As technology advances, the application of various metals across industries has become increasingly diversified. Metallographic material science analysis (commonly known as metallography) has become crucial. Effective metallographic research can significantly enhance product quality and reduce process costs.

In this article, we’ll guide you through the complete metallographic research process and share some key points. Among them, grinding and polishing are vital steps in achieving good metallographic results!

Key Point 1: The familiar metallographic process includes “Cutting” > “Mounting” > “Grinding” > “Polishing” > “Etching” > “Verification,” representing a comprehensive workflow.

Key Point 2: Depending on research requirements, some processes may end after the polishing step.

Table of Contents

What’s Metallographic Analysis?

Metallographic research investigates the relationship between the microstructure and properties of metals and their alloys. By conducting microscopic analysis, metallography can reveal key features such as grain structure, phase composition, grain boundaries, and defects (e.g., voids, inclusions).

A “micro structure” refers to a homogeneous part of an alloy with uniform chemical composition, structure, and atomic arrangement, separated by distinct boundaries from others. The overall performance of an alloy is determined by the structural characteristics of its micro structures and their interactions. Alloy micro structures are mainly classified into two types: solid solutions and compounds. Solid solutions form when alloying element atoms dissolve into the base metal’s crystal lattice, while compounds consist of elements in fixed proportions forming a crystalline structure. Metallography studies these micro structures, providing insights into the material’s performance and processing history.

Metallographic Production Process

1. Sampling: A representative area of the material must be selected to ensure that the sample accurately reflects the material’s true characteristics. The sampling area should be free from uneven influences caused by processes like machining, heat treatment, or usage. The material is typically cut using methods such as mechanical cutting or wire cutting. Care must be taken to avoid overheating or applying excessive pressure during cutting to prevent the formation of heat-affected zones, which can cause grain deformation or structural changes.

2. Mounting: This step is crucial for securing and protecting the sample, especially for irregularly shaped or smaller samples. The sample is usually embedded in thermosetting or cold-setting resins, which provide stable support, facilitate grinding and polishing, and protect the edges from damage during processing. Mounting also makes it easier to handle the sample, ensuring stability during preparation and improving the accuracy and consistency of microscopic structure observations.

3.Grinding: Grinding is an important step in metallographic research. Its primary purpose is to flatten the sample’s surface by removing rough cutting marks and surface irregularities.

This process typically involves different grit sizes of abrasives, such as grinding pads or compound, to achieve the required surface smoothness.

This process involves starting with coarser abrasives and gradually progressing to finer ones until the sample surface shows only scratches in one direction.

During grinding, maintaining proper grinding pressure and uniform grinding time is essential to avoid overheating or deforming the sample surface.

