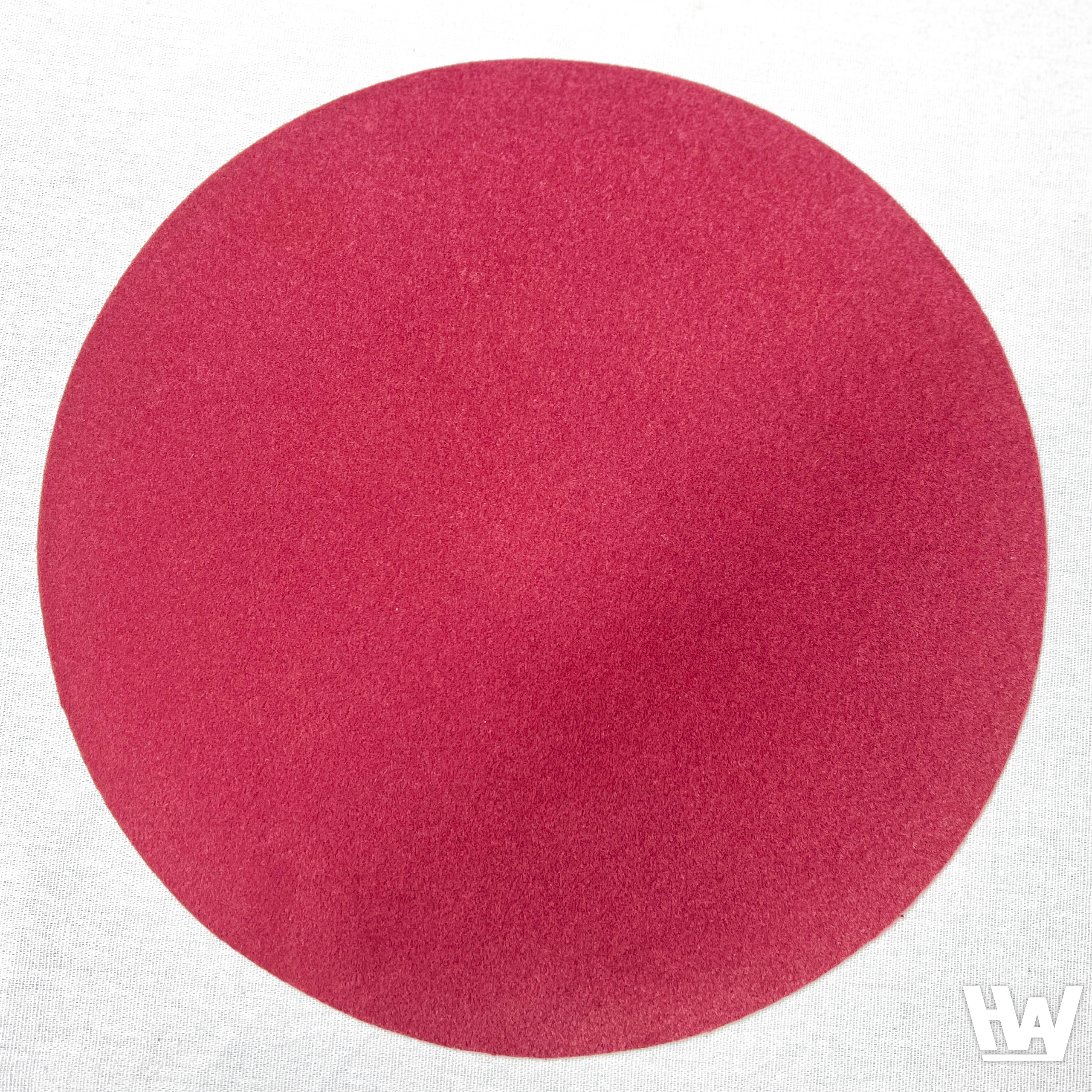

HW301-Flocking and Velveteen metallographic polishing pads/cloths Product features

Polishing is done to remove fine scratches and grinding marks from the specimen, creating a bright, flawless mirror surface for more accurate observation. 1 It can be used with Honway’s monocrystalline and polycrystalline diamond polishing fluids/pastes, cerium oxide polishing fluid, aluminum oxide polishing fluid, etc.

