Semiconductor

A semiconductor is a material with electrical conductivity that falls between that of an insulator and a conductor. Within a specific temperature range, as the temperature increases, the concentration of charge carriers rises, leading to increased conductivity and decreased resistivity. At absolute zero, it behaves as an insulator. Semiconductors play a crucial role in both technological and economic fields. Semiconductor devices can control current transmission through structural and material design, forming the basis for circuits that process various signals, which is why semiconductors are widely used in modern electronics.

Solve cutting and grinding problems

The use of suitable diamond blades and grinding wheels can solve the problems of cutting and grinding semiconductor materials and devices.

Solution

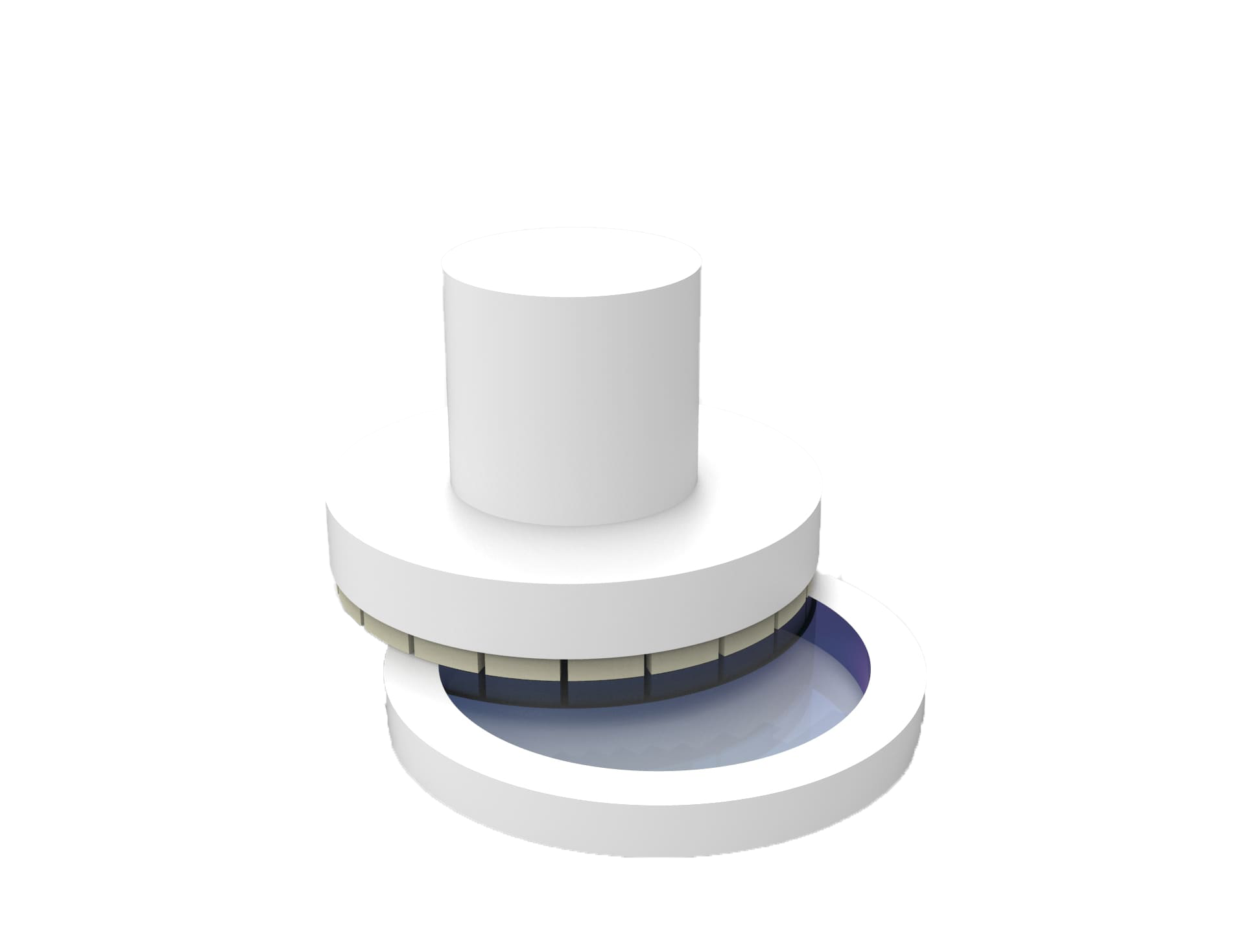

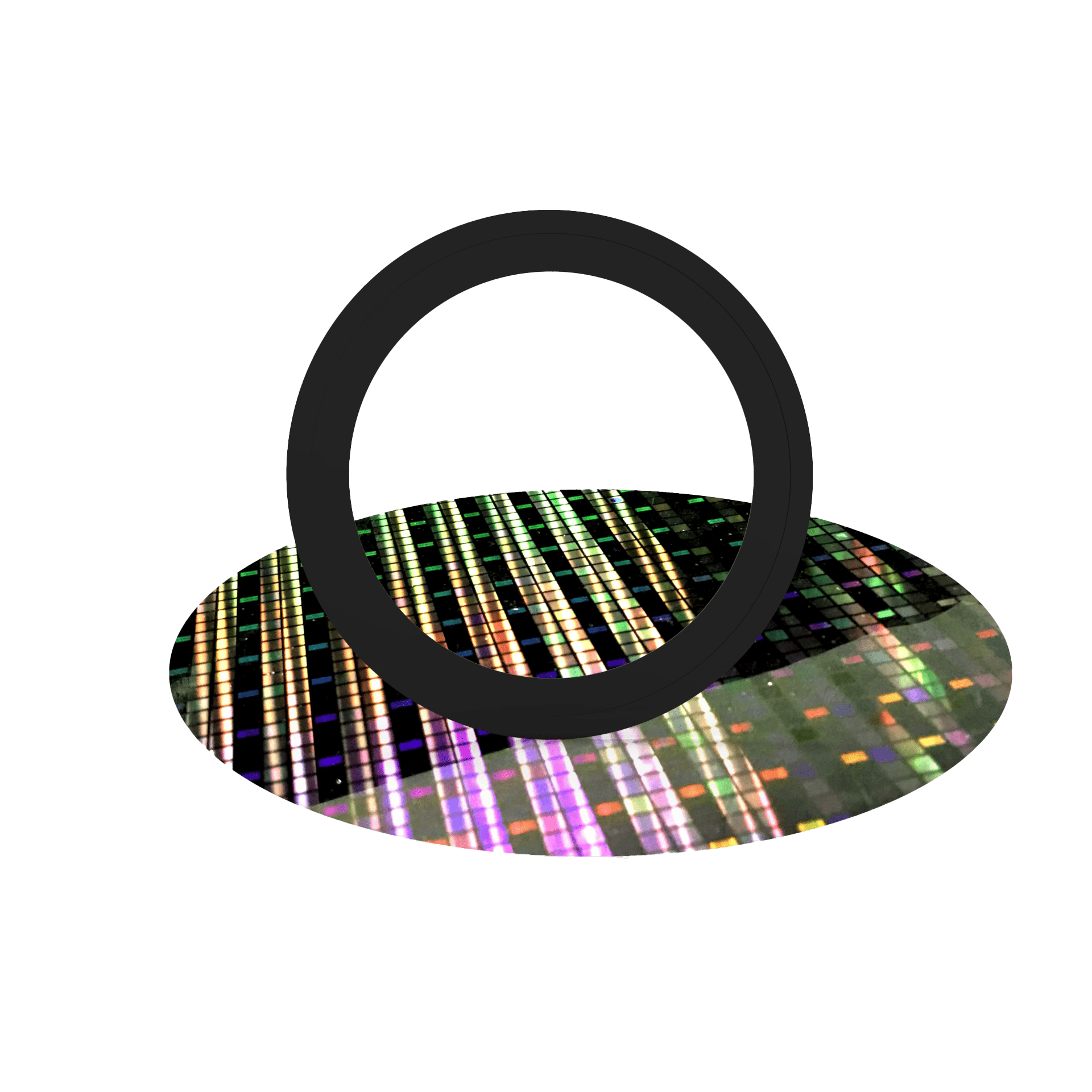

Wafer

Wafer is an abbreviation for semiconductor wafer, which is a thin slice of cylindrical semiconductor crystal used as a carrier substrate in the process of integrated circuits and in the manufacture of solar cells; it is called a wafer because of its round shape. Silicon wafers are the most common type of wafers, with Gallium Nitride wafers, Silicon Carbide wafers, etc. The most common type of wafers produced are single crystal silicon wafers. The larger the wafer, the more integrated circuits can be produced on the same wafer, which can reduce costs; however, the higher requirements for material technology and production technology, such as uniformity and other issues, have led to a shift away from the pursuit of larger wafers in recent years, and in some cases, manufacturers will stay in the old, mature process due to factors such as cost and yield. It is generally believed that the larger the diameter of a silicon wafer, the better the technology of the fab, and in the process of producing wafers, the yield rate is a very important condition.

