HCD.RZX Flaky PCD Cutters Product Features

Adjusting diamond micropowder particle sizes provide excellent wear resistance and blade strength, especially suitable for large-diameter drill bits, enhancing drilling efficiency.

- Offers advantages such as rapid chip removal, low cost, and easy welding.

- Adjusting the diamond microparticle size enhances tool wear resistance and cutting precision.

- Structural design simplifies the machining process.

- The flaky diamond cutting blade primarily utilizes the sharp corners and sides of the diamond to form the main cutting edge for processing.

- Coupling with coarse-grain diamond significantly boosts drilling efficiency.

Application areas:

- Particularly suitable for large-diameter drill bit machining, applicable in construction and stone processing industries.

- Suitable for CoWos process, capable of cutting various semiconductor substrates, such as silicon carbide, glass, ceramic, and alumina substrates.

Product features

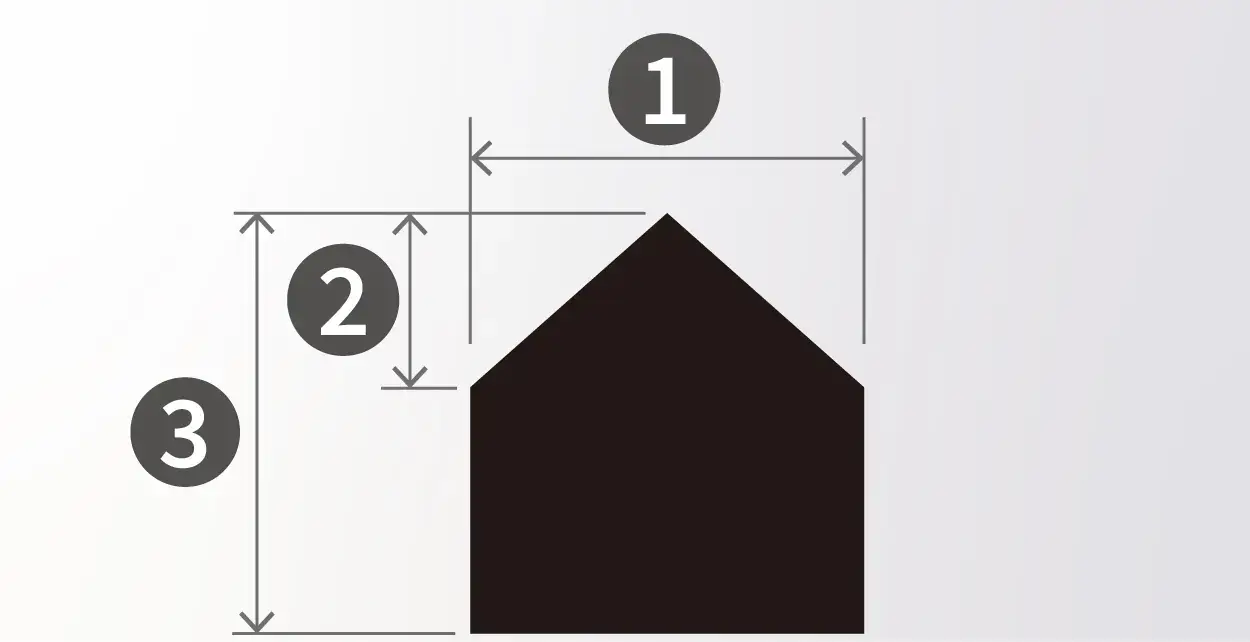

| Model | Product Types | Application | Granularity | 1. Diameter | Helix Angle | 2. Blade Length | 3. Matrix |

| HCD.RZX | Flaky | Drilling | Thin

Medium Thick |

∅6~∅20 | 30° | 10~25 | 10~25 |

※ Unit of size(MM)

