Fuel Injection System

Fuel injection is used in all vehicles. The reason for the popularity of fuel injection is that it provides more precise control of the spray volume and atomization effect, and it has a very good performance in terms of fuel consumption and emission problems.

Fuel Injection System

Oil injection system grinding

Components such as hydraulic cams, nozzles, and nozzle housings are manufactured with high-precision superabrasive wheels.

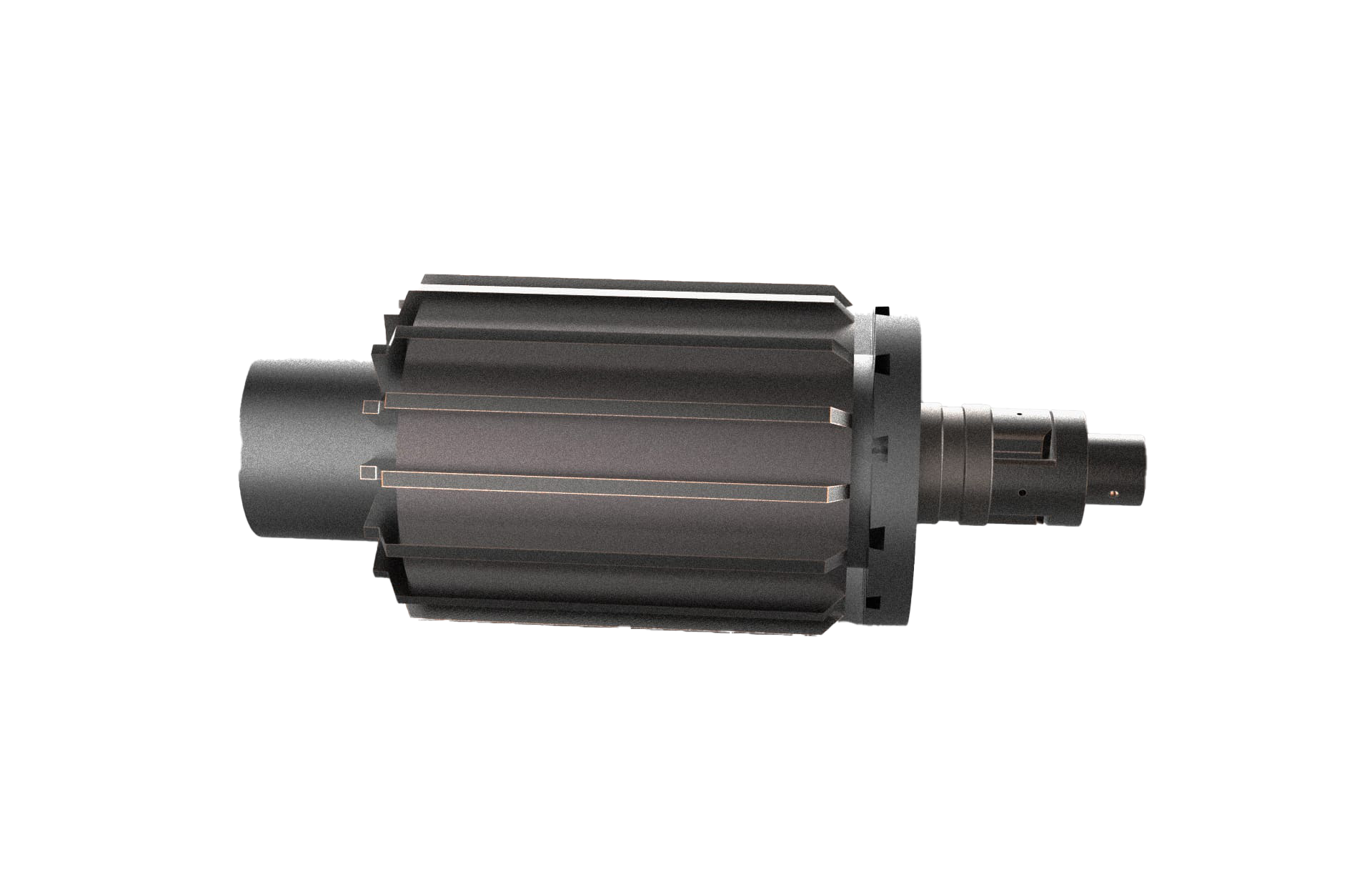

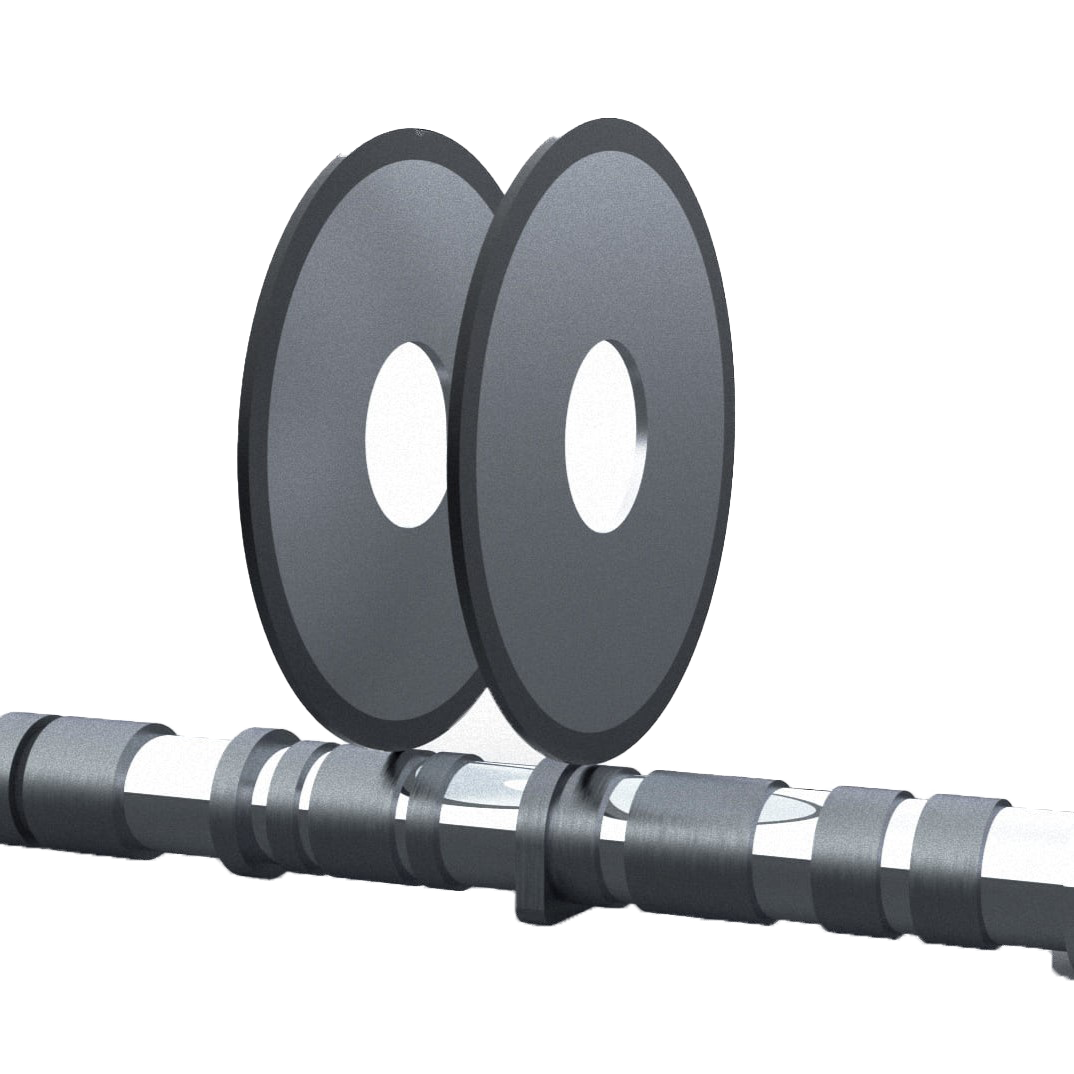

Camshaft

A camshaft is a component in a piston engine. Its function is to control the opening and closing of the valve. Although the camshaft speed in a four-stroke engine is only half of that of a crankshaft, the speed is still usually very high and the torque is very high, so the design of the camshaft requires a high level of strength and support. The material is usually special cast iron and occasionally forged. Since the valve motion law is related to the power and operating characteristics of the engine, camshaft design plays a very important role in the engine design process.

