In most cases, mechanical polishing is more eco-friendly than chemical polishing due to: 1. The polishing techniques used, 2. The selection of polishing materials, 3. The handling of waste, 4. Energy consumption.

Modern manufacturing emphasizes not just individual stages but also the overall environmental impact of processing techniques.

To make high-carbon polishing processes more sustainable and energy-efficient, it may be worth considering integrating mechanical polishing into existing procedures.

Polishing: Is a process that reduces the surface roughness of an object using either mechanical methods or chemical agents. Polishing techniques are widely used in the precision machinery and optics industries. The surface of a polished workpiece becomes smooth and exhibits good reflective properties.

Table of Contents

What is Mechanical Polishing?

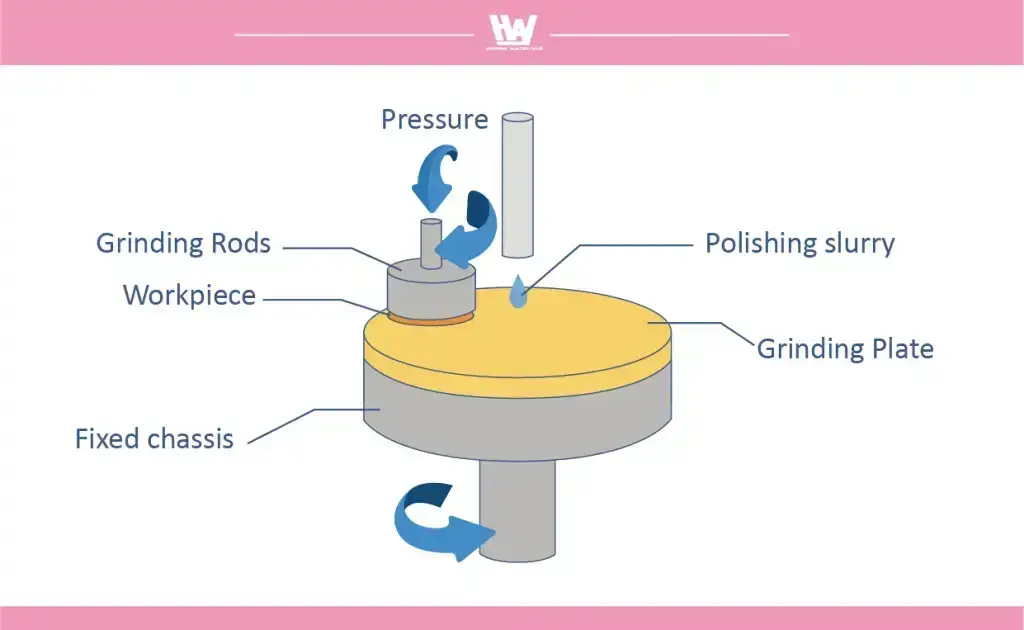

Mechanical polishing involves using plastic deformation or cutting to remove protrusions from a metal surface to achieve smoothness.

Common polishing tools include sandpaper, grinding discs, and polishing pads. When a high-quality surface finish is required, ultra-precision polishing techniques are often employed, with the assistance of metallographic grinders and other equipment.

Ultra-precision polishing involves pressing specialized grinding tools against the workpiece surface and using a polishing liquid containing abrasives at high-speed rotation. This technique can achieve surface roughness of less than Ra0.008μm. The process further enhances surface quality and achieves extremely high smoothness.

Advantages

- Enhances the surface gloss and texture of materials.

- Provides a smooth foundation for subsequent processes, such as coating or plating.

Disadvantages

- Requires high technical skill, especially to achieve a high-quality finish.

- May result in uneven polishing for complex-shaped workpieces.

- The process can produce dust or noise, requiring environmental and safety measures.

Ultra-Precision Polishing

Ultra-precision polishing is designed to improve material surface quality and is particularly suitable for applications requiring high precision.

Below are common ultra-precision polishing methods:

※ Techniques involving chemical properties are marked in bold.

- Chemical Mechanical Polishing (CMP)

- Magnetorheological Finishing (MRF)

- Ion Beam Polishing

- Ultrasonic Polishing

- Electrochemical Polishing (ECP)

- Laser Polishing

What is Chemical Polishing?

