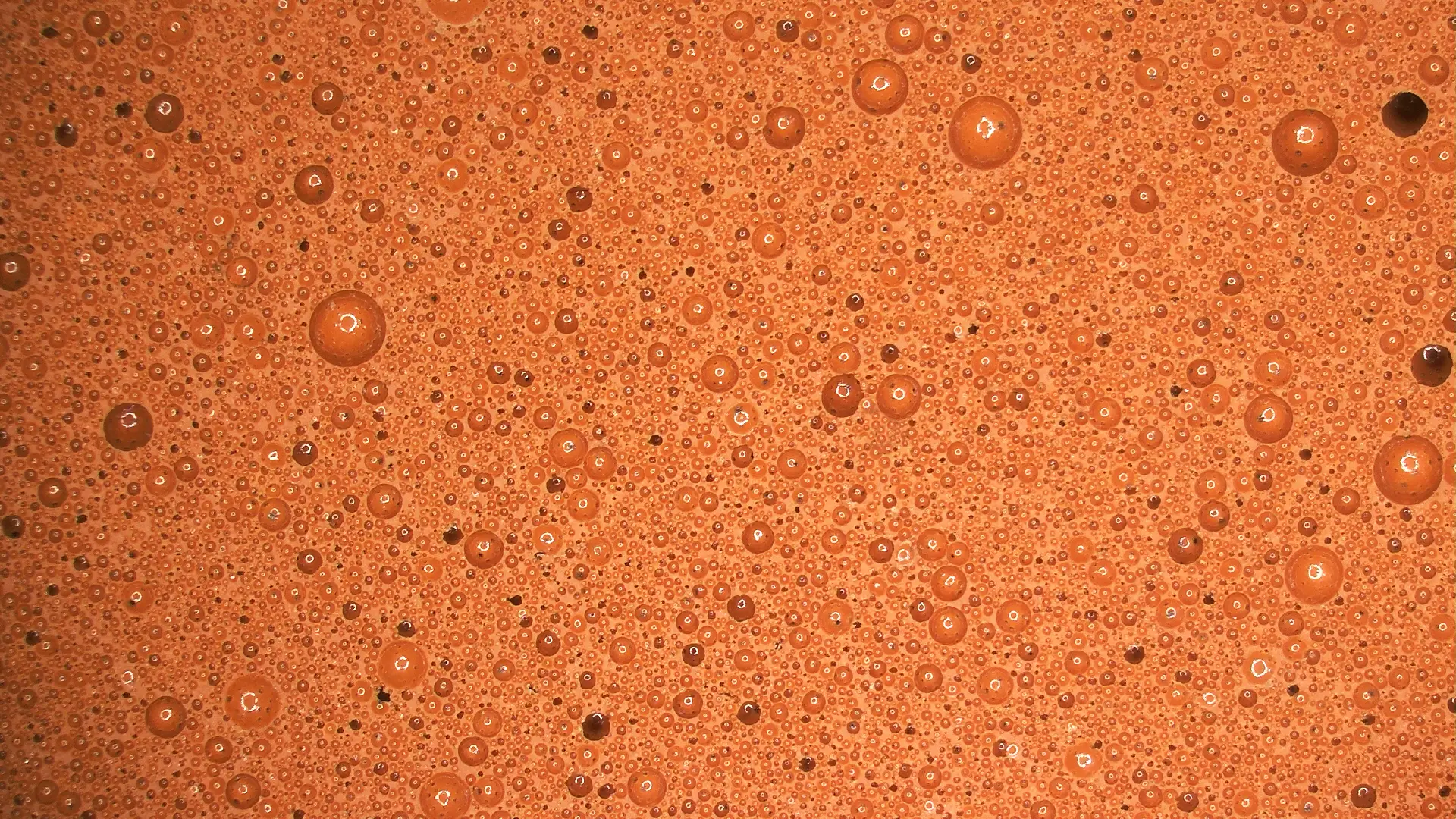

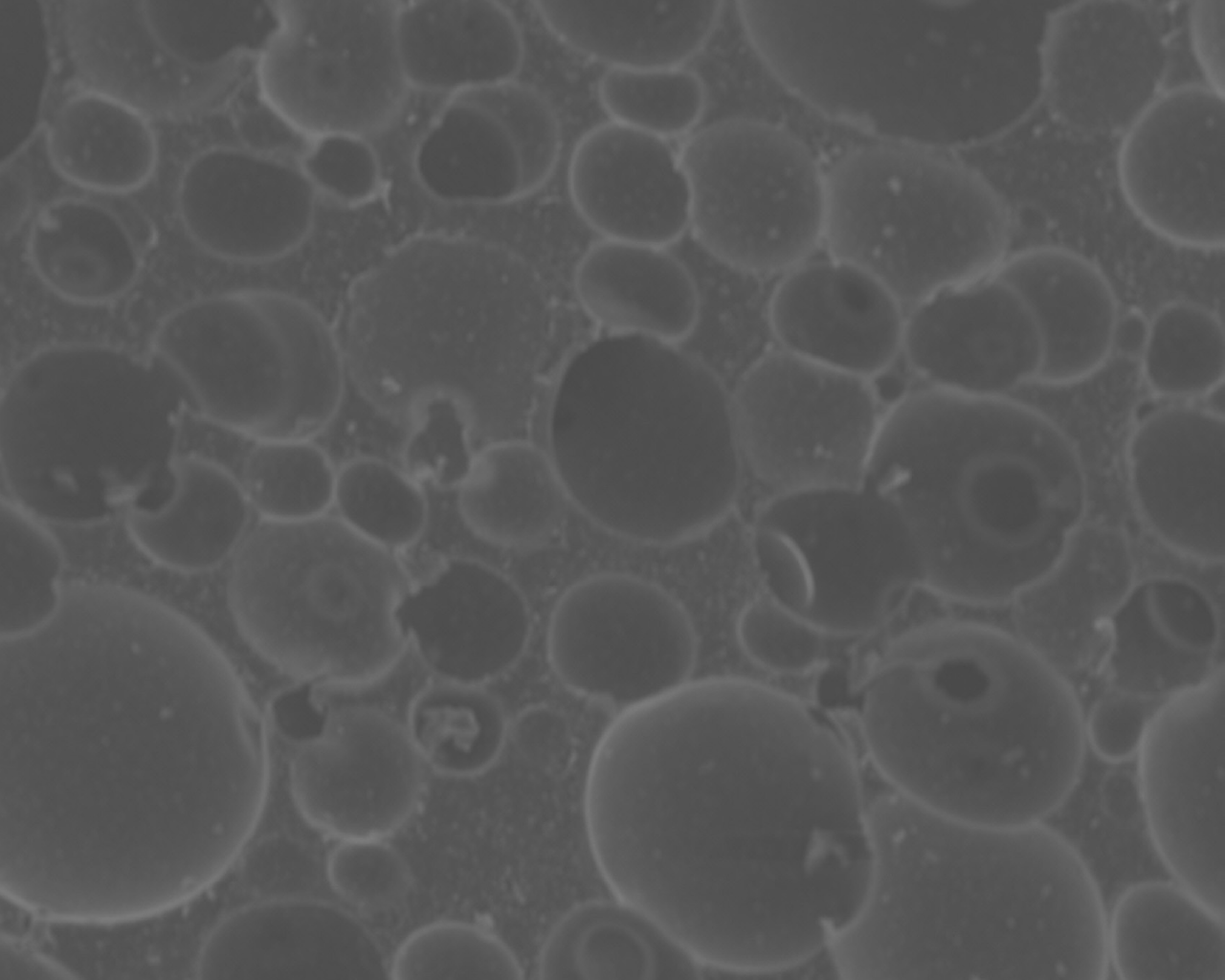

HW601-Cerium oxide metallographic polishing pads/cloths Product features

Polishing is done to remove fine scratches and grinding marks from the specimen, creating a bright, flawless mirror surface for more accurate observation. 1 It can be used with Honway’s monocrystalline and polycrystalline diamond polishing fluids/pastes, cerium oxide polishing fluid, aluminum oxide polishing fluid, etc.

•Matching abrasive ≥2um, suitable for precision polishing.

- High flatness, high wear resistance, high finish.

- Shore hardness: 75-85。

- We offer four kinds of products: non-adhesive polishing fabrics, adhesive backed polishing cloths, rubber backed magnetic polishing cloths, and rubber backed iron polishing cloths.

- Rubber backed polishing cloth is made of soft iron, if you need to order please contact customer service for price.

- The product offers two options: grooved and non-grooved.

- Thickness: 2.0mm, 2.5mm, 3.0mm.

Groove specification

| Thickness |

•0.5-5.0mm •Regular thickness is 2.0mm. |

| Groove width |

2.0±0.2mm |

| Groove depth |

0.7±0.2mm |

| Square size |

18±0.2mm |

Scope of Application

- Suitable for surface precision polishing of various glass materials such as crystal crafts, optical lenses, watch glass, semiconductors, precision optical instruments, LED substrates, silicon wafers, gemstones, crystal glass components, precision optical lenses, glass eyeglass lenses, watch cases, etc.

Product features

Outer diameter:

Ф200mm(Ф8in).Ф230mm(Ф9in).Ф250mm(Ф9.5in).Ф300mm(Ф12in), etc. Other sizes and specifications can also be customized.

※Contact customer service for customization, the maximum available diameter is Ø990mm.

1. Product advantages

| Other brand products | Honway Selection (Win) | Honway product selection advantages |

|

Polishing fabric Double-sided adhesive layer Release paper layer

Only three-layer design |

Polishing fabric Functional adhesive layer Reinforcement layer Double-sided adhesive layer Release paper layer |

Not easy to wrinkle Strong water resistance Not easy to fall off High flatness

|

2. How to Choose

※如何選擇拋光墊尺寸 無背膠拋光墊 > 機台盤 背膠拋光墊 = 機台盤 背磁拋光墊 = 機台盤

3. Precaution

- For optimal flatness, avoid sticking any labels or similar items to the bottom of the disc to prevent affecting workpiece flatness.

- The contact surface between the polishing pad and the machine must remain flat, clean, and dry to avoid affecting the flatness of the workpiece.

- After use, carefully remove the pad, rinse with water, and let it air dry.

- Do not bend or damage the polishing pad.

- When installing or removing, do so carefully to avoid magnetic attraction pinching your hands.