Camshaft

Camshaft grinding

Area to be sharpened

- Shaft head end

- Flange end

- Spindle diameter

- Shaft cover

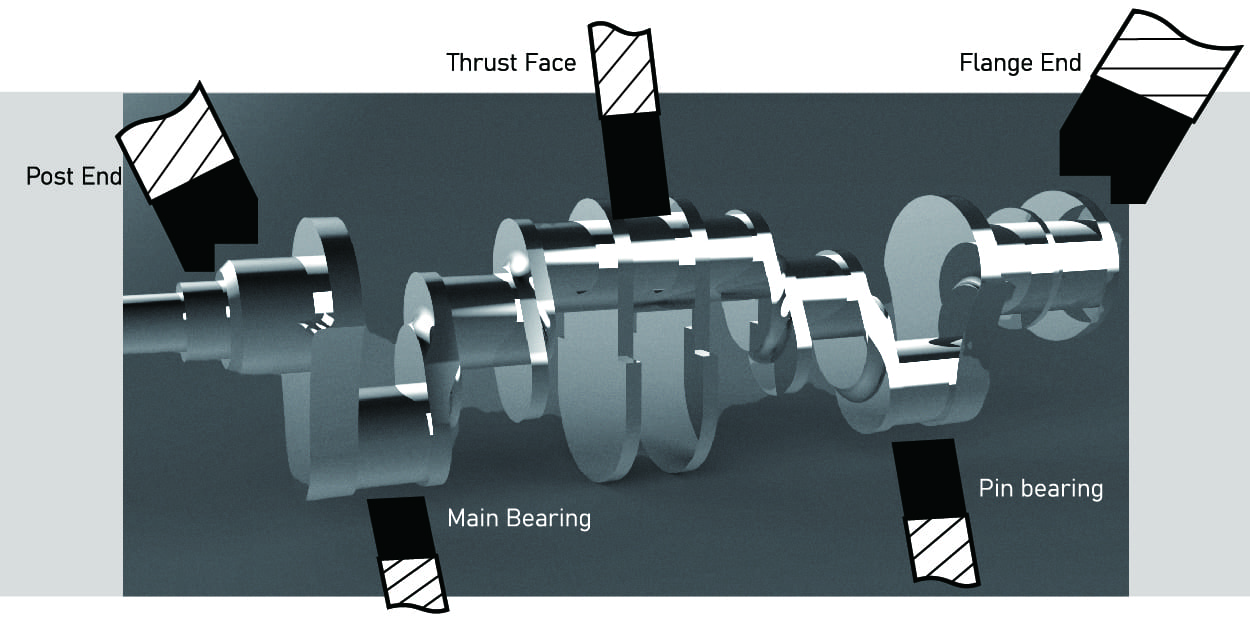

Crankshaft

The crankshaft is the part of a reciprocating piston engine that converts the kinetic energy of the piston’s linear reciprocating motion into rotational kinetic energy. A crankshaft consists of a long rotating shaft. In order to convert the reciprocating motion into rotary motion, the crankshaft is equipped with a “crankshaft arm” or crankshaft pin, which has a radial displacement between its center and the center of the crankshaft, and the larger end of the piston connecting rod will be connected to the crankshaft arm or crankshaft pin.

In a four-stroke cycle, a flywheel is usually added to the crankshaft to reduce the torque pulsation characteristics, and sometimes a rotary or vibration damper is added to the other end to minimize torsional vibration on the crankshaft.

