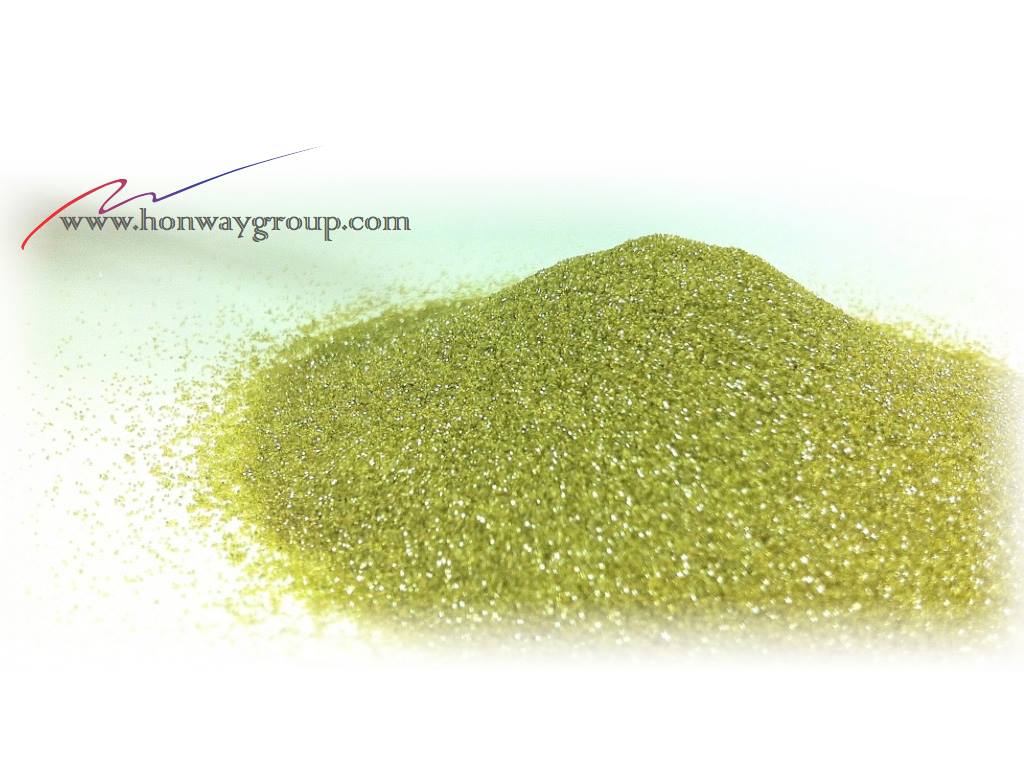

Monocrystalline Diamond Powder (High Temperature and High Pressure)

Monocrystalline Diamond Powder, Polycrystalline Diamond Powder

-

Monocrystalline Diamond Micropowder

Diamond powder is a kind of super-hard grinding and polishing material, which is produced by selecting high-quality monocrystalline synthetic diamond as raw material and going through the processes of crushing, shaping, purifying, grading and post-processing.

Monocrystalline Diamond Powder Applications

-

- Free grinding and polishing of gemstones, metals, etc.

- Manufacturing of precision grinding wheels and cutting blades

- Manufacturing of PCD for mining, petroleum, geology and cutting tools

- Manufacturing of wire drawing dies, precision soft grinding discs, etc.

- Manufacturing of electroplated diamond grinding wheels, etc.

-

Monocrystalline diamond powder:

Monocrystalline diamond micropowder is produced from high-quality synthetic monocrystalline diamonds, undergoing processes such as crushing, shaping, purification, grading, and post-treatment. It is a superhard abrasive and polishing material with high hardness, strength, toughness, thermal conductivity, and good thermal stability and impact resistance.

Monocrystalline Diamond Powder, Polycrystalline Diamond Powder -

Monocrystalline diamond powder specification:

General Specifications Unit: Micron

0-0.5 (0.25um) 0-1 (0.5um) 0-2 (1um) 1-3 (2um) 2-4 (3um) 4-6 (5um)

6-12 (8um) 8-16 (10um) 10-20 (15um) 15-25 (20um) 20-30 (25um) 20-40 (30um)

35-45 (40um) 55-65 (50um) 50-60 (55um)

※All of the above are general rules, which can be adjusted according to customer’s needs and accept customization.

Any questions? Contact HonWay