Recently, a research team from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy of Sciences has developed a groundbreaking aluminosilicate zeolite, ZMQ-1. This new material successfully overcomes the limitations of traditional zeolites in processing large molecules, such as pore size constraints, stability issues, and catalytic efficiency. The breakthrough represents a major advancement in catalytic processes within the petrochemical industry. The research findings were published in Nature, highlighting that ZMQ-1 is the first aluminosilicate zeolite with an intrinsically interconnected 28-ring mesoporous structure.

Table of Contents

Innovative Structure and Design of ZMQ-1

Zeolites are crystalline aluminosilicate minerals with microporous structures that can absorb or filter molecules, earning them the name “molecular sieves.” They have widespread applications in ion exchange, adsorption, and catalysis. In everyday life, zeolites are used as adsorbents and desiccants, catalysts or co-catalysts, detergents, and building materials. However, traditional zeolites have micropores smaller than 2 nanometers, which limits their ability to process larger molecules effectively.

In the past, researchers have attempted to introduce mesopores (2–50 nm) or macropores (>50 nm) into zeolites through post-treatment methods such as acid or alkali etching. This approach resulted in hierarchical or multiscale porous molecular sieves with a combination of micropores, mesopores, and macropores. However, these artificially introduced pores often lacked uniformity, leading to reduced crystallinity, compromised structural stability, and decreased acid strength, making them less suitable for industrial applications.

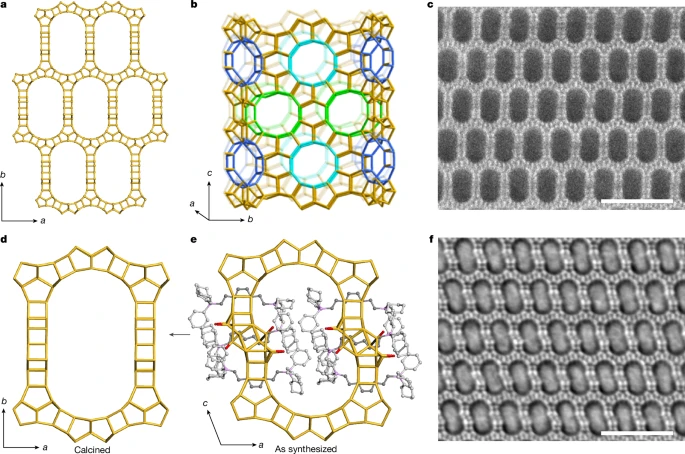

ZMQ-1 overcomes these challenges with its unique interwoven micro- and mesoporous channel system, composed of 28×10×10 membered rings. Its 28-ring mesopores measure 22.32×11.84 Å, placing them within the mesoporous range. The research team analyzed ZMQ-1’s structure using three-dimensional electron diffraction (3D ED) and scanning transmission electron microscopy (STEM). Their findings showed that the 28-ring mesopores are interconnected through 10-ring microporous windows, forming an efficient channel system. This structure allows both large and small molecules to diffuse smoothly, effectively eliminating the diffusion limitations faced by traditional zeolites.

Synthesis Strategy and Enhanced Stability

The successful synthesis of ZMQ-1 is attributed to the use of a phosphorus-based organic structure-directing agent (OSDA). Compared to conventional ammonium-based OSDAs, phosphorus-based OSDAs carry stronger positive charges and offer higher stability, promoting the formation of a stable mesoporous framework. Additionally, ZMQ-1 is crystallized through hydrothermal synthesis with an adjustable Si/Al ratio, allowing for customization in specific applications.

Professor Peng Lu stated: “ZMQ-1 is the first aluminosilicate zeolite with an intrinsic interwoven micro-mesoporous channel system. Unlike conventional mesoporous materials, which often suffer structural damage after template removal, the 28-ring interconnected channels of ZMQ-1 mark a significant breakthrough in zeolite design.”

Advantages of ZMQ-1 in Catalytic Applications

In heavy oil catalytic cracking, traditional zeolites struggle with large molecules due to their microporous constraints. In contrast, ZMQ-1 demonstrates superior catalytic performance. Compared to commercial zeolite catalysts, phosphorus-containing ZMQ-1 exhibits higher selectivity for light fuels (such as gasoline and diesel) in heavy oil catalytic cracking reactions. Additionally, it reduces the production of unwanted byproducts, such as coke, liquefied petroleum gas (LPG), and dry gas.

Furthermore, ZMQ-1 offers enhanced thermal and hydrothermal stability, ensuring that it maintains high performance even under harsh industrial conditions. Its unique mesoporous structure and stable chemical properties make it highly promising for applications in large-molecule catalytic conversion, adsorption-separation processes, and beyond.

Conclusion

As a novel aluminosilicate zeolite, ZMQ-1’s intrinsic interwoven micro-mesoporous channel structure effectively resolves the pore size limitations of traditional zeolites while exhibiting outstanding catalytic and stability properties. This breakthrough not only advances catalytic processes in the petrochemical industry but also creates new opportunities for heavy oil cracking and green energy conversion. Additionally, it opens new possibilities for the design and application of next-generation functional zeolite materials.

References:

- Breakthrough Zeolite Molecular Sieve Achieves More Efficient Heavy Oil Conversion into High-Value Fuels

- Breakthrough New Material Transforms Heavy Oil Into High-Value Fuels

- Peng Lu, Jiaoyan Xu, Yiqing Sun, Rémy Guillet-Nicolas, Tom Willhammar, Mohammad Fahda, Eddy Dib, Bo Wang, Zhengxing Qin, Hongyi Xu, Jung Cho, Zhaopeng Liu, Haijun Yu, Xiaobo Yang, Qiaolin Lang, Svetlana Mintova, Xiaodong Zou & Valentin Valtchev.(2024) A stable zeolite with atomically ordered and interconnected mesopore channel, Nature, 636, 368–373. DOI: 10.1038/s41586-024-08206-1

Source of the first image: Nature

We offer customized adjustments to the grinding process, tailored to meet processing requirements for maximum efficiency.

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have a subject that you want to know or a phone call that is not clear, you are welcome to send a private message to Facebook~~

Honway Facebook: https://www.facebook.com/honwaygroup

You may be interested in…

[wpb-random-posts]