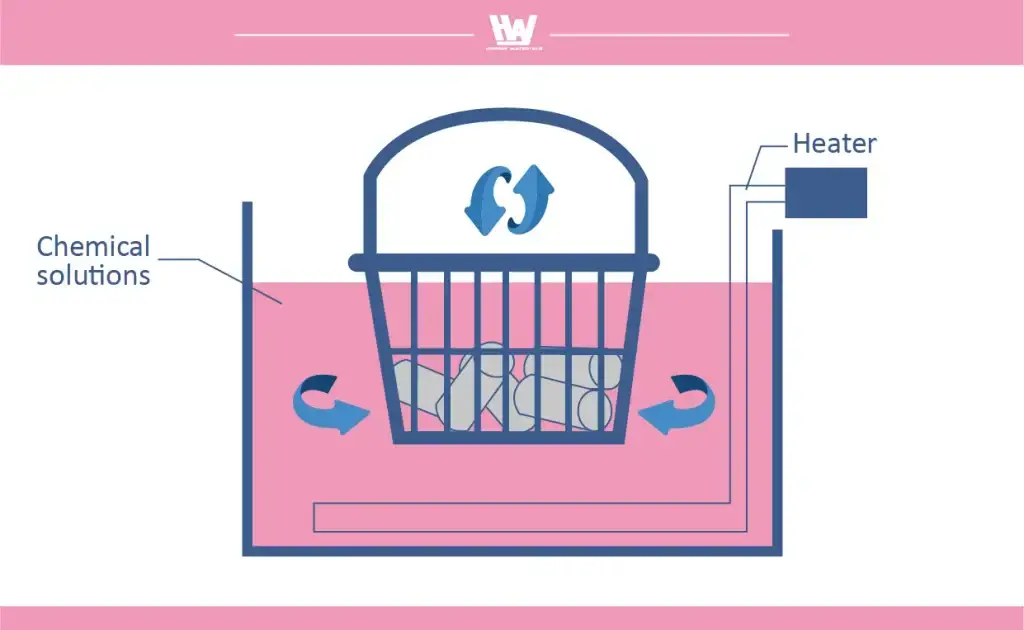

Chemical polishing is a process that uses chemical reactions to remove microscopic protrusions on a material’s surface, achieving a smooth and flat finish.

Unlike mechanical polishing, it does not rely on external mechanical forces. Instead, the workpiece is immersed in a specific chemical solution, which selectively dissolves the material’s surface to create a polished effect.

The resulting surface roughness is typically in the range of 10μm.

Advantages

- Capable of polishing complex-shaped workpieces.

- Can process multiple workpieces simultaneously, suitable for mass production.

- Simple operation that does not require specialized mechanical equipment, only appropriate chemical solutions.

Disadvantages

- Chemical solutions used may be corrosive or toxic, requiring careful handling and waste management.

- Not all materials are suitable for chemical polishing, as some may react unstably with specific solutions.

- While it improves surface smoothness, it is less precise in controlling dimensional tolerances compared to mechanical polishing.

- May result in uneven brightness.

(Further reading: Six mold polishing techniques: How many do you know?)

Why is mechanical Polishing more Environmentally Friendly than Chemical Polishing?

Mechanical polishing is generally considered more eco-friendly than chemical polishing due to its lower environmental and human impact, material usage, and waste management requirements.

| Mechanical Polishing | Chemical Polishing | |

| Materials used | Mechanical polishing primarily uses physical tools such as grinding discs or polishing pads. Typically requires minimal polishing liquids or water, resulting in a lower environmental impact. | Relies on strong acids, bases, or other corrosive chemicals such as nitric acid and hydrofluoric acid. Can be toxic and pose risks to water and soil, necessitating rigorous waste treatment. |

| Process heating requirements | Mechanical polishing is often performed at room temperature, requiring minimal external heating, which significantly reduces energy consumption. | Sometimes requires high-temperature conditions to accelerate reactions, such as heated acid or alkaline solutions. Leading to higher energy demands, especially in industrial-scale operations. |

| Waste disposal | Primarily consists of solid materials such as metal powders or grinding residues Easier to recycle or dispose of with minimal long-term environmental impact | May contain heavy metals, acidic or basic substances, or other toxic compounds, improper handling can lead to severe pollution. Waste recycle or neutralization processes are often energy-intensive. |

| Energy consumption | Typically relies on the operation of machinery, with relatively controlled electricity demand and no additional energy consumption associated with chemical production. | Require production, packaging, storage, and transportation. These steps generate additional carbon emissions, making the energy demand and carbon footprint of chemical polishing generally higher than that of mechanical polishing. |

| Storage of materials | Tools such as sandpaper, grinding discs, polishing pads, and polishing liquids do not require special storage conditions, resulting in relatively low energy consumption and carbon emissions. | Chemical products require specialized storage facilities to ensure stability and safety, such as temperature-controlled environments and corrosion-resistant storage tanks. These storage requirements consume energy and continuously emit greenhouse gases. |

| Health effects | Processing process may produce dust or noise. However, with adequate ventilation and protective measures, the health impact on operators is relatively low. | The toxicity and corrosiveness of chemical products can pose health risks, such as causing respiratory, skin, or eye irritation. Workplaces using chemical polishing require stricter safety precautions and protective measures. |

Recommended Polishing Tools

Nano diamond polishing solution / Grinding solution / Suspension >>>Polishiing solution

- Best suited for: mechanical operation

- State: liquid (oil-based/water-based/alcohol-based)

- Polishing can be performed using a double-sided grinding machine, chemical mechanical polishing (CMP), or metallographic grinding.

- ※ Since the abrasive is in a free state, it is suitable for large-scale polishing.

- ※ If the surface of the workpiece is still rough, choose a polishing liquid with larger particles.

