HW402-Polyurethane metallographic polishing pads/cloths Product features

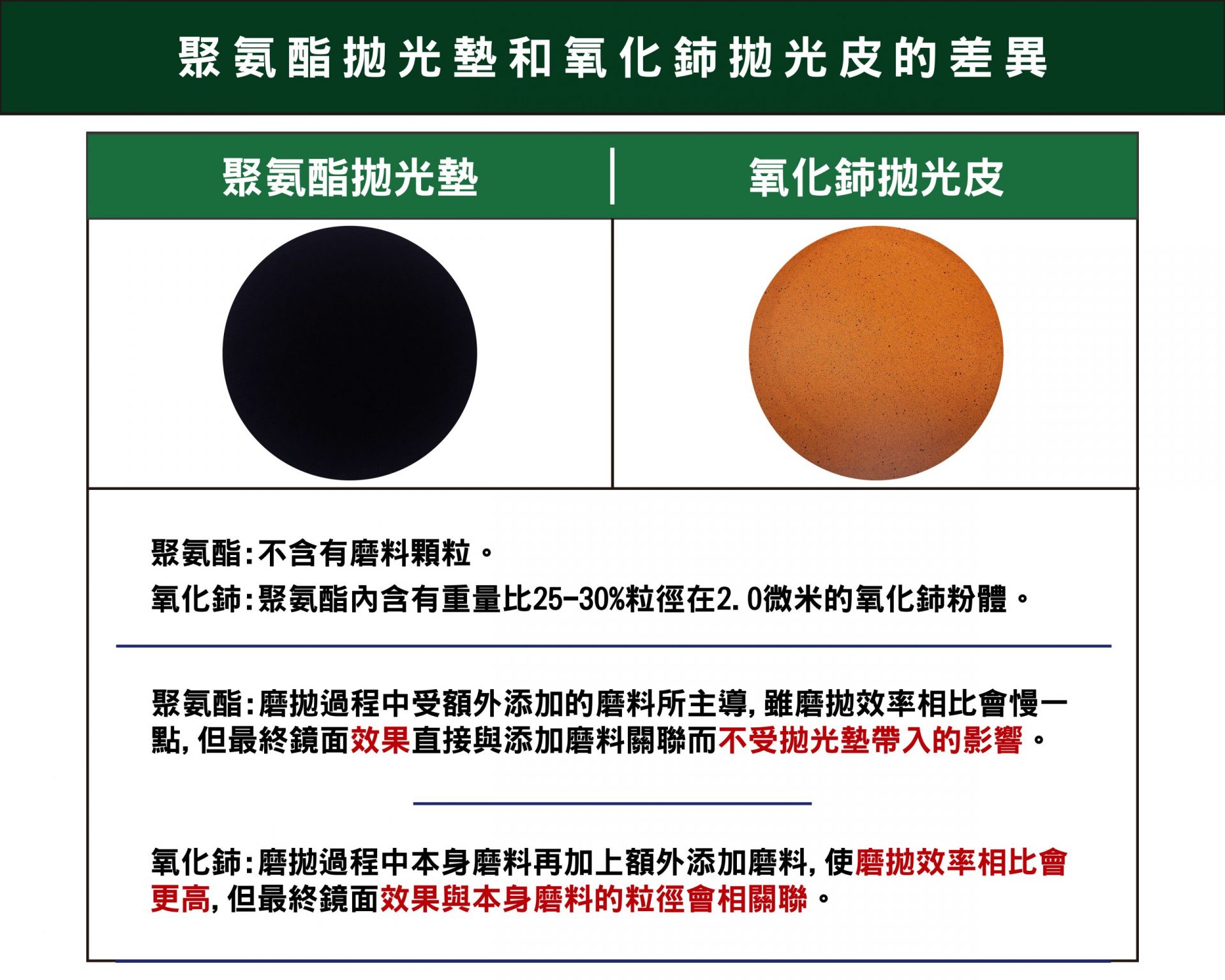

Polishing is done to remove fine scratches and grinding marks from the specimen, creating a bright, flawless mirror surface for more accurate observation. 1 It can be used with Honway’s monocrystalline and polycrystalline diamond polishing fluids/pastes, cerium oxide polishing fluid, aluminum oxide polishing fluid, etc.

Combined with abrasive ≤1.5um, it is suitable for intermediate polishing.

