Currently, semiconductor manufacturing faces increasingly complex technical challenges, especially in critical processes such as ohmic contact modeling, where traditional artificial intelligence methods are gradually reaching their limits. However, a new study from Australia’s national science agency CSIRO has for the first time applied Quantum Machine Learning (QML) to the analysis of real semiconductor manufacturing process data, demonstrating superior performance over classical methods. This breakthrough not only proves the potential of quantum technology in small-sample, high-dimensional environments but also opens up new possibilities for chip design and process optimization. This article will take you deep into this world-first research achievement and how it might rewrite the future development path of semiconductors.

Table of Contents

Semiconductor Modeling Faces Bottlenecks, Quantum Computing Enters the Fray

In the highly precise and increasingly complex processes of the semiconductor industry, how to effectively model becomes a major challenge. Especially for critical steps like Ohmic Contact formation, which involve multiple process parameters and non-linear relationships, traditional artificial intelligence and machine learning methods are gradually showing their limitations.

Recently, a research team from Australia’s national science agency CSIRO, in collaboration with international partners from China and Hong Kong, for the first time validated a new model centered on Quantum Machine Learning (QML), specifically designed to solve modeling challenges in semiconductor manufacturing, and successfully applied it to experimental data analysis. This research achievement is hailed as a world first and has been published in the journal Advanced Science.

QKAR: A Quantum Regression Architecture Designed for Small Samples

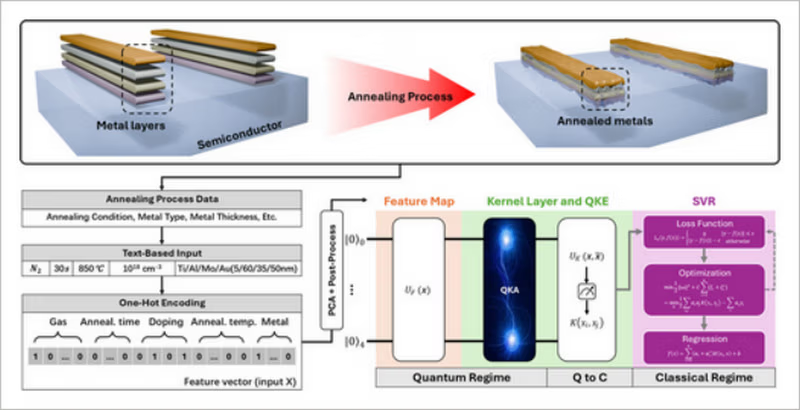

This research focused on manufacturing samples of GaN HEMT (Gallium Nitride High Electron Mobility Transistor). The research team developed an innovative model called the “Quantum Kernel Alignment Regressor (QKAR)” using only 159 experimental data points. This model integrates Pauli-Z feature mapping with a trainable quantum kernel layer, enabling it to extract deep patterns from extremely small datasets while maintaining high precision.

QKAR’s performance surpassed that of seven traditional CML (Classical Machine Learning) regressors, demonstrating significant advantages across various regression error metrics (such as MAE, MSE, RMSE). Particularly in terms of Mean Absolute Error (MAE), QKAR achieved 0.338 Ω·mm, showcasing excellent accuracy and generalization capabilities.

Addressing Data Scarcity and Non-Linear Challenges: Quantum Advantage Emerges

In the past, although classical machine learning models were widely used in manufacturing modeling, they often faced problems such as overfitting and insufficient generalization when dealing with small samples, high-dimensional parameters, and complex non-linear scenarios. Quantum machine learning, on the other hand, can leverage its unique kernel properties to capture highly interactive relationships between complex parameters and exhibit stronger fault tolerance and data adaptability.

As co-author Zeheng Wang stated: “The semiconductor industry is increasingly challenged by both data scarcity and process complexity. Our research shows that well-designed quantum models can identify underlying patterns that classical models cannot grasp.”

Combining Quantum and Classical Technologies: A Crucial Step in Experimental Validation

A major highlight of this research is that although the adopted model architecture runs on a simulator, it is compatible with current NISQ (Noisy Intermediate-Scale Quantum) hardware, suggesting potential for direct deployment in the future. The team further manufactured new GaN devices, providing physical validation to support the model’s predictions, marking an important step towards the practical application of quantum machine learning models.

In addition, the research also established a unified PCA (Principal Component Analysis) preprocessing pipeline, ensuring a fair comparison between models and demonstrating the rigor and scientific nature of the research design.

Semiconductor Modeling Enters a New Paradigm? Quantum Technology’s Potential is Limitless

With the development of quantum computing technology, its applications are gradually expanding from chemical simulation, cryptography, and material research to manufacturing engineering, with semiconductor processes becoming another frontier application area. The successful validation of the QKAR model represents quantum machine learning’s potential to become a new paradigm for future chip design and manufacturing modeling, especially in scenarios with scarce data and complex process conditions.

Researchers point out that although CML methods still have room for optimization, QML has already demonstrated its potential as an auxiliary or alternative tool. In the future, as quantum processor scale and fidelity continue to improve, these quantum models will have greater opportunities to make significant contributions in actual industrial processes.

Conclusion: Quantum Innovation from Laboratory to Fab

Semiconductors are the cornerstone of modern technology, and their manufacturing processes are a focal point of technological challenges and innovation. Research units such as Australia’s CSIRO are injecting new momentum into semiconductor manufacturing through quantum technology. The application of QML may not only improve manufacturing efficiency and reduce costs but is also expected to bring about a revolution in the entire industry, from data modeling to process optimization.

This transformation, driven by quantum machine learning, might just be the critical turning point in the chip race over the next decade.

Reference:

- Reshaping Future Chips, Quantum Machine Learning Shines Brightly

- Quantum Machine Learning Shines in Semiconductor Chip Design

- Quantum machine learning improves semiconductor manufacturing for first time

(Source of the first picture: pexels)

We offer customized adjustments to the grinding process, tailored to meet processing requirements for maximum efficiency.

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have a subject that you want to know or a phone call that is not clear, you are welcome to send a private message to Facebook~~

Honway Facebook: https://www.facebook.com/honwaygroup

You may be interested in…

[wpb-random-posts]