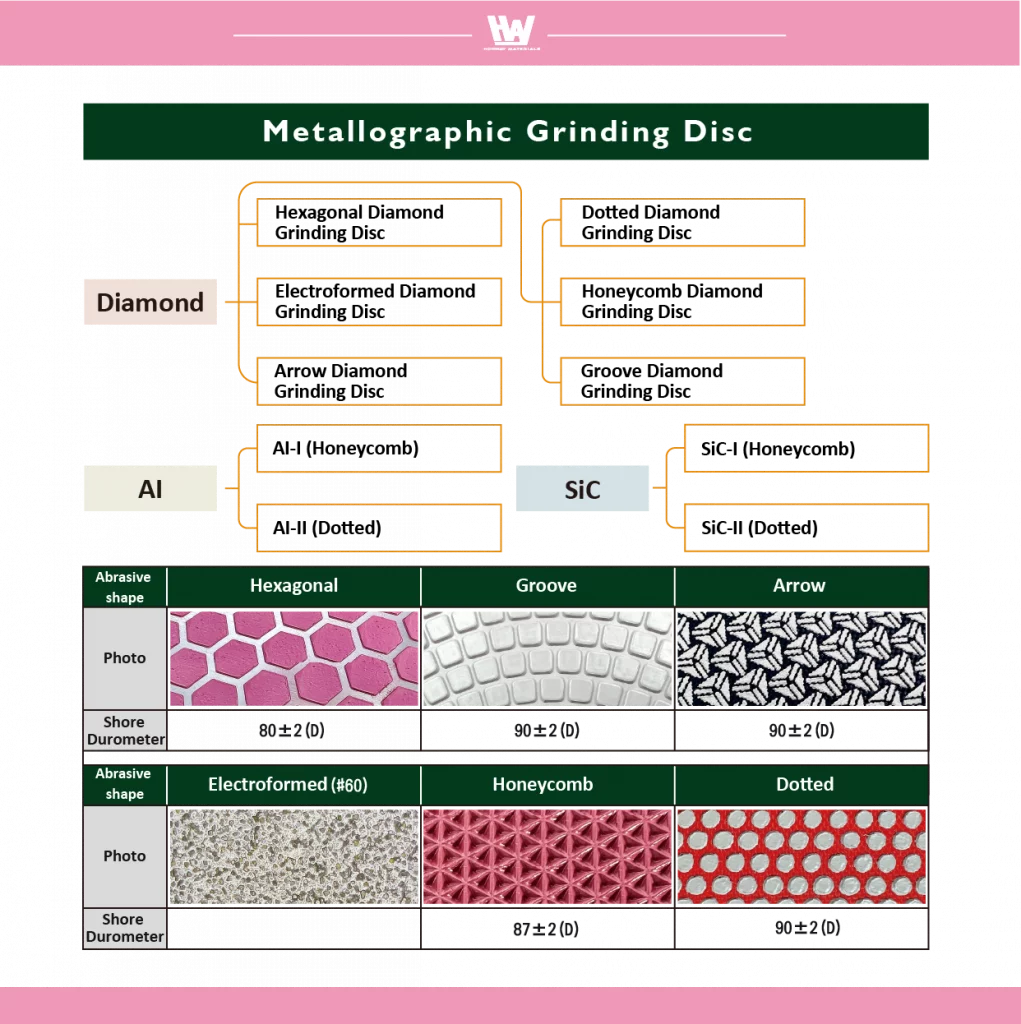

The patterns on grinding discs serve not only an aesthetic purpose but also functionally help to remove grinding debris and abrasive slurry. Along with the choice of abrasives, the pattern design influences the material removal rate. Different patterns cater to fast or slow grinding processes.

4. Polishing: Polishing is a crucial step in metallographic sample preparation. It aims to eliminate surface irregularities and grinding marks, resulting in a smooth, mirror-like finish.