Alumina / Cerium oxide polishing solution / Grinding solution / Suspension >>> Polishing solution

- Best suited for: mechanical operation

- Status: Liquid

- Scope of application: Generally used after diamond compound

- ※ Possesses the ability of repairing polishing marks on the workpiece.

- ※ Cerium oxide is recommended to be used with tools at low speed.

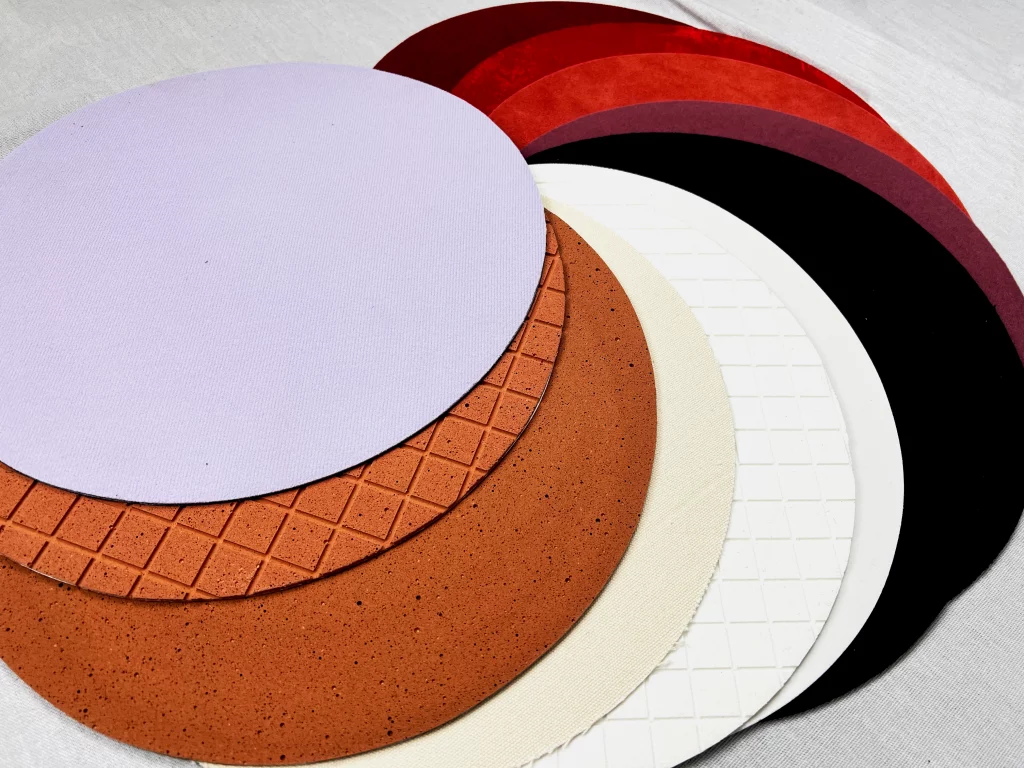

Polishing pad / Grinding pad >>>> Metallographic consumables

- Materials:

- Contains abrasive: Cerium oxide polishing pad, Diamond resin grinding disc, Electroplate diamond grinding disc

- Without abrasives: silk, leather, polyurethane (black velvet), woven fabric, fleece, porous, hard cloth, soft cloth, etc.

Conclusion

Mechanical polishing is more environmentally friendly than chemical polishing because it does not use corrosive or toxic chemical solutions, reducing harm to both the environment and workers. The waste generated from mechanical polishing is mainly solid abrasives or dust, which are relatively easier to recycle and dispose of, posing lower risks of water and soil pollution. This makes mechanical polishing a preferred choice in manufacturing processes that prioritize sustainability and environmental protection.

Action

- Learn what ESG is at once>>>What is ESG? What Benefit can ESG Bring to Companies? How to Implement ESG?

- Mandatory Carbon Inventory for Large Enterprises>>>What is Carbon Footprint Verification? Understanding the 5 Steps for Verification to Grasp the Future of Carbon Reduction

- Taiwan policy>>Master Global Issue at Once: Net Zero Emissions and Carbon Neutrality

- Whether are you the target of carbon footprint verification>>Which Enterprises Need Carbon Footprint Verification? What is the Future Outlook?

- Evaluate whether the current manufacturing processes meet carbon reduction objectives.

- Assess if the existing polishing processes could be replaced with more carbon-efficient alternatives.

- How to implement

- Implement testing and review

Honway specializes in physical polishing, ultra-hard abrasives, and rare-earth materials, striving to provide polishing solutions with reduced environmental impact. If you have related needs or would like to learn more, please feel free to contact us! Let’s work together toward a sustainable future.

Customized Grinding Solutions: We offer tailored adjustments to our grinding processes, allowing us to meet specific processing needs for maximum efficiency.

After reading the content, if you still don’t know how to select the most suitable option,

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have a subject that you want to know or a phone call that is not clear, you are welcome to send a private message to Facebook~~

Honway Facebook: https://www.facebook.com/honwaygroup