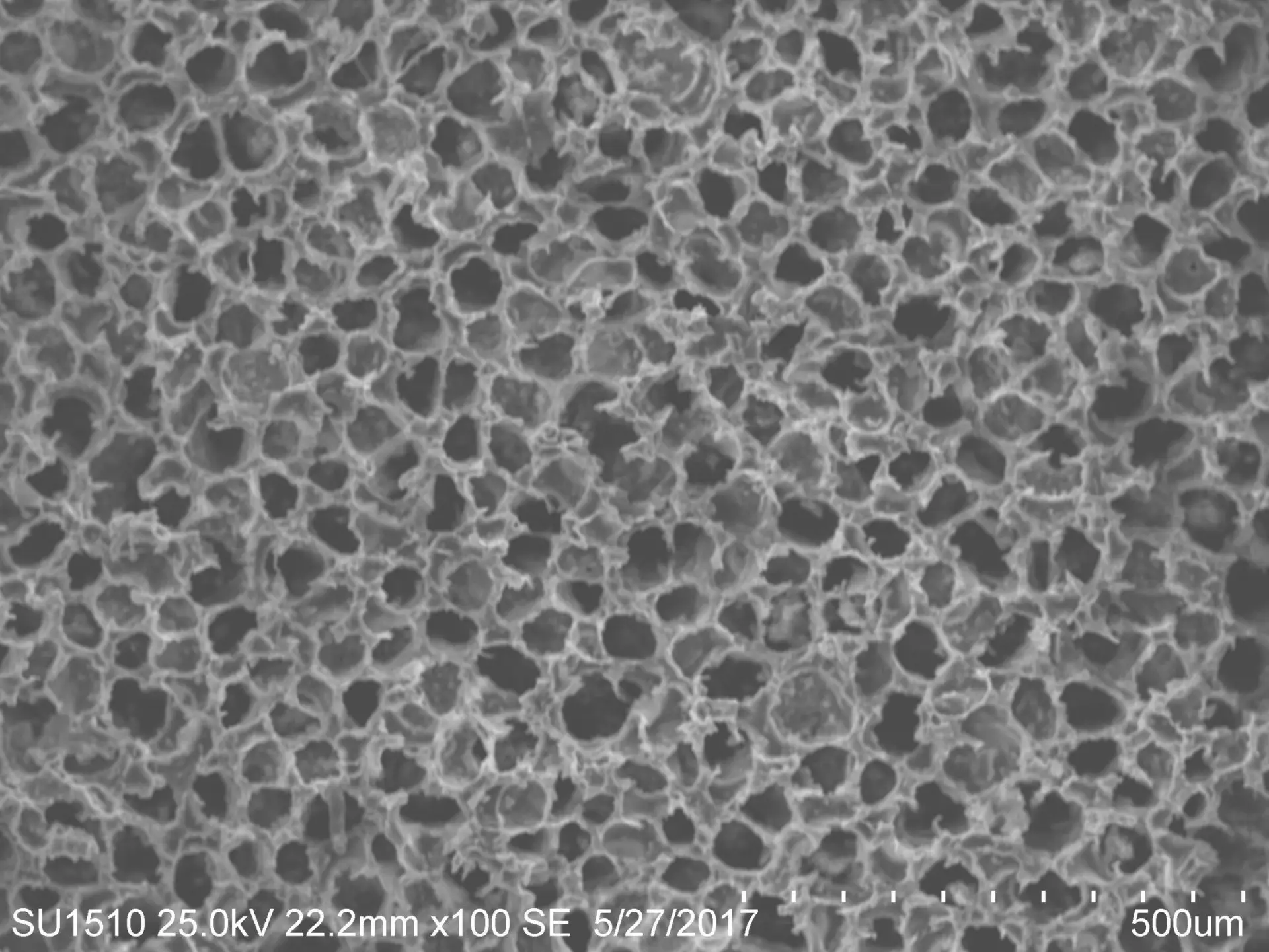

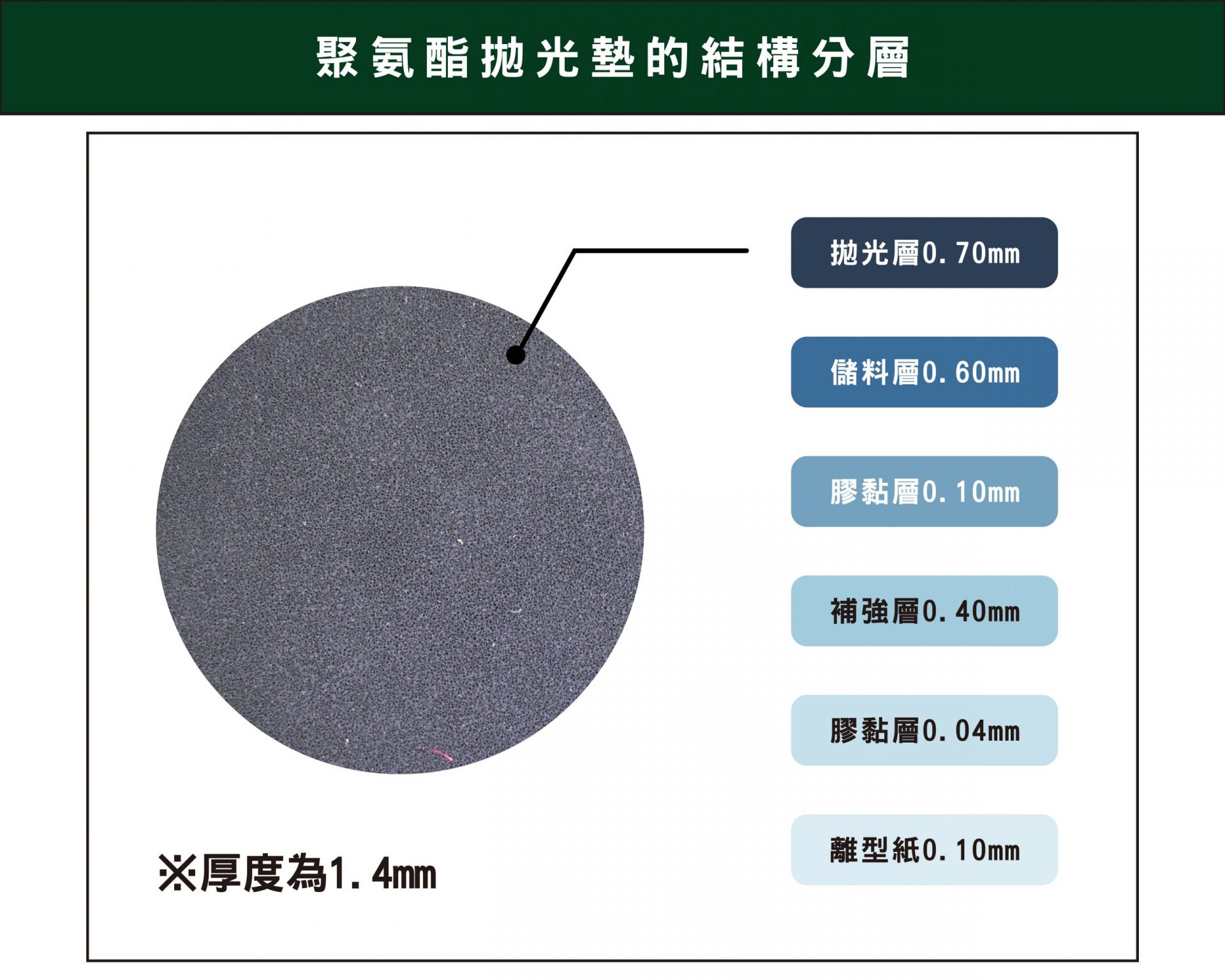

- The polyurethane polishing pad series is a highly flat, porous synthetic material. The product features a smooth surface and consists of a polishing layer, an abrasive storage layer, and a protective layer. It is made from a special vertical microporous structure that grows on a polyurethane base material.

- The pressure between the workpiece and the polishing pad causes the vertical microporous structure to act as a pump that enables the fast flow of abrasives, providing an excellent surface polishing process. This vertical microporous structure enhances the carrying capacity of the polishing pad and extends its lifespan.

- We offer four kinds of products: non-adhesive polishing fabrics, adhesive backed polishing cloths, rubber backed magnetic polishing cloths, and rubber backed iron polishing cloths.

- Rubber backed polishing cloth is made of soft iron, if you need to order please contact customer service for price.

Scope of Application

- It is suitable for polishing electrodes made of gold, silver, platinum, graphite; as well as for optical fibers, resin-cured bodies, flat polishing machines, resin crafts, crystal crafts, instruments, soft metals, optical glass, electronic semiconductors, precision optical lenses, gemstones, and metallographic sections.

