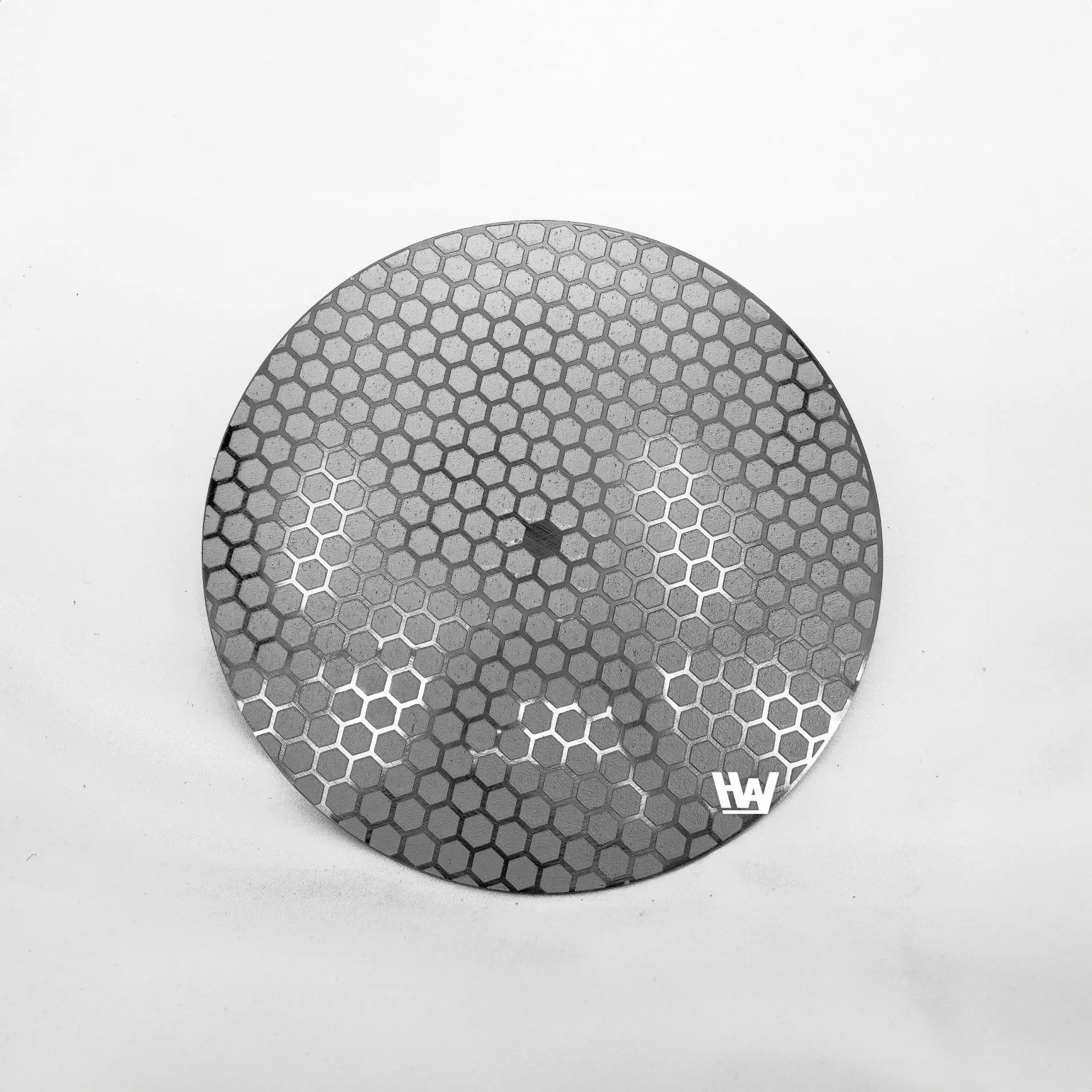

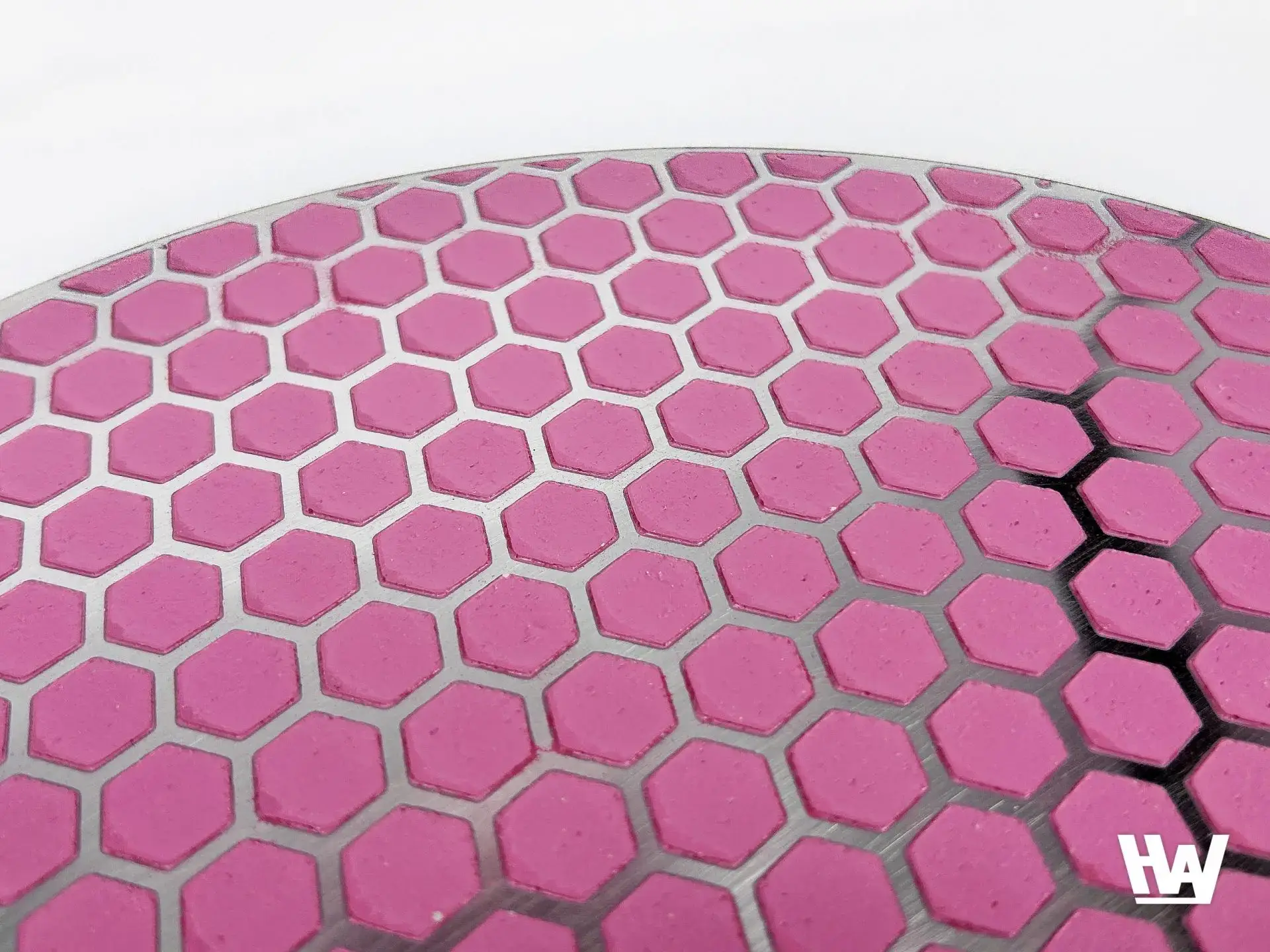

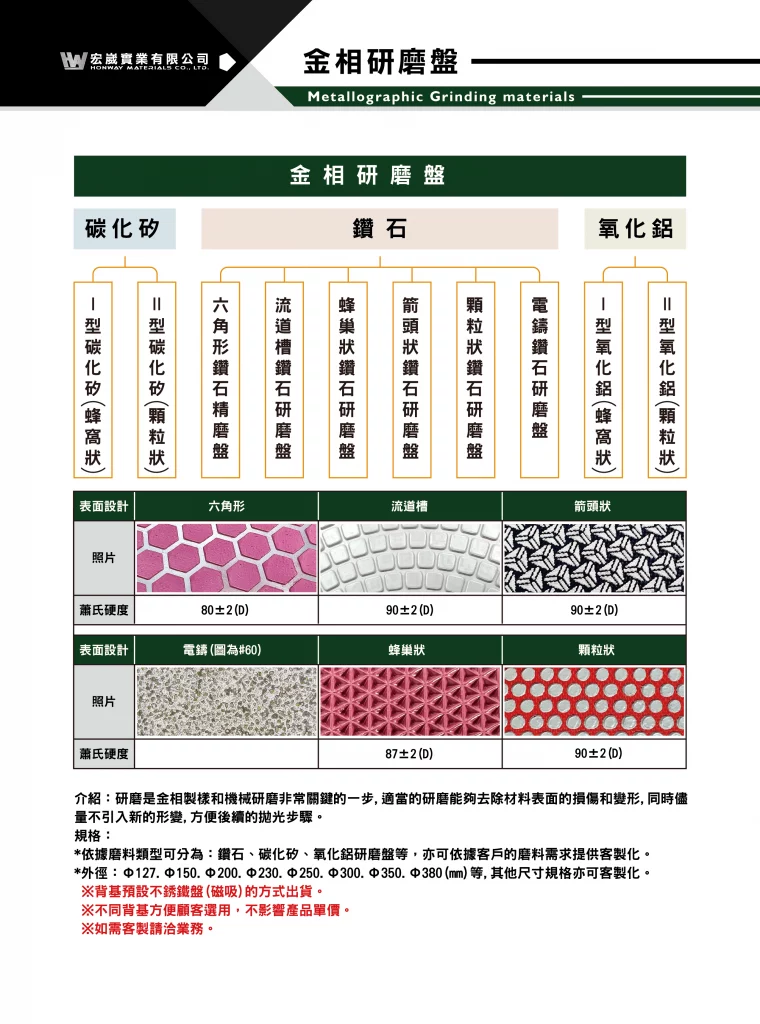

HW-Largo (Hexagonal) – Metallographic fine grinding disc Product features

☑️ Reduce process / Combined back-end grinding and front-end polishing, enhancing work efficiency.

☑️ Highly efficient / Flexible backing plus high quality abrasives, small residual scratch on the cut surface, improving subsequent polishing quality.

☑️ Widely applicable / Soft fine grinding discs are available with different abrasive types and grit sizes, suitable for workpieces of varying hardness.

☑️ High Flatness / Uniformly fine grinds both soft and hard materials, preventing rounding or chamfering, and ensuring sample consistency.

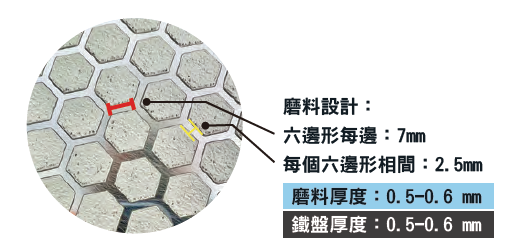

☑️ High Quality and Efficiency / Grid pattern reduces debris accumulation, provides consistent high removal rate, and ensures cross-sectional flatness.

Application areas:

- Materials science, metal identification, failure analysis, manufacturing, materials research and development, diamond and gemstone processing, electronics and semiconductor industries.

- Copper-clad laminates, double-sided grinders, and single-disc grinders.

