HWS25 Wafer Packaging Dicing Blade – Hard Blade

Honway Materials provide customized services,

Make the most suitable wafer electroplated dicing blade for you

Suitable for processing semiconductor wafers, packaging substrates, ceramic LED substrates, semiconductor packaging substrates, and various hard and brittle materials like PZT and TGG.

Offering a choice of resin and metal base materials to meet various processing needs.

Product Features:

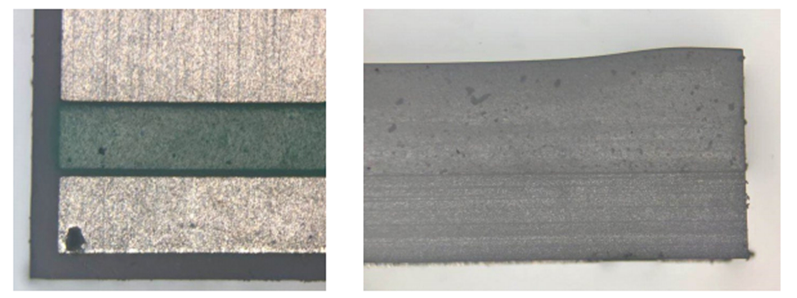

- High Wear Resistance and Blade Stability: The tool features excellent wear resistance and structural stability, effectively controlling the side steps of the chip particle and ensuring consistent particle size, which improves cutting yield and process stability.

-

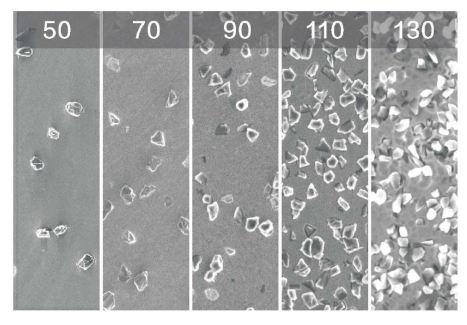

Strict Diamond Raw Material Control: Uses ultra-narrow particle size distribution of high-purity diamond micro-powder, paired with precision inspection technology, to effectively eliminate large, long-rod, and plate-like irregular particles, significantly reducing the risk of chipping on the front side of the wafer.

-

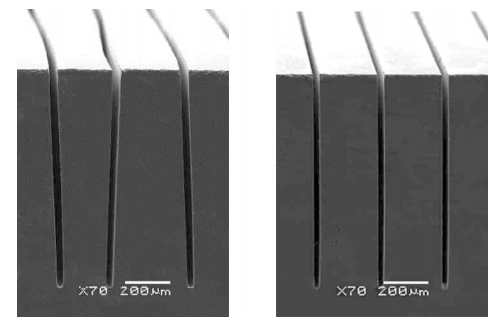

Ultra-High Blade Strength Design: A unique electroplating process achieves extremely high blade strength, which prevents “snake cutting” phenomena. When cutting thick wafers, it can also maintain the verticality of the die sides, preventing oblique cuts and ensuring stable processing under high loads.

-

Precision Process to Prevent Backside Chipping and Cracking: The cutting process is specifically designed for ultra-thin wafers and small-die wafers, effectively preventing backside chipping and cracking issues, and improving the integrity and quality of the finished product.

Uses:

- Resin Base: Suitable for processing hard materials.

- Metal Base: Provides a longer service life.

- Used during the semiconductor packaging cutting process stage.

- For processing difficult-to-cut materials, such as ceramic substrates with silicone.

Application areas:

- Suitable for hard and brittle materials such as ceramic LED substrates, semiconductor packaging substrates, PZT, and TGG.

