Metallographic Alumina Polishing Powder

It is mainly composed of aluminum and oxygen, and the chemical formula is Al2O3Al_2O_3 . It has a wide range of applications in many industries, especially in the fields of grinding, polishing, electronics, ceramics, manufacturing and catalysts. The characteristics and uses of alumina powder depend on its preparation method, particle size, crystal form and other factors.

Features:

- With high hardness, good mechanical properties and chemical stability, alumina polishing powder can usually provide excellent polishing results and is suitable for different types of surface polishing needs.

- It has good abrasion resistance and can maintain a stable polishing effect in many uses.

- Spherical alumina will have the function of repairing the polished surface on the workpiece, which can make the polished surface polished better, reduce the surface roughness, and obtain a brighter and cleaner surface.

- It has a low cost advantage.

- It is recommended to use it as a surface cleaner after general diamond powder.

- It is recommended to use the same grade of diamond powder as the last diamond powder or use a finer particle size.

- If you need a higher grade polishing surface, it is recommended to choose “Ultra Aluminum Powder”.

Applications:

- Use with a metallographic polishing pad.

- All kinds of metals, precision molds, sapphire, aluminum alloys, ceramics and other final polishing.

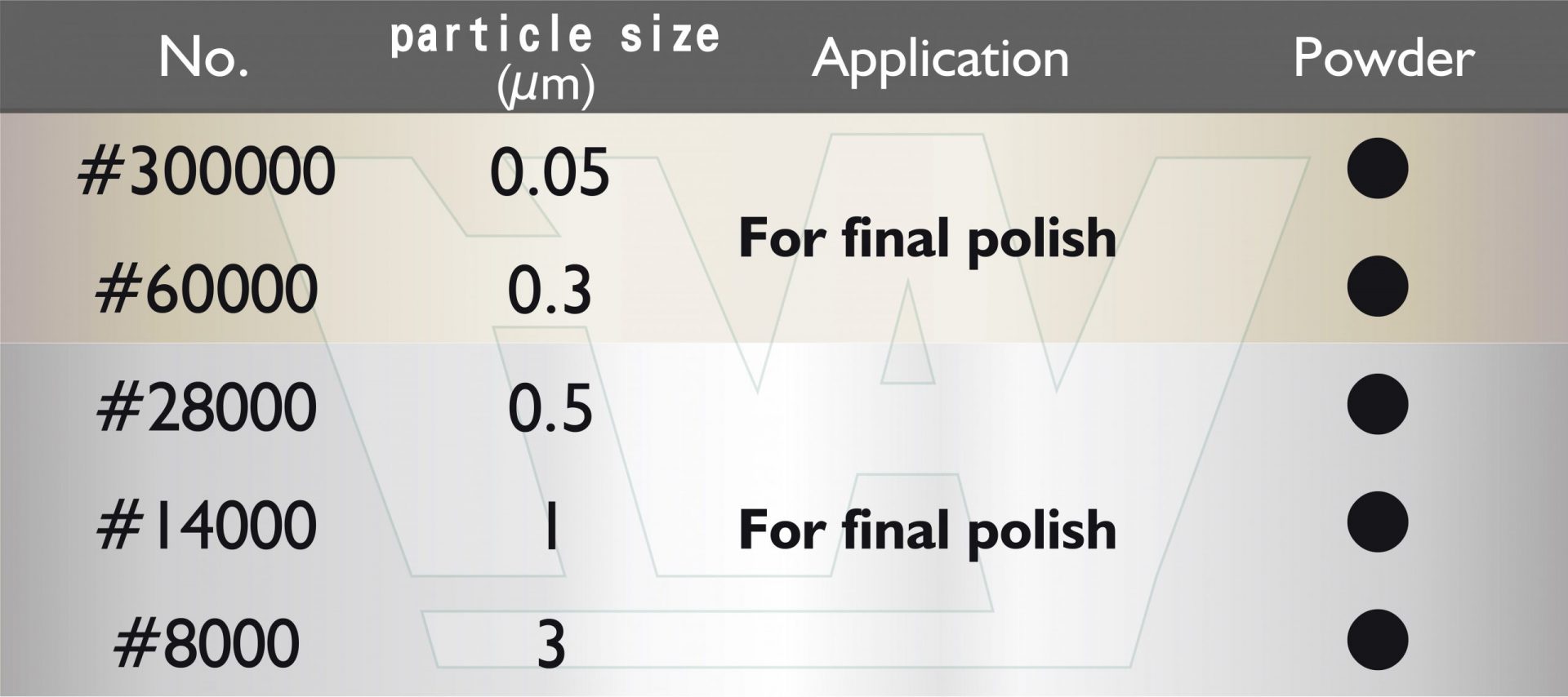

Product Specifications:

Do you have any questions? Contact Honway