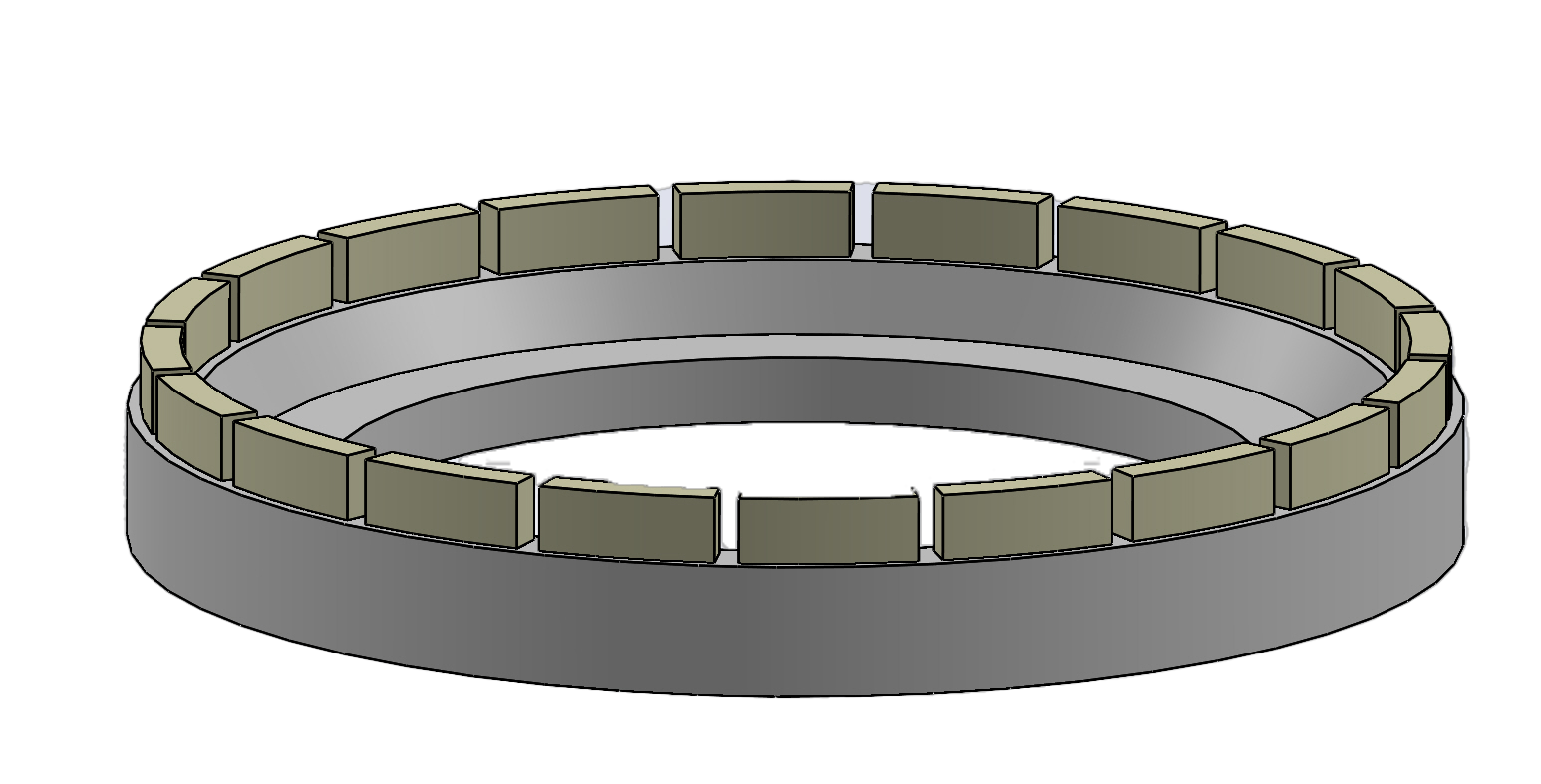

Hub Type Dicing Blades

A hub type dicing blade designed to reduce blade breakage and meandering issues during slant cutting.

