What is thermal spraying?

Thermal spray technology is the heating of “raw materials” either electrically or chemically. Thermal spraying technology is a method of using a heat source to heat the spray material to a molten or semi-molten state, and spraying and depositing it onto the pre-treated substrate surface at a certain speed to form a coating. A special working surface is made on the surface of an ordinary material to achieve the following functions: corrosion resistance, wear resistance, wear resistance, high temperature resistance, oxidation resistance, heat insulation, insulation, conductivity, microwave radiation protection, etc. The main applications include: long-term corrosion protection, mechanical repair and advanced manufacturing technology, mold making and repair, and manufacturing special functional coatings. Various thermal spraying processing methods are widely used in the hardening of workpiece surfaces. The superhard tools of Honway Materials are suitable for polishing the inside and outside of workpieces before grinding and coating of complex surfaces.

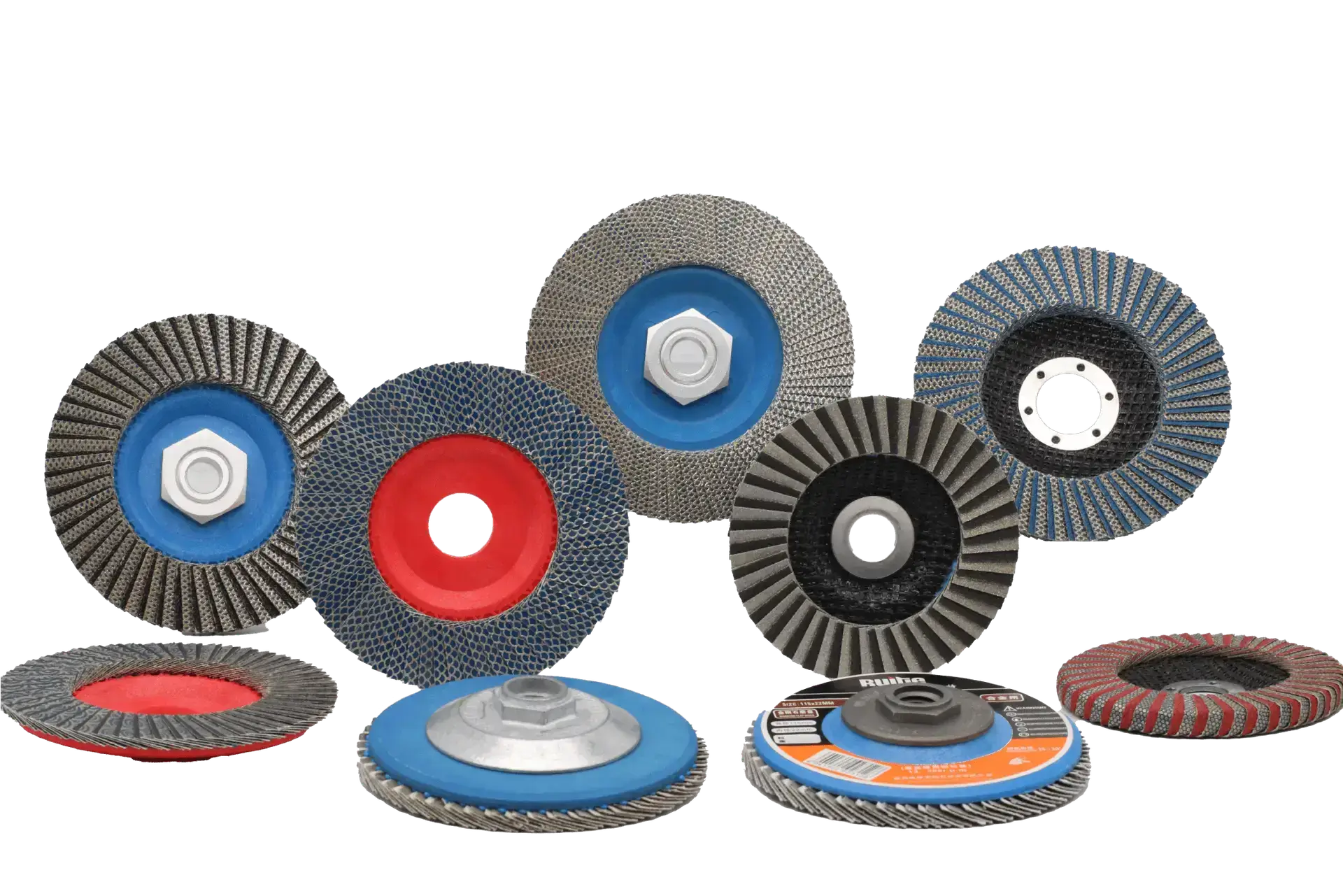

Diamond/cBN Cylindrical Grinding Wheel

Diameter: 25 – 1100 mm / 1 – 43 inch

Abrasive ring width: 5 – 50 mm

Diamond/cBN Hand Rubber Block

Granularity: #40 – #600

Size: 4 inches, 4.5 inches, 5 inches

*Other sizes available on request

Width: 5 mm – 30 mm

Length: 150 mm – 5000 mm

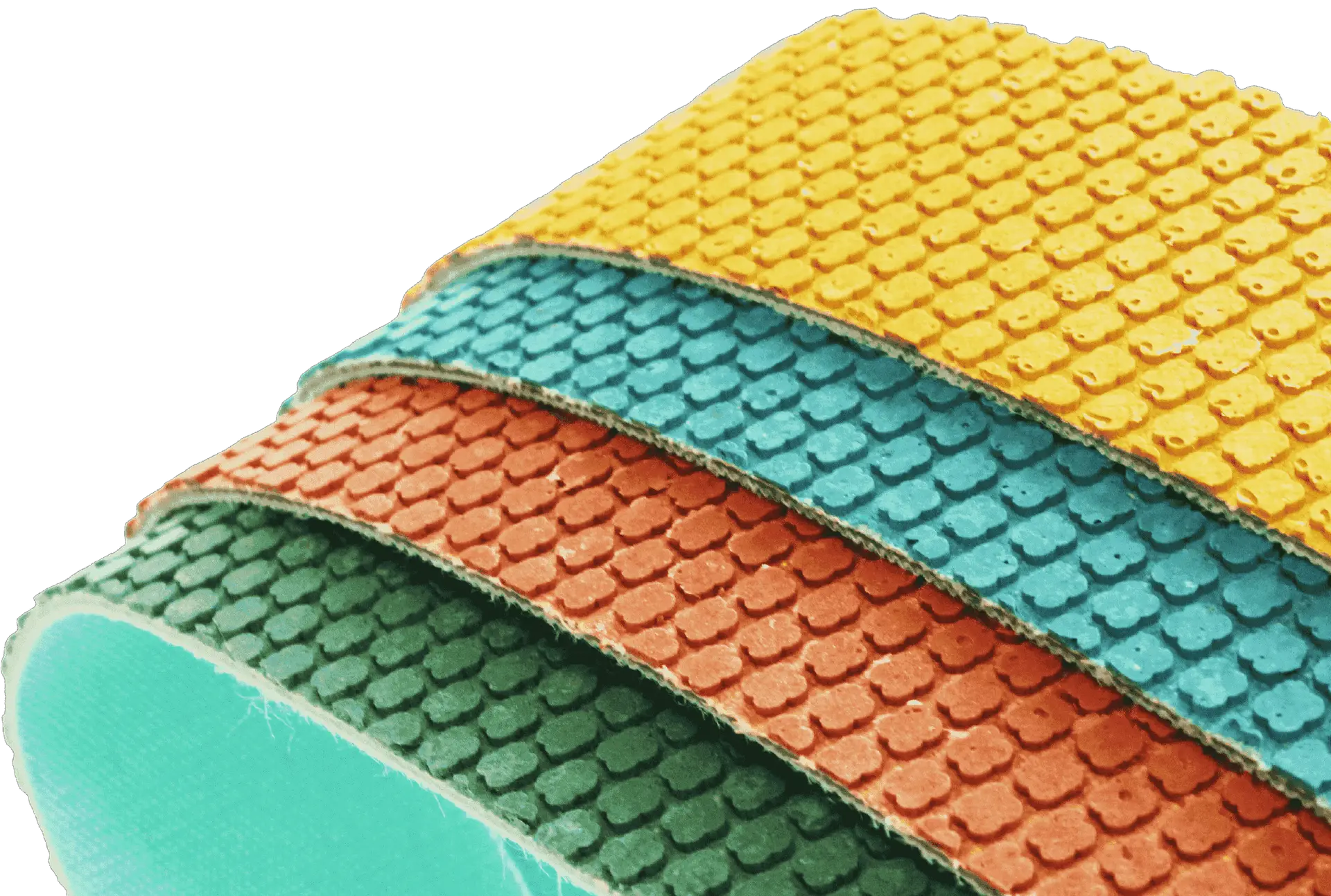

Diamond/cBN Abrasive Belt

Granularity: #40 – #5000

Binder: Electroplating / Resin

Electrostatic Sanding Diamond Film Sanding Belt

Coarse grinding: 125 μm, 70 μm

Fine grinding: 60 μm, 45 μm, 30 μm, 15 μm, 94 μm