HonWay Materials -Leading Brand of Diamond Grinding and Polishing Tools in Taiwan

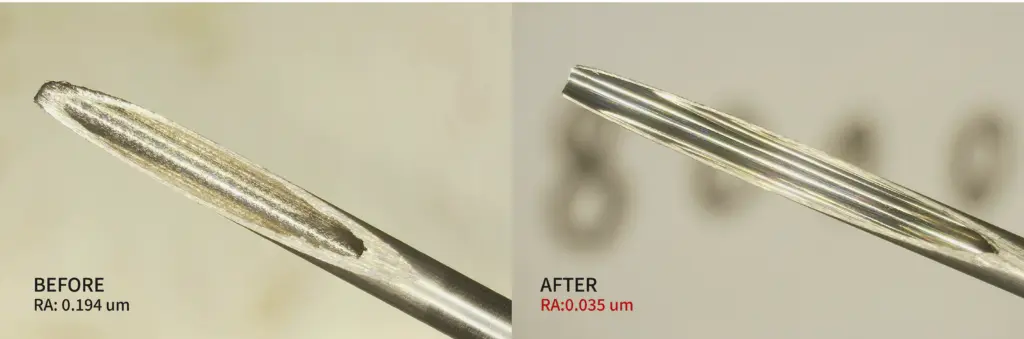

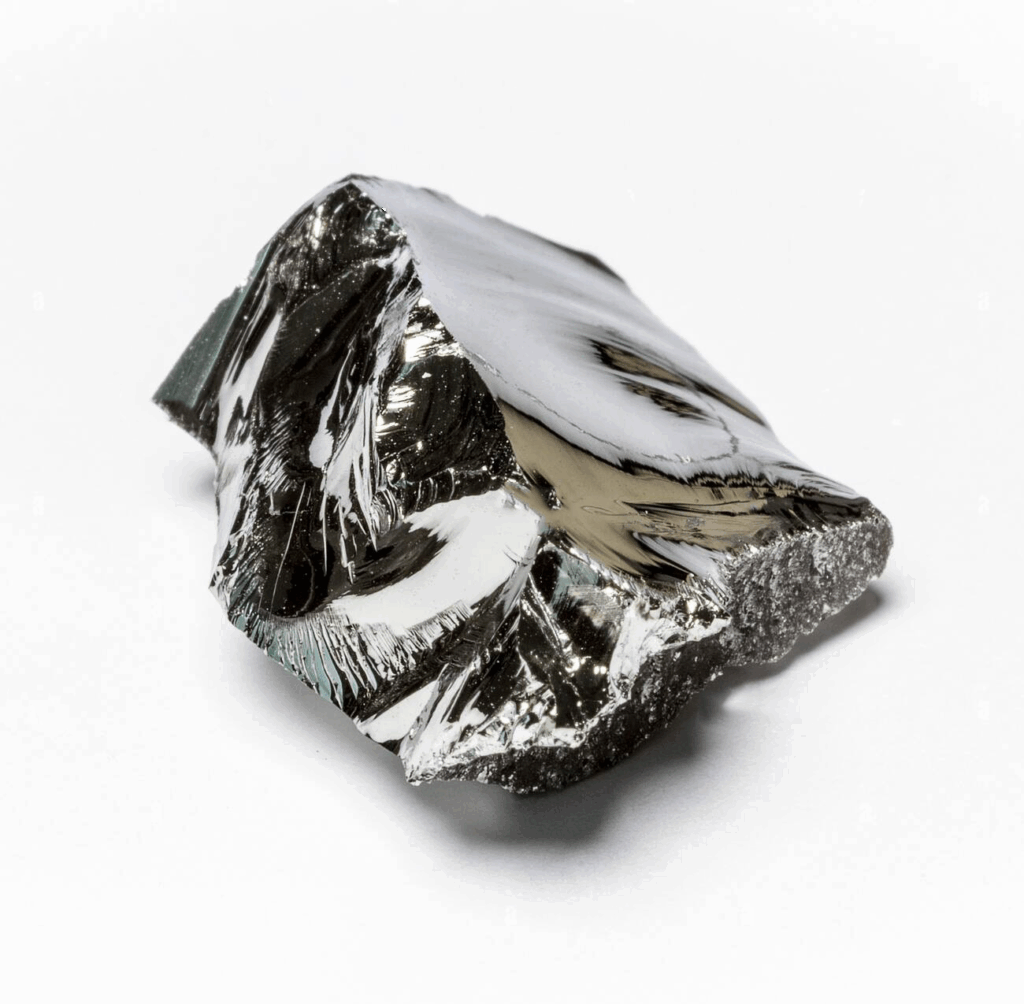

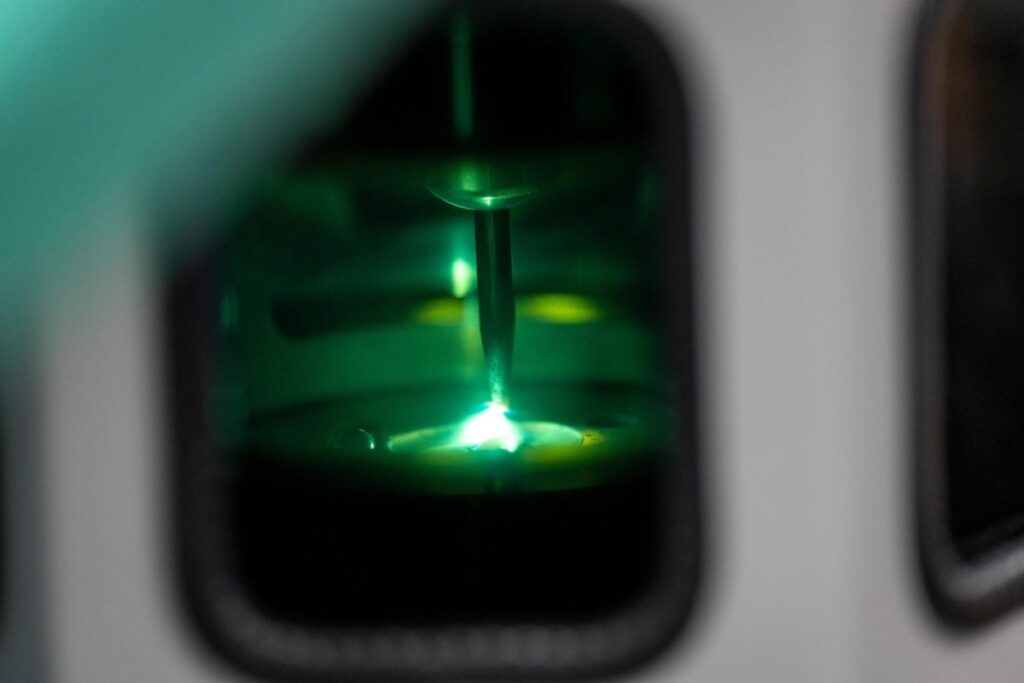

Diamond paste, diamond slurry, diamond powder, precision polishing

HonWay Materials -Leading Brand of Diamond Grinding and Polishing Tools in Taiwan

Diamond paste, diamond slurry, diamond powder, precision polishing

HonWay Materials -Leading Brand of Diamond Grinding and Polishing Tools in Taiwan

Diamond paste, diamond slurry, diamond powder, precision polishing

HonWay Materials -Leading Brand of Diamond Grinding and Polishing Tools in Taiwan

Diamond paste, diamond slurry, diamond powder, precision polishing