Please specify the following when ordering dicing blades:

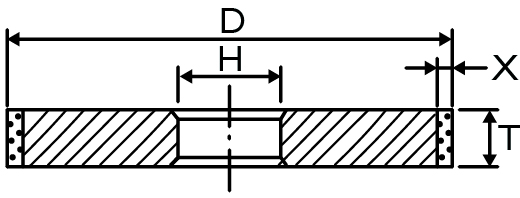

- Shape and dimensions of the dicing blade:

- Outer Diameter (mm): for example, 58

- Protrusion Amount (mm): 4.0

- Thickness (mm): for example, 0.20

- Thickness Tolerance (mm): for example, B ±0.010

- Grit Size: for example, #400

- Bond Type: for example, S sharp type

- Concentration: for example, 30

- Number of Grooves (pcs): for example, S48

- Use: for ceramic LED substrates

- Quantity and delivery time:

- RPM and processing conditions:

- Processing equipment model:

- Most manufacturers mark the following information on the dicing blades, with a specification example: 58×4.0×0.2B 400S30S48

| Outer Diameter (mm) | Exposure (mm) | Thickness (mm) | Thickness Tolerance (mm) | Grit Size | Bond type | Concentration (Volume concentration) | Numbers of Grooves (pcs) |

| 56

58 |

2.0

2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.6 |

0.06

0.08 0.10 0.12 0.14 0.16 0.18 0.20 0.22 0.24 0.26 0.28 0.30 0.32 |

A ±0.005

B ±0.010 C ±0.015 |

#340

#400 #500 #600 #800 #1000 #12 00 |

S Sharp Type

N General Type H High Strength Type |

30

50 70 90 110 130 150 |

S16

S32 S48 |

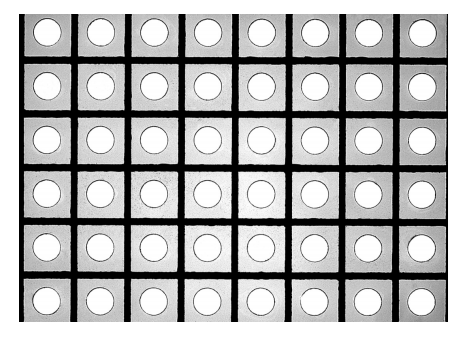

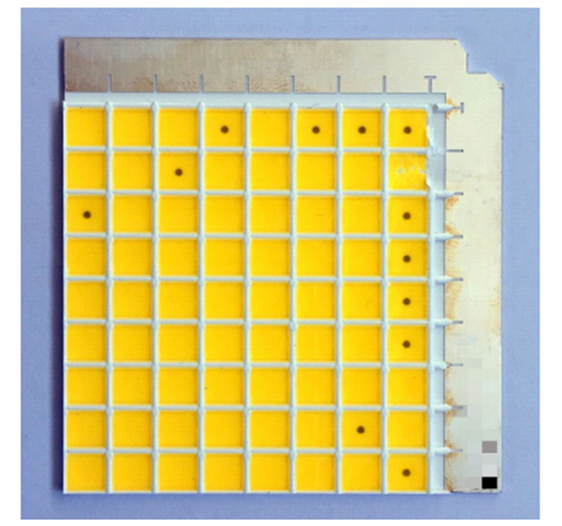

Sample images:

Product technical advantages:

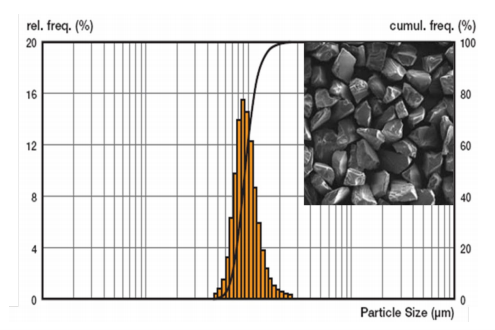

Carefully selected high-compactness diamond crystal shapes and uniform particle size distribution ensure the cleanliness of the machined surface and cutting stability, improving finished product yield.

By precisely controlling diamond concentration grades, the HWE25 series effectively balances processing stability and tool life. It shows outstanding performance, especially in reducing wafer backside chipping, to achieve high-yield and high-reliability cutting results.