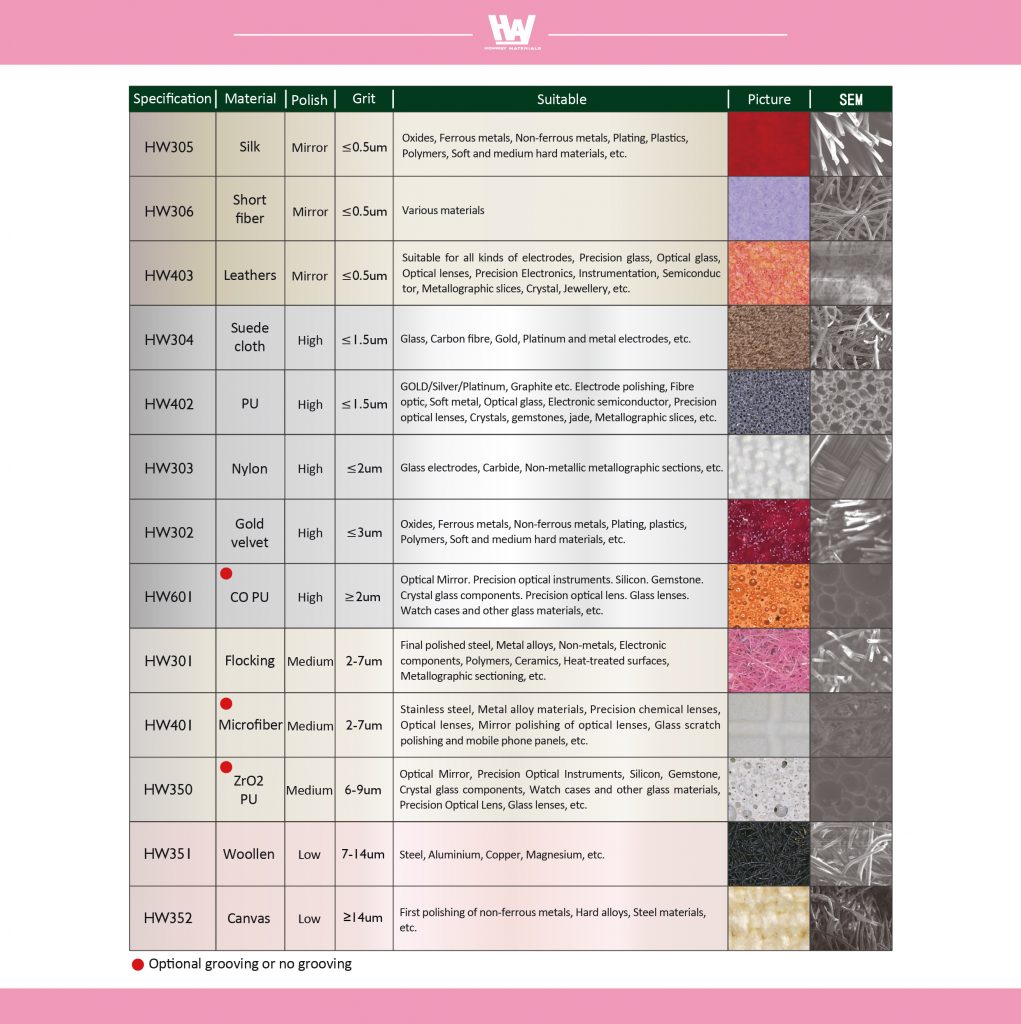

The process typically begins with rough polishing using felt pads or coarse canvas pads. Medium polishing often uses flocked pads or microfiber polishing pads, while fine polishing is performed using velvet pads or polyurethane pads. Finally, short fiber pads or silk pads are used for mirror polishing to achieve high gloss.

Tips: Selecting the appropriate polishing solution and pad is key to ensuring uniform abrasive distribution and polishing effectiveness. If scratches remain after polishing, consider returning to the previous step or testing a different abrasive formula.

5. Etching: After grinding and polishing, the sample is immersed in a specific etchant that selectively attacks different phases or grain boundaries, revealing the microstructure. Common etchants include acidic or alkaline solutions, and the choice depends on the sample’s composition and the desired structure to be revealed.

Controlling etching time is critical—too long or too short can impact observation results. A successful etching process will clearly reveal grain boundaries and micro structures distribution.

Caution: Not all samples require etching, as it may reveal unnecessary features that complicate the analysis. For example, etching cast iron with graphite may produce unwanted mottling, so the decision to etch should be made carefully based on the material characteristics.

Standards for Metallographic Samples

1. Representative Sample: The selected sample must represent the overall characteristics of the material. This ensures that the results of microscopic analysis reflect the general properties of the material, rather than just the localized features of a specific area.

2. Retention of All Structural Elements: During the preparation process, all micro structural elements (such as grains, phases, and inclusions) must be preserved. The preparation steps, including cutting, grinding, and polishing, should not alter the original shape or distribution of these elements.

3. Scratch-Free and Undeformed Surface: The sample must be prepared with a smooth, flawless surface. Any scratches from grinding or polishing, or plastic deformation due to heat treatment, should be avoided, as they can distort the observation of micro structures and lead to inaccurate results.

4. No Contaminants on the Sample Surface: The surface of the sample should be free from grease, dust, corrosion products, or other contaminants. These foreign materials can obscure or distort the micro structure, leading to misleading observations and inaccurate analysis.

5. Flat and Mirror-Like Surface: After polishing, the sample surface should be flat and mirror-like. This ensures that the micro structure can be clearly observed under a microscope without interference from surface roughness or unevenness.

Applications of Metallographic Research

1. Material Development: Metallographic research helps in developing metal alloys with enhanced performance by studying the microstructure of metal materials.

2. Failure Analysis: Through microscopic analysis of failed metal components, the causes of failure—such as fatigue, fracture, or corrosion—can be identified.

3. Quality Control: In industrial production, metallographic research is used to monitor the quality of metal products, ensuring that their microstructure meets design specifications.

Applications of Metallographic Analysis in Various Industries

Manufacturing: In metal processing and production, metallographic analysis is used to examine the structure, grain size, and phase distribution of metal materials. This ensures the strength and durability of the materials used in mechanical applications.

Automotive and Aerospace: Metallographic analysis inspects engine parts, gears, and other mechanical components to evaluate the effects of heat treatment, ensuring the reliability and durability of critical parts under high pressure and temperature. It also detects microcracks or defects in materials, helping prevent structural failures due to metal fatigue.

Medical Devices: This technique is applied to the examination of metals used in medical devices such as surgical tools and implants. Metallographic analysis ensures biocompatibility and durability, particularly for components implanted into the human body.

Electronics and Semiconductors: In electronics manufacturing, metallographic techniques are used to inspect the quality of solder joints and conductive materials, ensuring the stability of performance on a microscopic scale.

Construction and Civil Engineering: Metallographic analysis checks the quality of reinforcing steel used in reinforced concrete structures, ensuring stability and safety. It is also used to analyze the corrosion of metal components in bridges and buildings, assessing their lifespan and safety risks.

Recommended Polishing Tools

Nano diamond polishing solution / Grinding solution / Suspension >>>Polishiing solution

- Best suited for: mechanical operation

- State: liquid (oil-based/water-based/alcohol-based)

- Polishing can be performed using a double-sided grinding machine, chemical mechanical polishing (CMP), or metallographic grinding.

