.0 s | 10.0 z |

| 3.2 a | 12.5 s | 12.5 z | |||

| 4.0 a | 16 s | 16 z | |||

| 5.0 a | 20 s | 20 z | |||

| 6.3 a | 25 s | 25 z | |||

| 8.0 a | 32 s | 32 z | |||

| 10.0 a | 40 s | 40 z | |||

| Rough-Cut Surface | 8 | A surface obtained through one or more rough cutting processes such as turning, milling, planing, grinding, drilling, boring, or filing. The residual cutting marks are clearly distinguishable by touch and sight. | 12.5 a | 50 s | 50 z |

| 16.0 a | 63 s | 63 z | |||

| 20 a | 80 s | 80 z | |||

| 25 a | 100 s | 100 z | |||

| 32 a | 125 s | 125 z | |||

| 40 a | 160 s | 160 z | |||

| 50 a | 200 s | 200 z | |||

| 63 a | 250 s | 250 z | |||

| 80 a | 320 s | 320 z | |||

| As-Cast Surface | 25 or above | A surface obtained through non-cutting processes such as casting, forging, die-casting, rolling, flame cutting, or arc cutting. The original surface may be left as-is or slightly refined, but the raw material’s scale may still be retained. | 100 a | 400 s | 400 z |

| 125 a | 500 s | 500 z | |||

Surface Roughness and Smoothness Comparison Table

| Grade Code | RA | RZ |

| △14 | ≤0.01 um | ≤0.05 um |

| △13 | >0.01~0.02 um | >0.05~0.1 um |

| △12 | >0.02-0.04 um | >0.1 ~0.2 um |

| △11 | >0.04-0.08 um | >0.2 ~0.4 um |

| △10 | >0.08~0.16 um | >0.4-0.8 um |

| △9 | >0.16~0.32 um | >0.8~1.6 um |

| △8 | >0.32 ~0.63 um | >1.6-3.2 um |

| △7 | >0.63~1.25 um | >3.2~6.3 um |

| △6 | >1.25~2.5 um | >6.3~10 um |

| △5 | >2.5~5 um | >10~20 um |

| △4 | >5~10 um | >20~40 um |

| △3 | >10~20 um | >40~80 um |

| △2 | >20-40 um | >80~160 um |

| △1 | >40~80 um | >160~320 um |

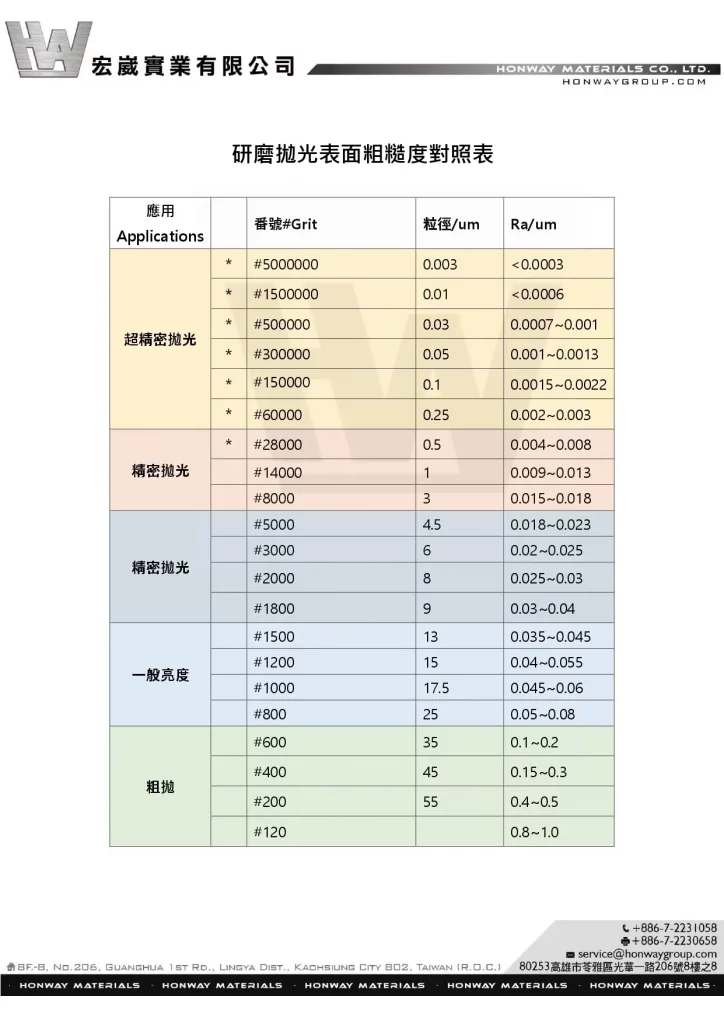

Comparison Chart of Grinding Polishing and Surface Roughness

Action

- Has the currently measured surface roughness met your expected target?

- Solution >>> Six mold polishing techniques: How many do you know?

- Implement >>> polishing abrasives, polishing equipment, polishing tools

- Review

After reading the content, if you still don’t know how to select the most suitable option,

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have a subject that you want to know or a phone call that is not clear, you are welcome to send a private message to Facebook~~

Honway Facebook: https://www.facebook.com/honwaygroup

You may be interested in…

[wpb-random-posts]