Product features

|

Abrasive |

Particle size(um) | Size(mm) |

Size(in) |

| Diamond | 0.5

1.0 2.0 3.0 6.0 9.0 |

Ø127

Ø200 Ø220 Ø230 Ø250 Ø300 Ø350 Ø380

|

Ø5

Ø8 Ø8.6 Ø9 Ø9.5 Ø12 Ø14 Ø15

|

| Aluminum Oxide | |||

| Silicon carbide | |||

| Cerium Oxide | 0.5

1.0 2.0 3.0

|

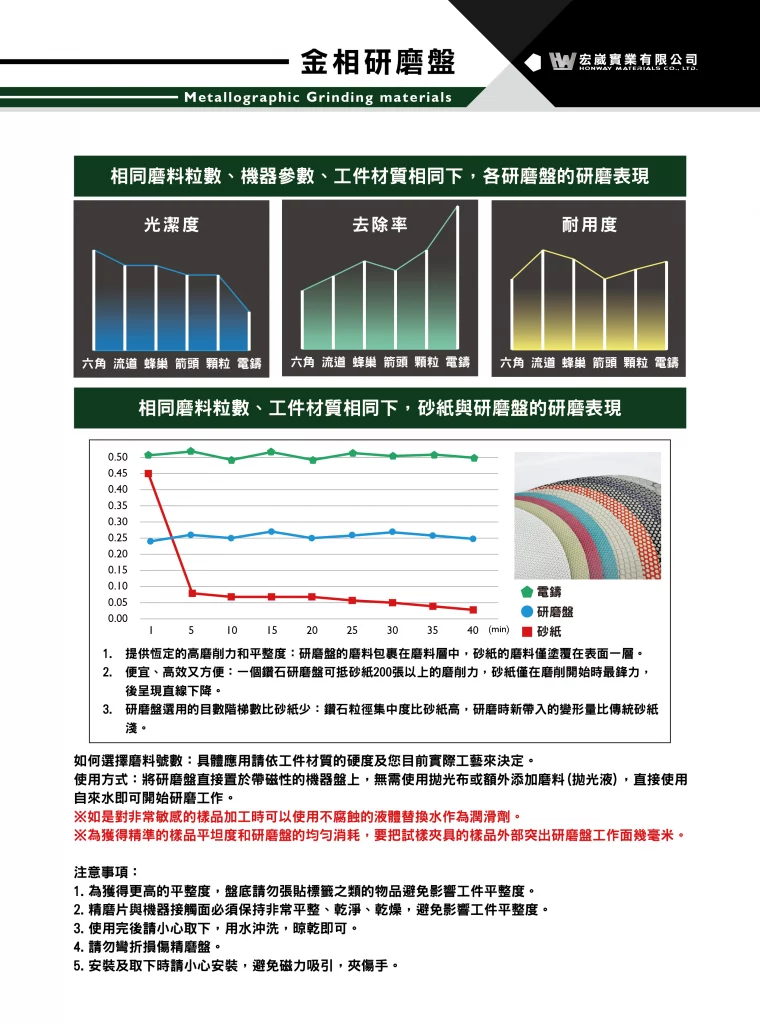

1. Product differences

| Metallographic fine grinding disc | Metallographic grinding disc | |

| Abrasive layer | soft | hard |

| Shore hardness | 80 degrees | 90 degrees |

| Introduction | Soft as cowhide | Hard as steel |

| Application | Replaces the three processes of back-end grinding and front-end polishing | Replaces sandpaper for grinding super-hard materials |

2. How to Choose

How to choose abrasives: The specific application depends on the hardness of the workpiece material and your current actual process. like:

- Diamond: super cemented carbide, electronic materials, ceramics.

- Aluminum oxide: soft metal, plastic, glass, IC substrate, packaging materials, semiconductors and various electronic parts, printed circuit boards (PCB) and connectors.

- Silicon Carbide (SiC): Suitable for semiconductor materials (such as silicon wafers and gallium arsenide), electronic materials, superhard metals, ceramics, glass, and gemstones.

- Cerium Oxide (CeO₂): Used for optical glass (lenses, prisms, and other optical components), gemstones, ceramics, semiconductors (such as wafers), and cubic zirconia.

(Note: The above applications are for reference only. The specific use should depend on the hardness of the workpiece material and your current process requirements.)

Grit size selection: The 3.0um (4000#) fine grinding disk facilitates a seamless progression from a preceding 6.0um (2400#) grinding stage to a subsequent 1.0um polishing stage, followed by a final, precision polishing step using a polishing cloth devoid of polishing slurry.

Usage instructions: Simply place the fine grinding disc directly onto the magnetic machine plate. No polishing cloth or additional abrasives (polishing liquid) are needed; you can begin fine grinding using tap water.

3. Precautions

- For optimal flatness, avoid sticking any labels or similar items to the bottom of the disc to prevent affecting workpiece flatness.

- Ensure that the contact surface between the grinding disc and the machine is very flat, clean, and dry to avoid impacting the workpiece’s flatness.

- After use, carefully remove the pad, rinse with water, and let it air dry.

- Avoid bending or damaging the precision grinding disc.

- When installing or removing, do so carefully to avoid magnetic attraction pinching your hands.