Introduction

Abrasive classification method

There are two main types: 1) superhard abrasives vs. regular abrasives, and 2) wheels that can grind iron vs. those that cannot.

The structural difference between superhard abrasive wheels and regular abrasive wheels

|  | |

| Construction | superhard wheels usually have a metal core (base), with abrasive material bonded to the outer layer | Regular wheels are made entirely of abrasive material |

| Usable area | Only the abrasive layer can be ground | The whole wheel to be used for grinding |

| Abrasive price | High | Low |

The bonding method of superhard abrasives:

1. Resinoid 2. Metal 3. Electroplated 4. Vitrified

The wear rate of abrasives.

3. Electroplated < 1. Resinoid < 4. Vitrified < 2. Metal

The impact of the bonding agent on chip removal efficiency

3. Electroplated > 4. Vitrified > 1. Resinoid > 2. Metal

Table of Contents

Q1. How electroplated wheels are made

Electroplated grinding wheels are produced by electroplating abrasive grains onto a metal core.

Advantages: The versatility of shapes, as any shape that can be formed from the metal core can have abrasive grains electroplated onto it.

Disadvantages: Only a thin layer of abrasive is applied, so if there is significant grain shedding, the wheel may need to be re-plated or replaced.

Q2. The current status of the grinding wheel

| Picture | Caption |

| New wheels have complete and evenly distributed abrasive grains. |

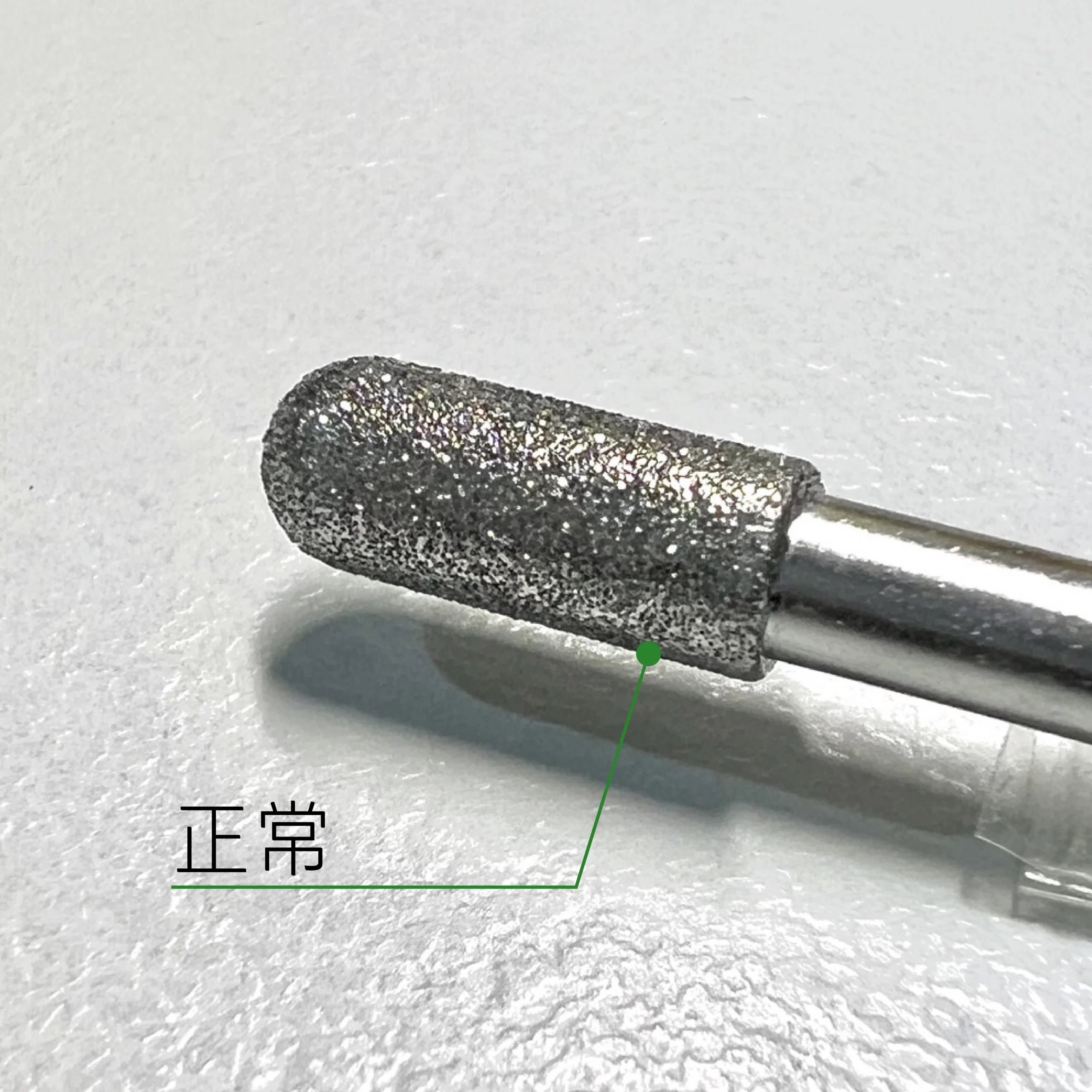

| Normally worn The appearance of a normally worn grinding wheel does not differ significantly from a new one, though the surface may appear less shiny due to grinding. However, this does not affect its performance. Normally worn wheels wear down more slowly than the workpiece being ground and self-sharpen by shedding dulled abrasive grains. |

