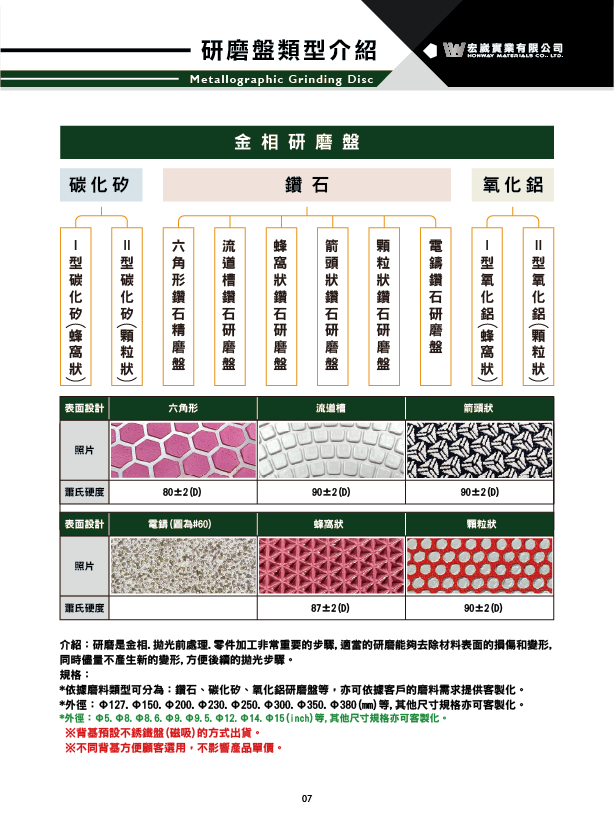

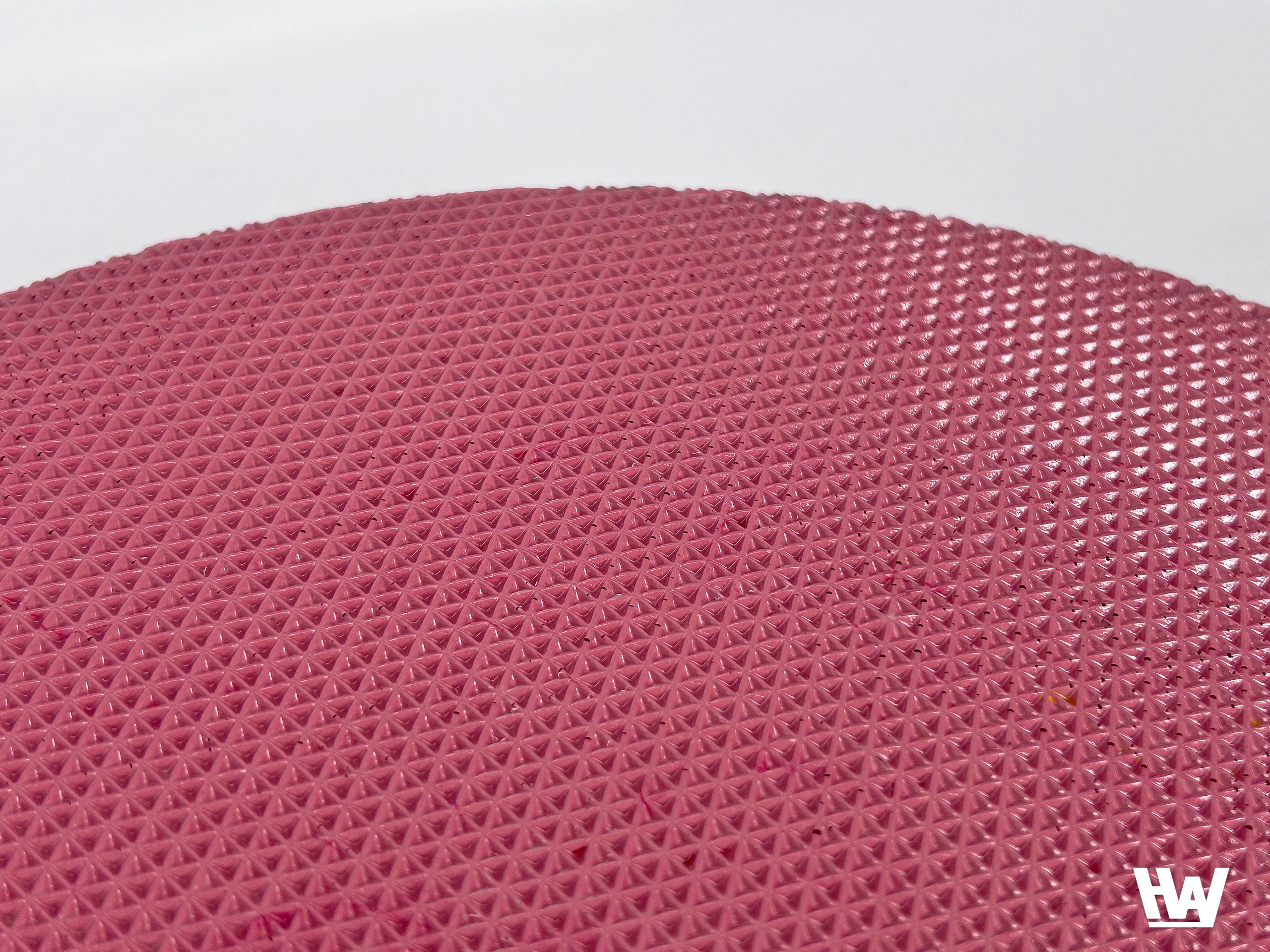

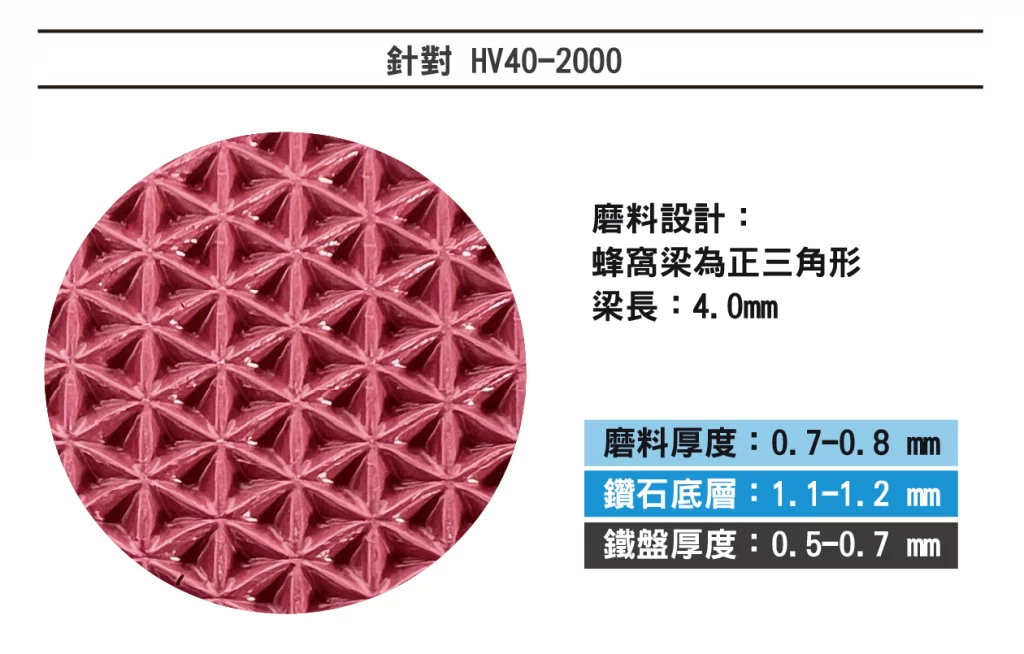

HW-Primo(honeycomb shape) Product feature

This product allows the elimination of metallographic sandpaper grinding and polishing steps. The continuous lubricant supply optimizes diamond grain interaction with the workpiece in the disc’s working layer. The surface architecture ensures enhanced sample flatness across all applications.

• Built with high-performance diamond in a honeycomb formation, providing options for hard materials in hardness ranges from HV40 up to HV2000.

• Metals: High-speed steels, alloy steels, hard metals/carbides, tungsten steels, tungsten carbides, and similar.

• Non-metals: Glasses, ceramics, agates, natural stones, gemstones, jades, monocrystalline silicons, polycrystalline silicons, quartz glasses, titanium carbides, magnetic materials, and others.

Application areas:

- Materials science, metal identification, failure analysis, manufacturing, materials research and development, diamond and gemstone craftsmanship, electronics and the semiconductor industry.

- Double-sided lapping machine, single-side lapping machine.