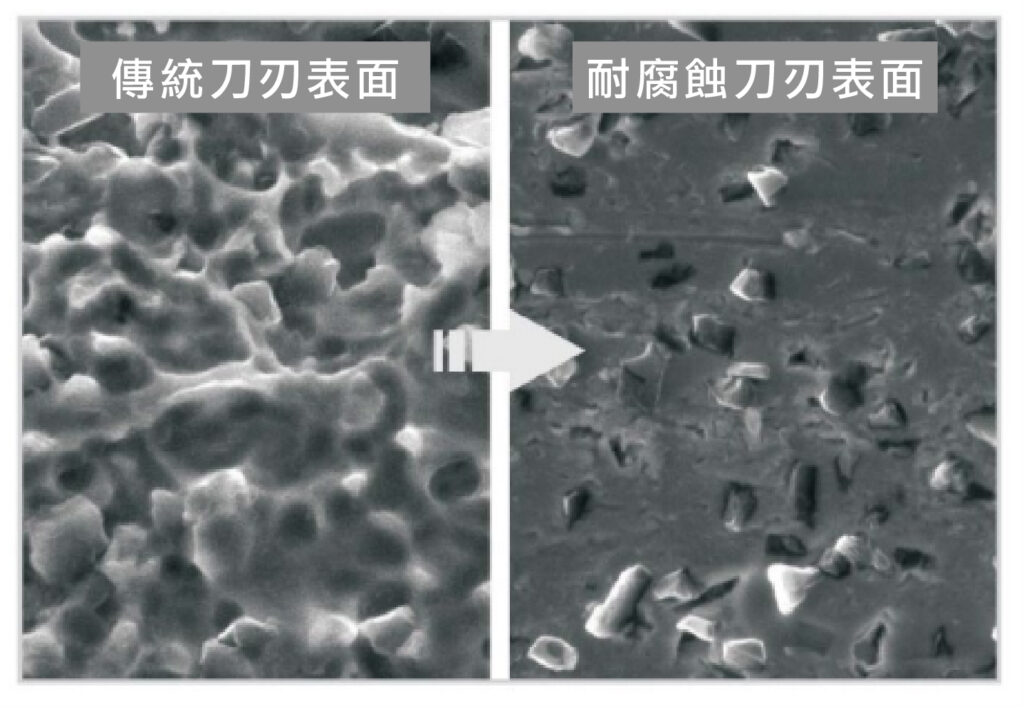

The blade possesses excellent chemical stability, effectively resisting corrosion risks in wet or CO₂-assisted cutting environments, significantly extending blade life.

The ultra-narrow kerf width, with a minimum of 10 μm, meets the dicing needs of high-density layouts and narrow street wafers like GaAs LEDs, improving wafer utilization and reducing material loss.

Suitable for high-speed operation environments, it can effectively prevent offset phenomena like “snake mark.

Use Case:

LED bead ceramic packaging substrate: No sealing on the front, back, or sides, no steps on the sides.

Precautions:

- Check the Dicing Blade: Before installation, be sure to carefully inspect the dicing blade for cracks or chips. If damage is found, stop using it immediately to prevent danger.

- Confirm Rotation Direction: Ensure that the rotation direction mark on the dicing blade matches the actual rotation direction of the machine’s spindle. Using it in reverse will affect the cutting effect and blade life.

- Use the Correct Blade: Only use dicing blades that meet the specifications of the machine tool and processing conditions, avoiding processing failure or equipment damage due to non-compliant specifications.

- Immediate Shutdown: During the processing, if abnormal sounds, vibrations, or non-smooth cutting occurs, immediately stop the machine’s operation and find the cause before continuing.

- Regular Dressing: When you find that the cutting efficiency decreases, you should dress the blade. Continuing to use a dull blade may lead to overheating, overload, or even breakage.

- Do Not Touch: When the dicing blade is rotating, it is strictly forbidden to touch it with your hands or other body parts to avoid personal injury.

Any questions? Contact HonWay