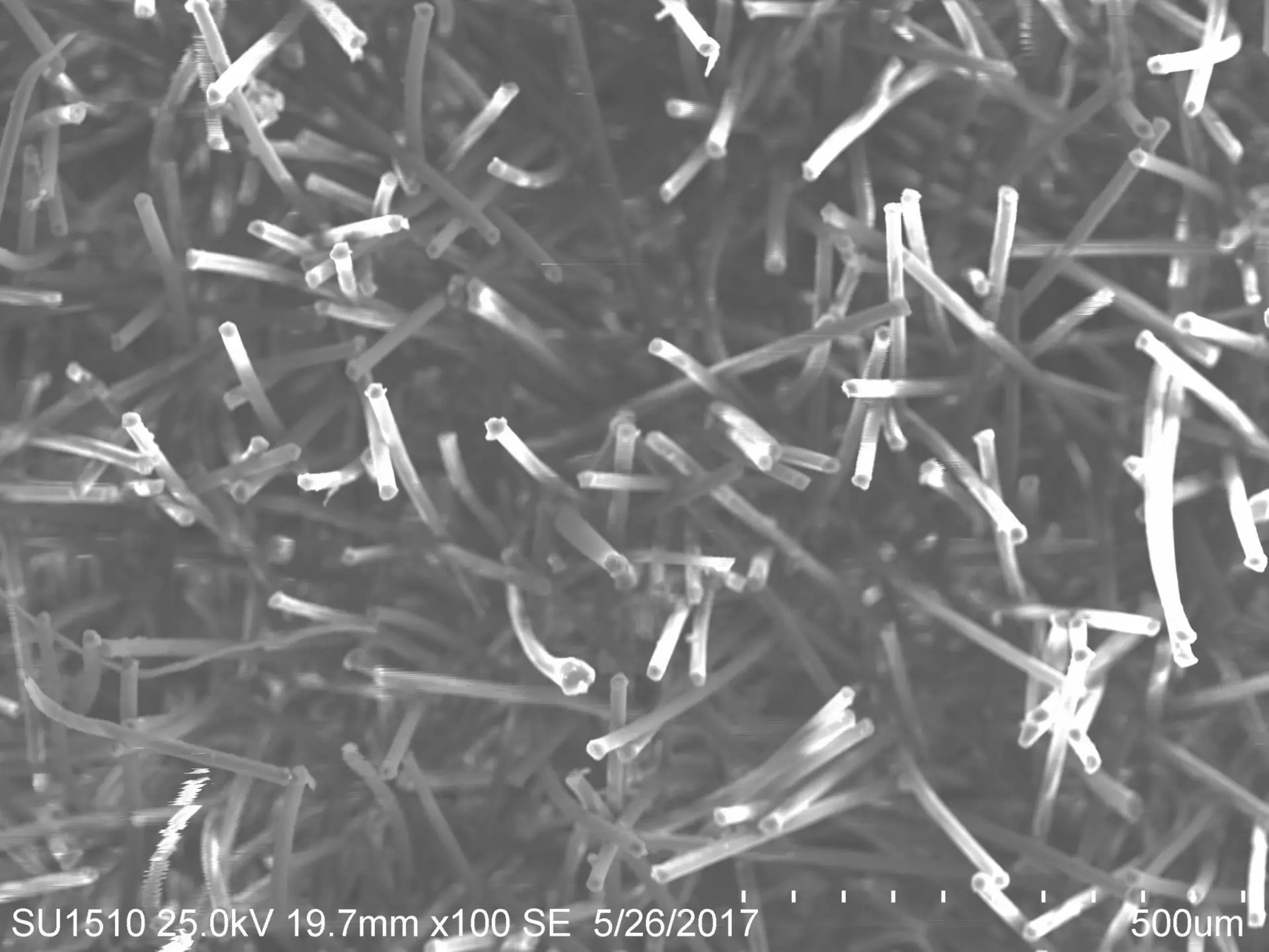

Combined with abrasive 2-7um, it is suitable for intermediate polishing.