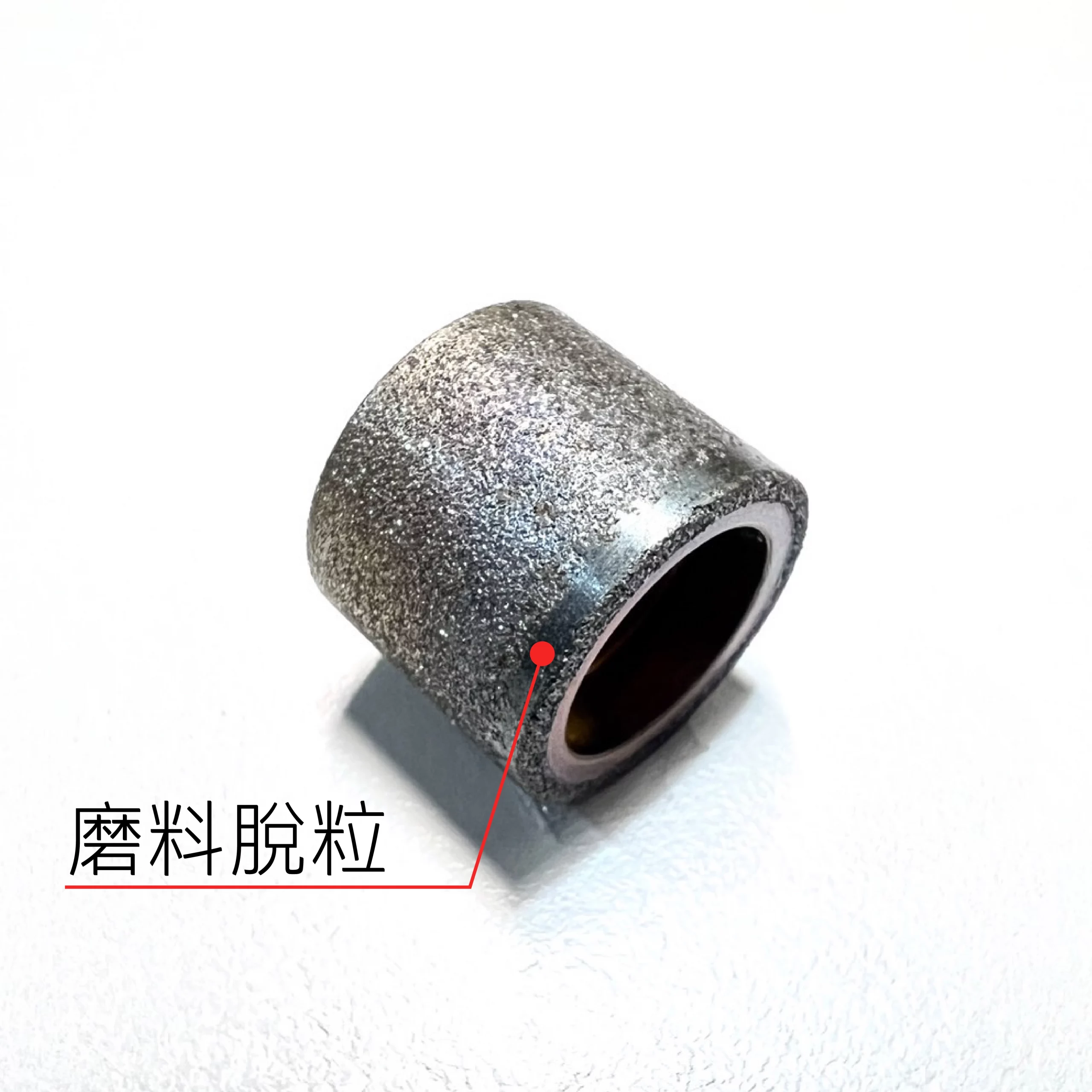

| Severe grain shedding ● Grinding issues Causes scratches, burns on the workpiece or mold, increases repair costs, and lowers efficiency. ● Causes 1. Process issues: Incomplete electroplating process, leading to weak abrasive bonding. 2. Steel core issues: Poor adhesion due to steel core materials. 3. Complex shapes:Complex shapes causing incomplete adhesion of abrasive grains. 4. Improper usage or workpiece factors. ● Solutions Process issues: Re-electroplate to correct the process. Steel core issues: Consider changing the base metal or using another bonding agent. If the issue persists, consider using finer grit for re-electroplating or adopting a different grinding method. |

| Chip clogging ● Grinding issues Chip clogging increases grinding resistance as well as reduces efficiency, , and may cause the workpiece vibrates, lead to fine surface damage and vibration marks. ● Causes 1. Grinding softer materials 2. Grinding produced thermal energy: Poor heat dissipation during grinding causing workpiece expansion, increased cutting depth, and molten chips adhering to the surface, which can cause scratches. 3. Uneven abrasive grains in size and shape: The shape of the abrasive is not fixed or the size is uneven, which may cause chips to get stuck during grinding. (When screening abrasive particles, you can imagine it like a mesh sieve: particles that remain on the same sieve size are grouped together, which explains the variance in particle size. ) When screening abrasive particles, you can imagine it like a mesh sieve: particles that remain on the same sieve size are grouped together, which explains the variance in particle size. ● Solutions If chips are large, try manually clearing them. Additionally, try reduce contact area or lower cutting depth. |

