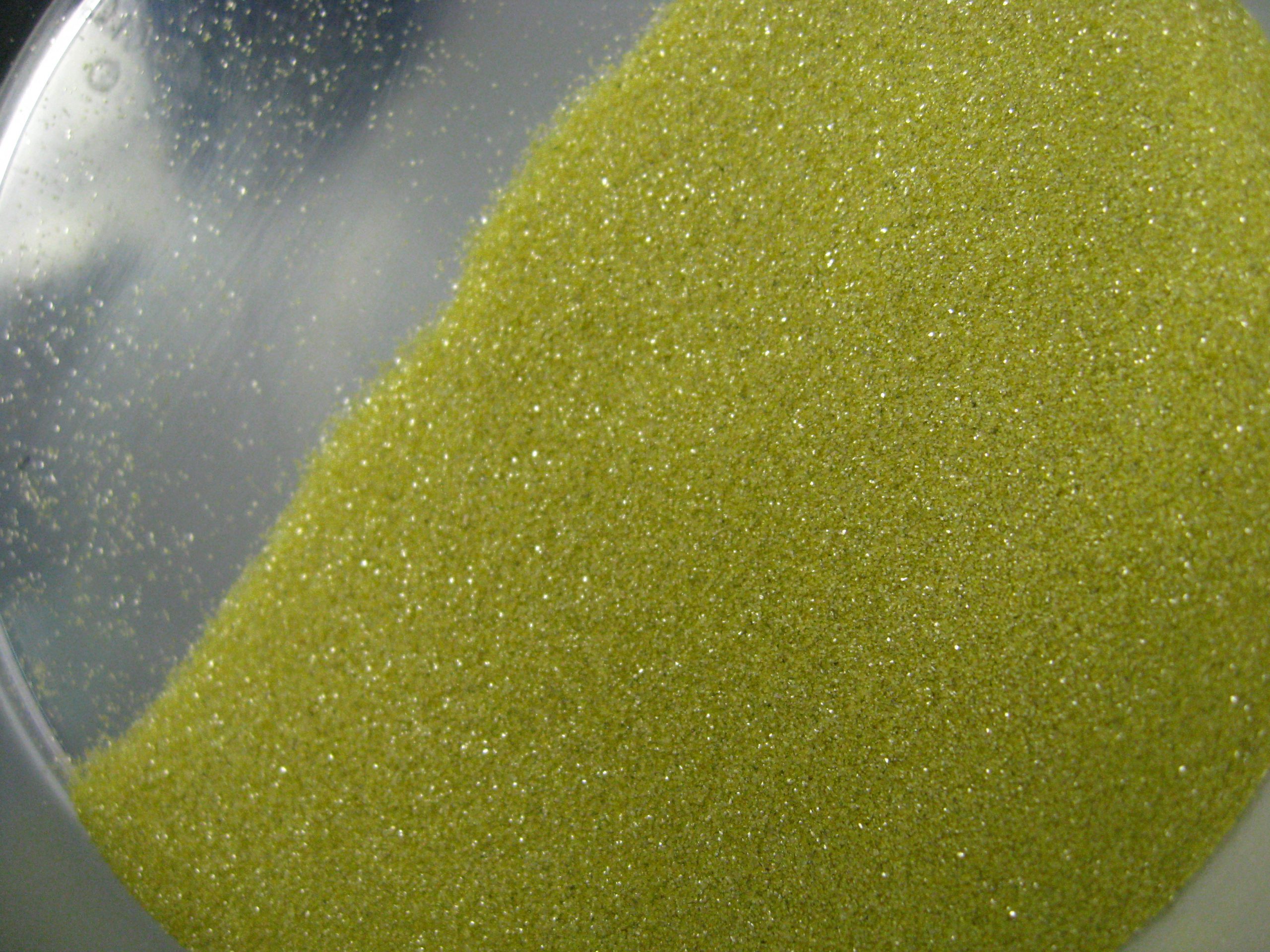

Polycrystalline diamond powder (polycrystalline etching method)

Diamond Micro Powder, also known as Diamond Powder, is one of the hardest abrasives known to date, and is used as the main grinding and polishing material for diamond, gemstone, jade, tungsten steel, ceramics, glass, machinery, geology and other industries for high gloss workpieces and related instruments and gauges.

The main uses of diamond micropowder:

1. Directly use abrasives and pastes made of micronized powders for free grinding or polishing. Widely used in the processing of metal materials and hard alloys, ceramics and optical glass and instrumental jewels.

2. Diamond powder is used in a large number of fine grinding wheels, ultra-fine grinding wheels, electroplating abrasives and so on.

3. Diamond powder with a particle size of 54-0.25 microns is the main raw material for the manufacture of polycrystalline diamond sinter or other diamond products (geology, oil drilling cutting tools and wire drawing dies, etc.).

4. Diamond micropowder is plated on the surface of certain workpieces to increase their wear resistance.

Any questions? Contact HonWay