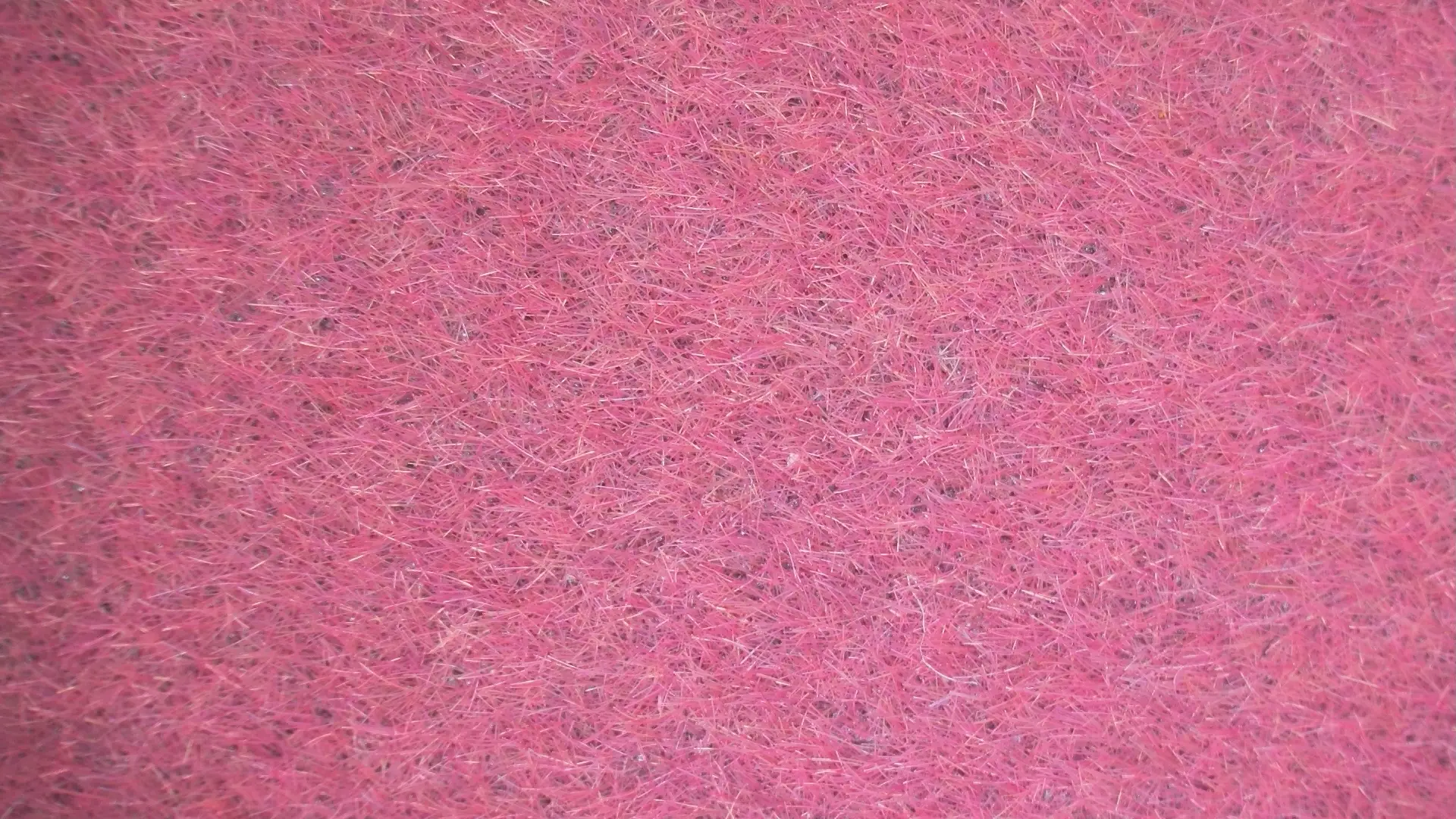

- The polishing surface is a soft precision polishing fabric made of synthetic flocking and velveteen polishing fabric.

- The adhesive-backed product features a waterproof layer and reinforced design, making it resistant to water, oil, and alcohol. It minimizes the rounding of polished edges, ensuring higher flatness.

- We offer four kinds of products: non-adhesive polishing fabrics, adhesive backed polishing cloths, rubber backed magnetic polishing cloths, and rubber backed iron polishing cloths.

- Rubber backed polishing cloth is made of soft iron, if you need to order please contact customer service for price.

Scope of Application

- It is suitable for final polishing of steel, metal alloys, non-metallic materials, electronic components, polymers, ceramics, heat-treated surfaces, and metallographic sections of metals.

Product features

Outer diameter:

Ф127mm(Ф5in).Ф200mm(Ф8in).Ф230mm(Ф9in).Ф250mm(Ф9.5in).Ф300mm(Ф12in).Ф350mm(Ф14in).Ф380mm(Ф15in), etc. Other sizes and specifications can also be customized.

1. Product advantages

| Other brand products | Honway Selection (Win) | Honway product selection advantages |

|

Polishing fabric Double-sided adhesive layer Release paper layer

Only three-layer design |

Polishing fabric Functional adhesive layer Reinforcement layer Double-sided adhesive layer Release paper layer |

Not easy to wrinkle Strong water resistance Not easy to fall off High flatness

|

2. How to Choose

※如何選擇拋光墊尺寸 無背膠拋光墊 > 機台盤 背膠拋光墊 = 機台盤 背磁拋光墊 = 機台盤

3. Precaution

- For optimal flatness, avoid sticking any labels or similar items to the bottom of the disc to prevent affecting workpiece flatness.

- The contact surface between the polishing pad and the machine must remain flat, clean, and dry to avoid affecting the flatness of the workpiece.

- After use, carefully remove the pad, rinse with water, and let it air dry.

- Do not bend or damage the polishing pad.

- When installing or removing, do so carefully to avoid magnetic attraction pinching your hands.