“Surface roughness” refers to how rough or smooth a surface is, and it is closely related to our daily lives. From production to manufacturing, mastering its measurement is crucial. Before diving into the topic, it’s important to understand that “not everything should be pursued for extreme smoothness; instead, the focus should be on achieving ‘appropriate roughness’ based on specific needs.”

You may ask why?

Because when we set a very low Ra value during processing, the required manpower, time, and costs can multiply significantly.

Therefore, choosing an appropriate level of roughness is a more efficient option in the current processing choices.

目錄

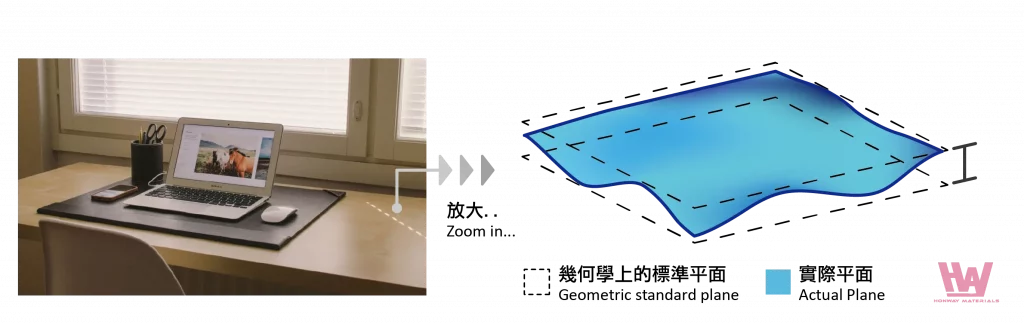

Before we start understanding what “surface roughness” is, we first need to understand what “surface flatness” is. This will help us correctly convey our meaning when discussing or describing these concepts in depth with others.

Surface Flatness

Flatness refers to “the degree to which a surface deviates from a geometrically correct plane.”

In simple terms, it means “how flat the surface is.” The flatter a surface, the higher its flatness, and vice versa.

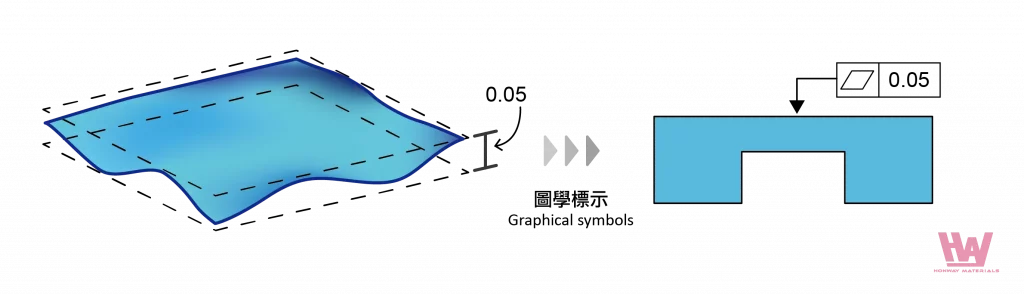

In technical drawings, the tolerance for flatness is represented by the fixed distance between the highest peak and the lowest valley of the standard plane.

The closer this interval is to 0, the closer it is to a geometrically correct plane.

Surface flatness is extremely important in engineering and manufacturing, particularly for parts that require fitting or contact. For example, the flatness of mechanical parts affects their functionality and durability, so the surface flatness requirements are usually strictly controlled during manufacturing.

Surface Roughness

Abbreviated as Roughness

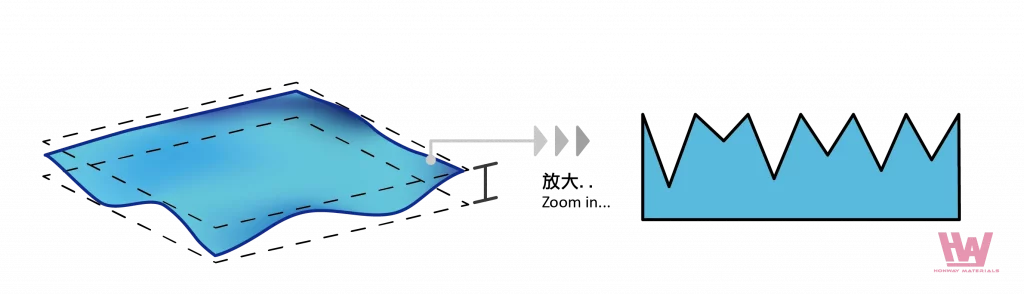

What is surface roughness? Simply put, it refers to whether a surface is “rough or smooth.”

Imagine touching a piece of paper versus touching sandpaper. The surface of the sandpaper feels much rougher.

In science or engineering, roughness is typically used to describe the degree of small-scale irregularities or undulations on a surface. If a surface is very smooth, we say it has low roughness; if it is very rough, then the roughness is high.

What are the effects of surface roughness on the workpiece?

- Airtightness: For some non-moving sealed surfaces, if the roughness is too high, it may lead to poor sealing performance; for some moving surfaces, if the surface is too smooth, it may cause leakage and wear. Such as water pipe joints, sealed jars.

- Mating performance: When objects are in sliding motion, if the surface is too rough, it may require more force to move, which leads to increased energy consumption and wear of the objects, such as in ball bearings and screws.

- Rigidity: When two surfaces are in contact, the increase in unit area pressure (concentrated stress) makes the material more prone to deflection deformation under external force, leading to insufficient contact area between the peaks. Examples include wind turbines and electric screwdrivers.

- Molds:The ease and completeness of mold release during the molding process are influenced by the surface roughness of the mold.

- Adhesion: Appropriate roughness is necessary for adhesion, welding, and assembly of objects.

- Appearance and tactile feel: Surface roughness affects the gloss of car paint and the tactile sensation of matte surfaces.

- Corrosion resistance and insulation: High roughness can lead to liquid retention on the surface, which may promote corrosion. For objects frequently in contact with such liquids, a lower roughness is recommended.

- Electromagnetic properties: Excessive roughness can cause electromagnetic retention, affecting transmission and potentially causing heating.

- Optical refraction: Variations in roughness can lead to scattering, refraction, or diffraction.

- Noise: High-speed machinery with rough surfaces can generate vibration and noise during operation.

Summary

- Flatness and surface roughness are two different concepts. Flatness is viewed from a macroscopic perspective, while surface roughness is viewed microscopically, determining whether an object is rough or smooth.

- A surface can have high flatness (close to zero deviation) yet still be rough. However, a very rough surface is not necessarily flat.

Consider a frosted chessboard like above. Is it flat? Yes, it is flat. But is it smooth? Likely not.

- We know that flatness has an absolute value, which is approaching zero, the correct geometric plane, but surface roughness does not; there is only an “appropriate” level of roughness.

This is why, when discussing the effects of roughness, we haven’t explicitly stated whether smoothness or roughness is preferable—it depends on the intended application and desired outcome.

Action

- Understand the goal you wish to achieve

- Workpiece surface roughness requirements >>> Terminology and definitions of surface roughness

- How to solve? >>> Six mold polishing techniques: How many do you know?

- Choose the right polishing solution >>> Polishing abrasives, polishing equipment, polishing tools

- Implement

- Review

After reading the content, if you still don’t know how to select the most suitable option,

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have any topics you want to learn more about or if you find it difficult to explain over the phone, feel free to message us on Facebook~

Honway Facebook: https://www.facebook.com/honwaygroup

您可能感興趣的文章…

[wpb-random-posts]