Product features

outer diameter: Ф127mm(Ф5in).Ф200mm(Ф8in).Ф230mm(Ф9in).Ф250mm(Ф9.5in).Ф300mm(Ф12in).Ф350mm(Ф14in).Ф380mm(Ф15in).Ф500mm(Ф20in).Ф650mm(Ф26in)etc.Other sizes can be customized.

1. Product advantages

| Other brand products | Honway Selection (Win) | Honway product selection advantages |

|

Polishing fabric Double-sided adhesive layer Release paper layer

Only three-layer design |

Polishing fabric Functional adhesive layer Reinforcement layer Double-sided adhesive layer Release paper layer |

Not easy to wrinkle Strong water resistance Not easy to fall off High flatness

|

2. How to Choose

※如何選擇拋光墊尺寸 無背膠拋光墊 > 機台盤 背膠拋光墊 = 機台盤 背磁拋光墊 = 機台盤

3. Precaution

- For optimal flatness, avoid sticking any labels or similar items to the bottom of the disc to prevent affecting workpiece flatness.

- The contact surface between the polishing pad and the machine must remain flat, clean, and dry to avoid affecting the flatness of the workpiece.

- After use, carefully remove the pad, rinse with water, and let it air dry.

- Do not bend or damage the polishing pad.

- When installing or removing, do so carefully to avoid magnetic attraction pinching your hands.

4. Others