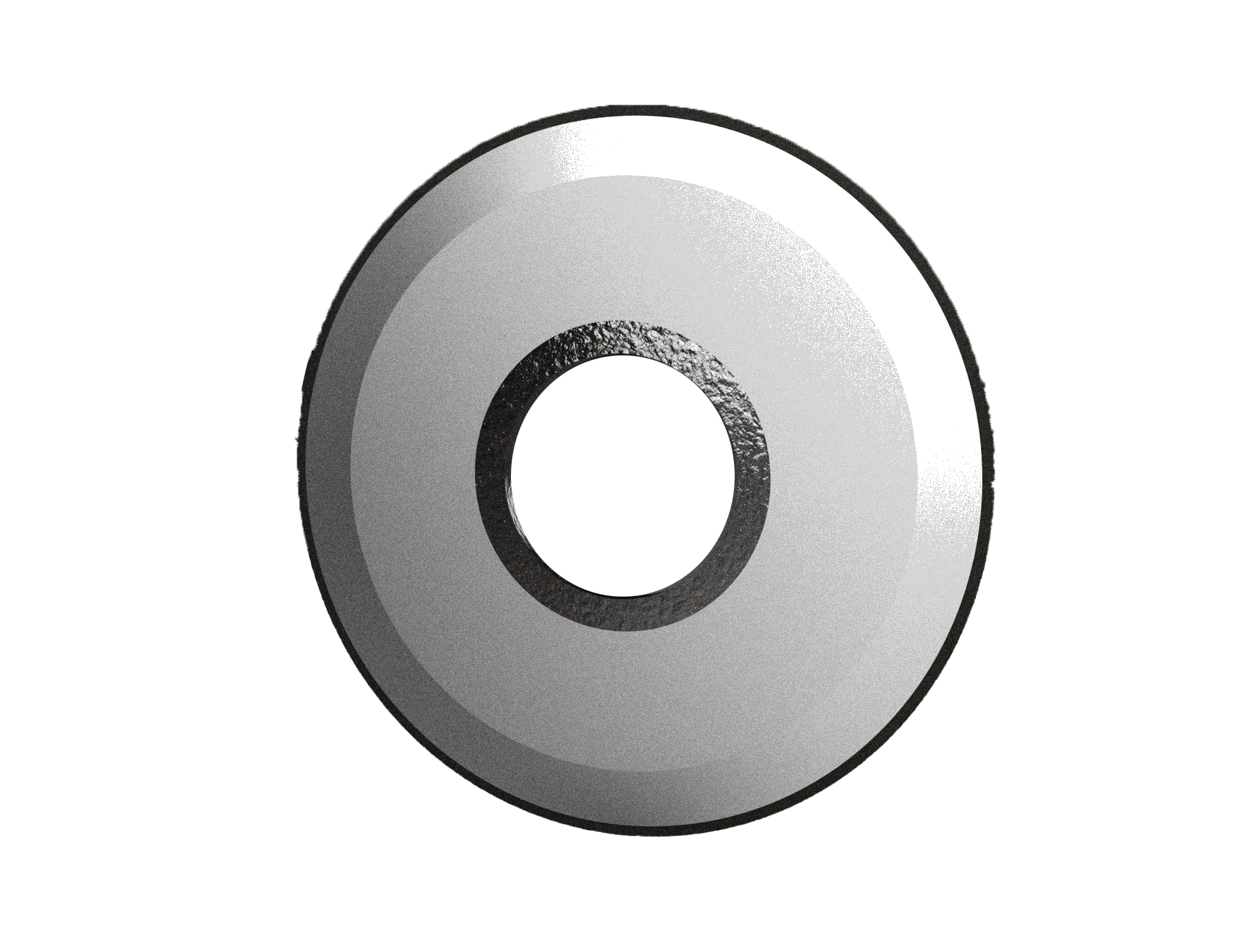

Dicing Blades (Hubless)

- Resin Binder Blades for Semiconductor Packaging

- Metal Binder Blades that maintain rigidity and improve cutting ability.