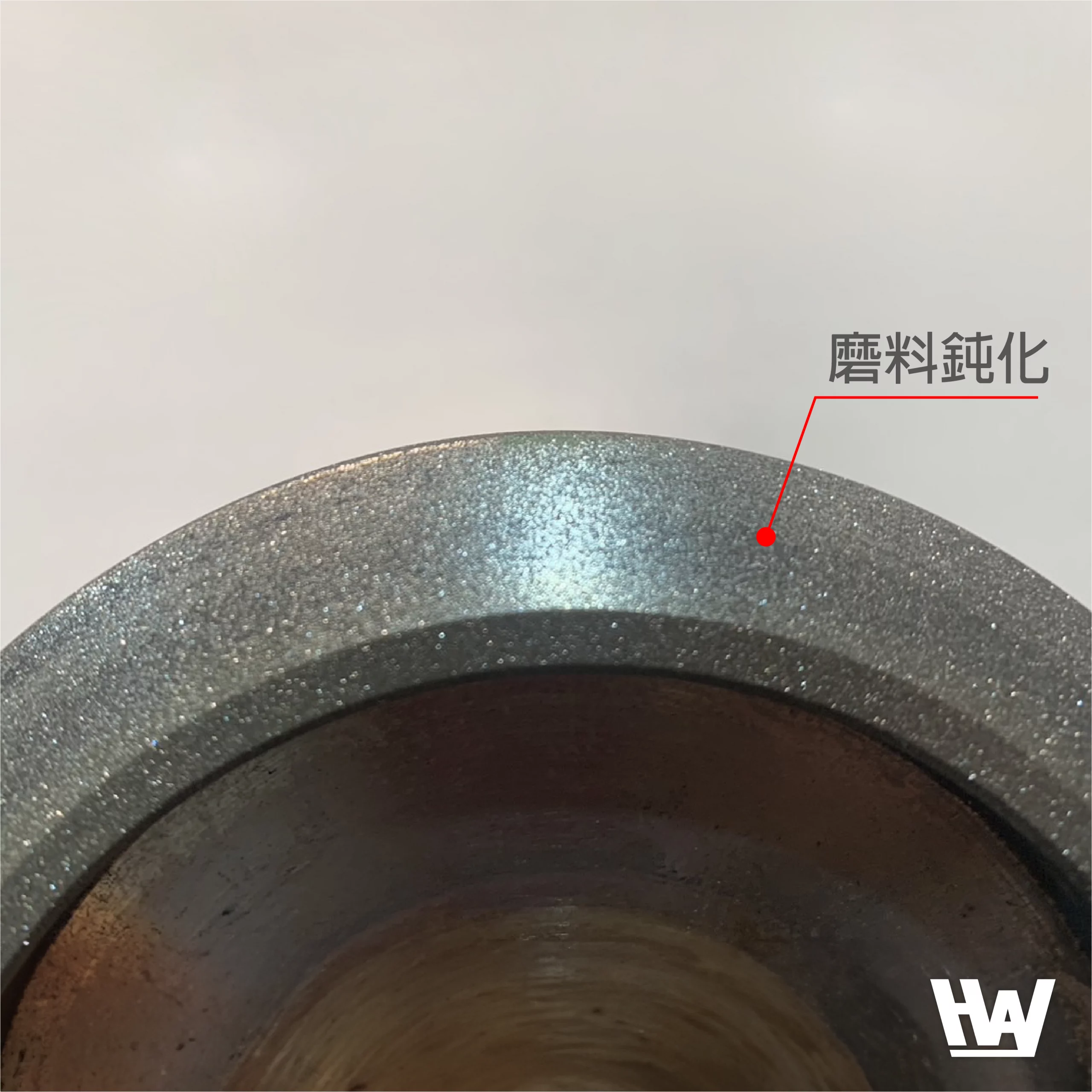

| Abrasive dulling ● Cause Cutting edges become dull after prolonged grinding. ● Grinding issues Lower cutting force: Increased processing time. Increased resistance and heat: Risk of burning or scratching the workpiece. ● Solution Consider re-ordering the wheel or preserving the substrate and re-electroplating it. (Slight color unevenness on the grinding wheel, as seen in the image, can also affect surface flatness during grinding, so it is recommended to replace the wheel.) |

Q3. Can the #150 electroplated grinding wheel be changed to #800?

Yes it can. Upon receiving the customer’s steel core, Honway will first strip the old abrasive from it before re-electroplating with a fresh layer.

Q4. What information is required when ordering a custom grinding wheel?

- Please provide us with the dimensions and specifications of the grinding wheel. We will confirm the details and provide you with a quote. Production will begin only after you approve the quote.

- If you’d like to retain the steel core and re-electroplate, feel free to contact us and send the steel core over for us to draft and process.

Q5. How to choose between diamond/CBN wheels if switching from a regular grinding wheel?

Feel free to reach out to us to discuss further, as we need to understand your current process stage and the material you are grinding to make accurate recommendations.

Conclusion

The flatness of the grinding wheel surface and the temperature during processing have a significant impact on the workpiece. Using a poor-quality grinding wheel can potentially increase the repair costs of the original polishing process instead of reducing them.

If issues arise with the workpiece, it’s better to pause the operation and inspect the grinding wheel’s surface, which might help improve the process more quickly. The feedback compiled above is based on common issues our customers have experienced when seeking solutions. We hope this can help with initial assessments. If issues persist, feel free to contact us, and we’ll work with you to find a solution.

We believe that in every newly developed machining process, repeated testing to find the fastest and most optimal path is essential, both for our customers and for us. If you’re looking for a partner who shares this commitment, we’d be happy to discuss further with you.

Action

- Is the current grinding wheel wear normally

- Does the current process meet your expected production standards

- How to solve >>> Six mold polishing techniques: How many do you know?

- Implement >>> Diamond and CBN grinding wheel, Polishing abrasive, Polishing equipment, Polishing tool

- Review

We offer customized adjustments to the grinding process, tailored to meet processing requirements for maximum efficiency.

After reading the content, if you still don’t know how to select the most suitable option,

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have a subject that you want to know or a phone call that is not clear, you are welcome to send a private message to Facebook~~

Honway Facebook: https://www.facebook.com/honwaygroup

Regular grinding wheel image sources:

Graibeard,https://commons.wikimedia.org/wiki/File:GrindingCupWheelPA46JV.jpg