- ※ Since the abrasive is in a free state, it is suitable for large-scale polishing.

- ※ If the surface of the workpiece is still rough, choose a polishing liquid with larger particles.

Alumina / Cerium oxide polishing solution / Grinding solution / Suspension >>> Polishing solution

- Best suited for: mechanical operation

- Status: Liquid

- Scope of application: Generally used after diamond compound

- ※ Possesses the ability of repairing polishing marks on the workpiece.

- ※ Cerium oxide is recommended to be used with tools at low speed.

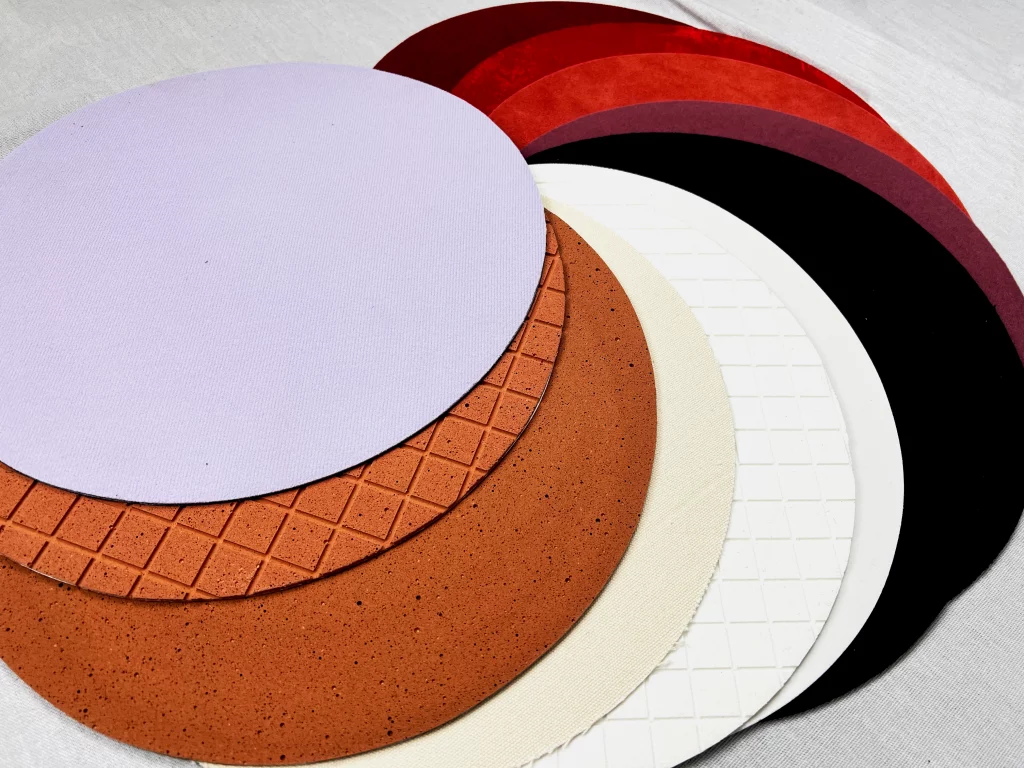

Polishing pad / Grinding pad >>>> Metallographic consumables

- Materials:

- Contains abrasive: Cerium oxide polishing pad, Diamond resin grinding disc, Electroplate diamond grinding disc

- Without abrasives: silk, leather, polyurethane (black velvet), woven fabric, fleece, porous, hard cloth, soft cloth, etc.

Article for Experiment

Polishing copper >>> Metal Polishing Materials-Introduction to Copper

Polishing Nickel >>> Metal Polishing Materials-Introduction to Nickel

Polishing Zinc >>> Metal Polishing Materials-Introduction to Zinc

Polishing Stainless Steel >>> Metal Polishing Materials-Introduction to Stainless Steel

Conclusion

Metallographic sample preparation is a critical process. Through proper sampling, mounting, grinding, polishing, and etching, understanding the standards for metallographic sampling allows for a clear presentation of the microstructure of metallic materials, which enables precise analysis and evaluation. Successful metallographic preparation effectively prevents sample deformation or contamination, ensuring an accurate reflection of the material’s properties.

Understanding metallographic research is essential for various industrial applications. It provides quantifiable data that can significantly contribute to the advancement of materials science, improving process efficiency and reducing production costs—an aspect that should never be overlooked.

We offer customized adjustments to the grinding process, tailored to meet processing requirements for maximum efficiency.

After reading the content, if you still don’t know how to select the most suitable option,

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have a subject that you want to know or a phone call that is not clear, you are welcome to send a private message to Facebook~~

Honway Facebook: https://www.facebook.com/honwaygroup