Chamfering and Grinding Wheels for Silicon Wafers

Honway Materials provide customized services,

Manufacturing the most suitable chamfering and grinding wheels for your silicon and sapphire wafers.

High-performance grinding wheels specifically designed for chamfering and grinding semiconductor material substrates, featuring a uniform and fine abrasive grain layer structure and manufactured using high-precision finishing technology.

After dressing, they exhibit a low defect rate, excellent quality, and superior machining accuracy.

The product line covers standard grinding wheels suitable for outer periphery and groove processing, and offers three grinding wheel styles: single-groove type, multi-groove type, and rough/fine mixed type, to meet various processing needs.

Product Features:

- Possess excellent shape retention, meeting the strict requirements for high precision and stability in silicon wafer chamfering.

- Adopt a metal bond design, effectively enhancing wear resistance and significantly extending service life, reducing replacement frequency.

- Maintain stable grinding performance even under long-term operation, ensuring consistent and stable machining quality.

- Single or multi-groove designs can be provided according to customer needs, and rough and fine grinding functions can be integrated into one wheel to meet different process conditions.

- Combining the advantages of long lifespan, low dressing frequency, and stable machining capability, helping to reduce overall processing costs.

Uses:

- Mostly metal bond grinding wheels and electroplated bond grinding wheels.

- Chamfering and grinding of silicon wafers and compound semiconductors.

- Compatible with the latest equipment from several representative wafer chamfering machine manufacturers, ensuring high compatibility and stable machining performance.

Application areas:

- Grinding wheels for chamfering and grinding semiconductor material substrates.

- Suitable for various types of processing such as V-shaped, R-shaped, single-groove, or continuous groove.

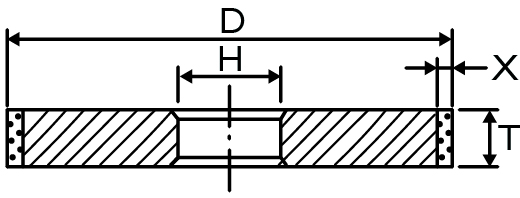

Please specify the following when ordering grinding wheels.

- The shape of the grinding wheel and the dimensions of each part: such as1A1、14A1

- Abrasive type: Diamond

- Grit: e.g:#150

- Concentration: e.g:C-75

- Bond type: For example, electroplated bond or metal bond

- Grinding wheel style: Single-groove type, multi-groove type, and rough/fine mixed type

- Use: For silicon wafers, sapphire wafers

- Quantity and delivery time:

- RPM and processing conditions:

- Processing equipment model:

- Most manufacturers label their grinding wheels with the following information:

| Abrasive Type | 150 Grit |

N Bonding degree |

75 Concentration |

R Bond |

3.0 Abrasive layer thickness |

|---|---|---|---|---|---|

| D: Natural Diamonds SD: Artifitial Diamonds |

#60 #80 #100 #150 #200 #270 #325 #400 #600 |

J / Soft L N P R / Hard |

25 50 75 100 125 150 |

M: Metal bond P: Electroplated |

1.0mm 1.5mm 2.0mm 3.0mm 5.0mm 10.0mm |

Sample pictures

Any questions? Contact HonWay