Product features

| Number | Particle size(um) | size(mm) | size(inch) |

| 60# | 240 | Ø200

Ø220 Ø230 Ø250 Ø300 Ø350 Ø380 |

Ø8

Ø8.6 Ø9 Ø9.5 Ø12 Ø14 Ø15 |

| 80# | 188 | ||

| 120# | 127 | ||

| 180# | 78 | ||

| 240# | 58 | ||

| 320# | 46 | ||

| 400# | 35 | ||

| 600# | 26 | ||

| 800# | 22 | ||

| 1000# | 18 | ||

| 1200# | 15 | ||

| 1500# | 12 | ||

| 2000# | 9.0 | ||

| 2400# | 6.0 | ||

| 4000# | 3.0 | ||

| 7000# | 0.5 |

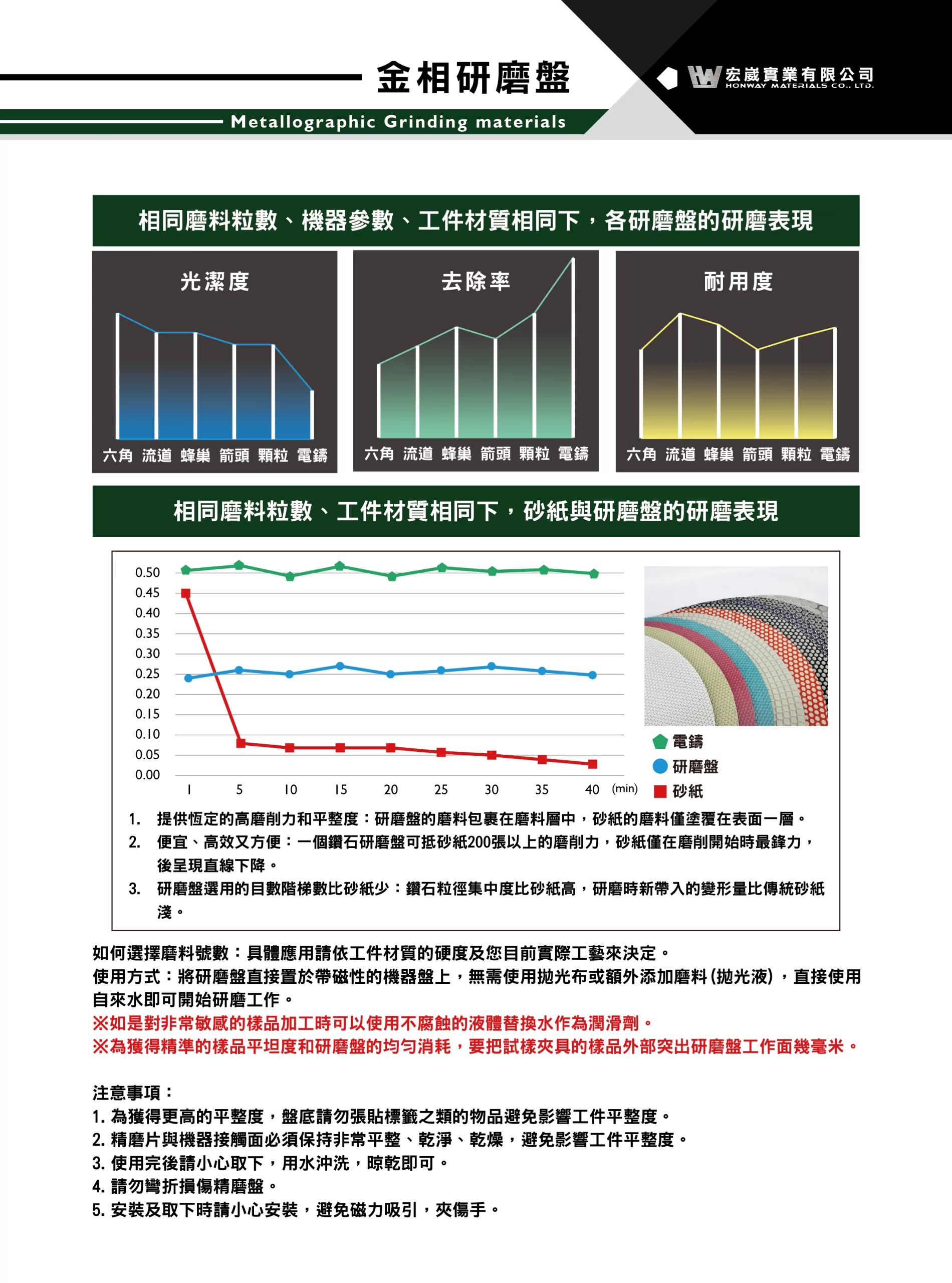

1. Product differences

| Metallographic fine grinding disc | Metallographic grinding disc | |

| Abrasive layer | soft | hard |

| Shore hardness | 80 degrees | 90 degrees |

| Introduction | Soft as cowhide | Hard as steel |

| Application | Replaces the three processes of back-end grinding and front-end polishing | Replaces sandpaper for grinding super-hard materials |

2. How to Choose

The specific application depends on the hardness of the workpiece material and your current actual process.

How to use: Place the grinding disc directly on the magnetic machine disc. No need to use polishing cloth or add additional abrasive (polishing liquid). Just use tap water to start grinding.

※When processing very sensitive samples, non-corrosive liquids can be used instead of water as lubricants.

※In order to obtain accurate sample flatness and uniform consumption of the grinding disc, the outer part of the sample holder should protrude a few millimeters from the working surface of the grinding disc.

3. Precaution

- For optimal flatness, avoid sticking any labels or similar items to the bottom of the disc to prevent affecting workpiece flatness.

- Ensure that the contact surface between the grinding disc and the machine is very flat, clean, and dry to avoid impacting the workpiece’s flatness.

- After use, carefully remove the pad, rinse with water, and let it air dry.

- Avoid bending or damaging the precision grinding disc.

- When installing or removing, do so carefully to avoid magnetic attraction pinching your hands.

4. Others