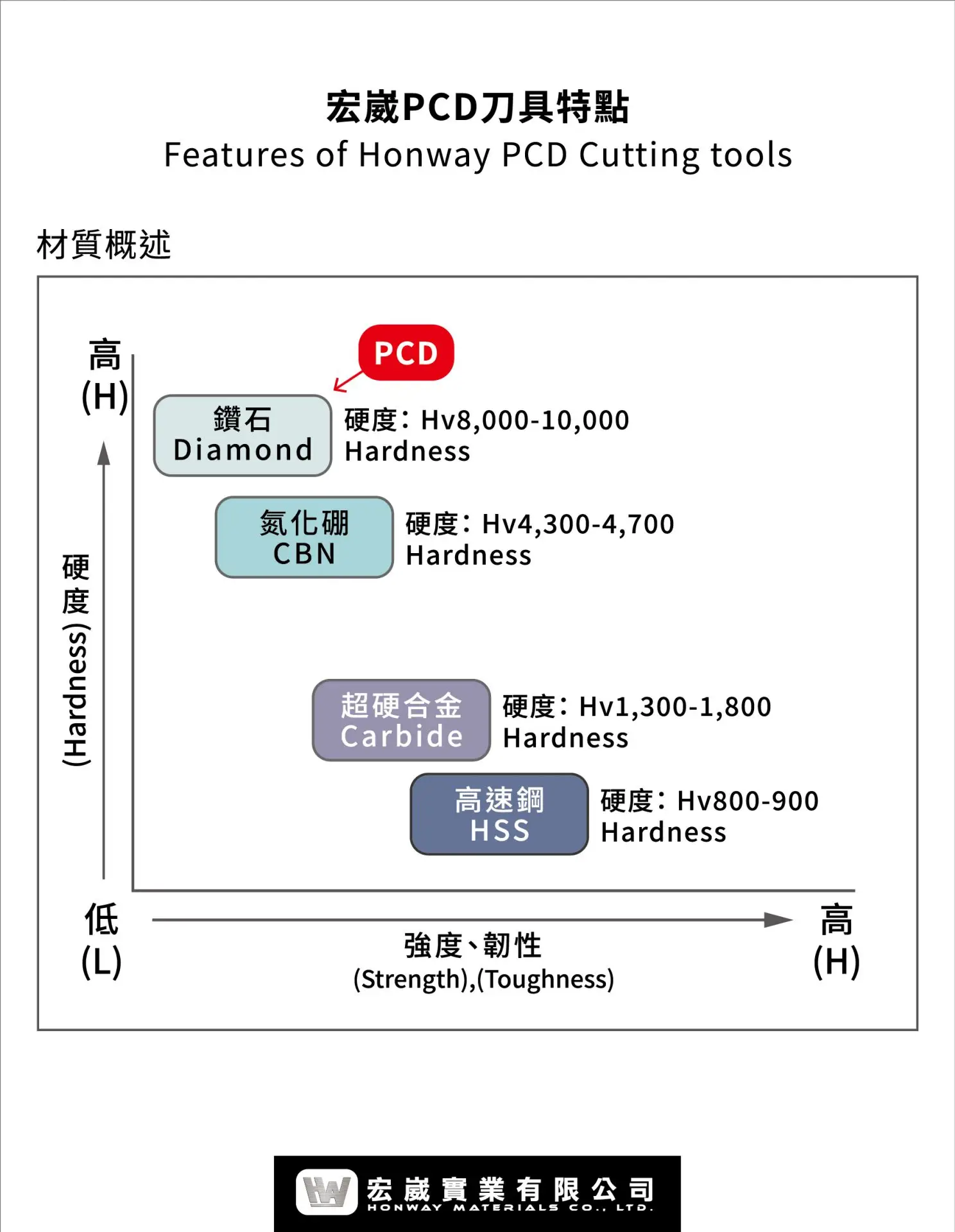

Material characteristics

Please note

1. Inclination Angle: Single-point PCD tools should not be aligned perpendicular to the grinding wheel center; they typically need to be inclined 10-15°.

2. Careful Placement: When placing the PCD tool into the collet, be sure to avoid collisions between the tool and the grinding wheel surface to prevent damage to the tool or the grinding wheel.

3. Avoid Overheating Damage: Do not quench hot dressing tools. When performing dry dressing, allow sufficient time for the PCD tool to cool down fully to avoid damage caused by overheating.

4. Select Appropriate Tools: When ordering PCD tools, consider the tool’s applicable range. Especially when machining ferrous metals, the chemical reaction between diamond and carbon in steel may accelerate tool wear.

5. Maintenance and Cleaning: When replacing tools, remove all broken tool fragments first to prevent secondary damage to the tools. Ensure that the processing equipment is stable, as unstable equipment is prone to vibrations, which can cause the tools to break.

6. Storage: When storing PDC tools, place them separately and do not place the tips facing each other to avoid damage to the tools.