Resin Method Diamond and Boron Nitride Grinding Wheels

HONWAY can provide customized services.

We can make the most suitable resin diamond and CBN grinding wheels for you.

Electroforming grinding wheels listed in the table below are our standard stock.

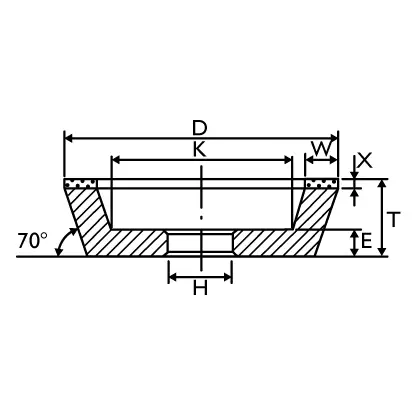

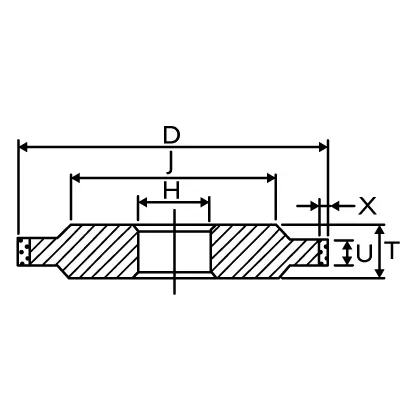

| 11C9 | Suitable for tool grinders, tungsten steel tool grinding and forming | |||||||

|---|---|---|---|---|---|---|---|---|

|

Code | D | W | X | U | T | H | Grit Size |

| RD-04815A | 100 | 8 | 1 | 5 | 40 | 20 | SDC-150* | |

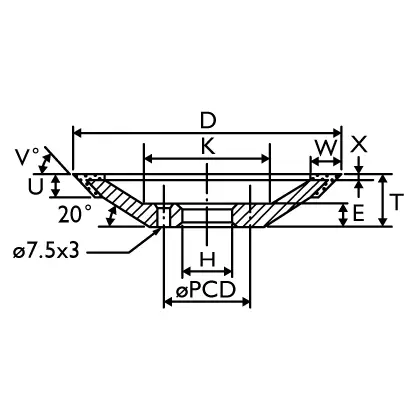

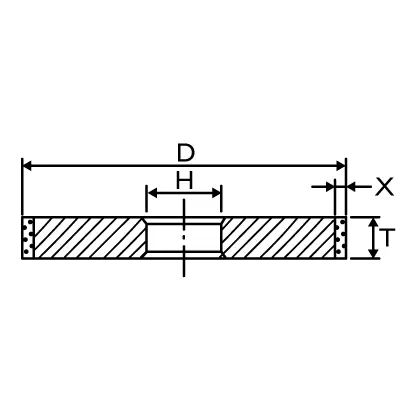

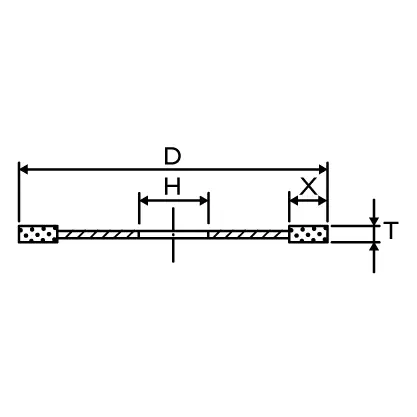

| 1A1 | Suitable for surface grinding machines, grinding tungsten carbide, ceramic (SDC) or hardened steel (BC) | |||||||

|---|---|---|---|---|---|---|---|---|

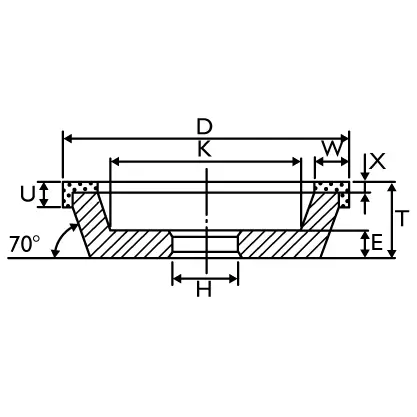

| 14A1 | Code | D | U | X | T | H | shape | Grit Size |

| RD-06033A | 150 | 3 | 3 | 10 | 31.75 | 14A1 | SDC-150* | |

| RB-06033A | 150 | 3 | 3 | 10 | 31.75 | 14A1 | BC-150* | |

| RD-06063A | 150 | 6 | 3 | 10 | 31.75 | 14A1 | SDC-150* | |

| RB-06063A | 150 | 6 | 3 | 10 | 31.75 | 14A1 | BC-150* | |

| RD-06083A | 150 | 8 | 3 | 10 | 31.75 | 14A1 | SDC-150* | |

| RD-06103A | 150 | – | 3 | 10 | 31.75 | 1A1 | SDC-150* | |

| RB-06103A | 150 | – | 3 | 10 | 31.75 | 1A1 | BC-150* | |

| RD-07063A | 175 | 6 | 3 | 10 | 31.75 | 14A1 | SDC-150* | |

| RD-07103A | 175 | – | 3 | 10 | 31.75 | 1A1 | SDC-150* | |

| RB-07103A | 175 | – | 3 | 10 | 31.75 | 1A1 | BC-150* | |

| RB-07133A | 175 | – | 3 | 13 | 31.75 | 1A1 | BC-150* | |

Description :

- “*”Standard particle size, other particle sizes please specify the order.

Any questions? Contact HonWay