Crankshaft

Crankshaft grinding

Area to be sharpened

- Shaft head end

- thrust surface

- Flange end

- Rod Neck

- Spindle neck

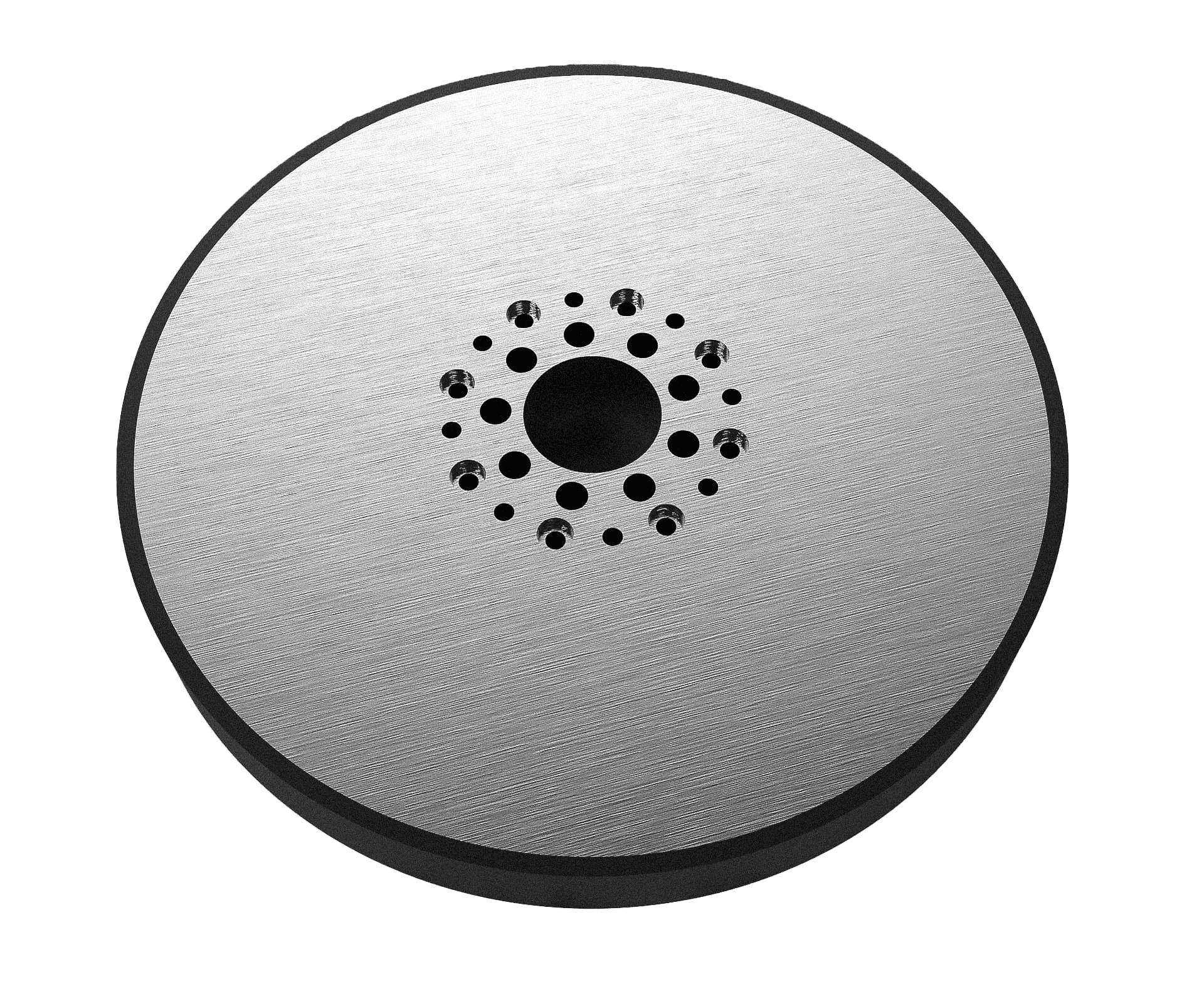

valve

The valve is used to control the opening and closing of the intake and exhaust holes above the engine combustion chamber. It must withstand high temperature, high pressure, severe knocking and must maintain good air tightness. The working environment is very harsh and it can be said to be the hardest working part of the entire car. The valve is driven by the crankshaft in the engine. A belt disk on the crankshaft is connected to another belt disk on the camshaft, and the crankshaft rotates to drive the camshaft, but sometimes instead of a belt, it is driven by a chain or directly by gears. The valve that closes the intake or exhaust port is pushed by the cam when the cam on the camshaft turns to the raised position, thereby opening the intake or exhaust port. When it turns to the blunt end, the valve is not pushed by the camshaft and is pushed back to its original position by the valve spring, closing the intake or exhaust port. This cycle repeats itself over and over again.

valve

Valve grinding

- Profile grinding of tapered surfaces

- Profile grinding of rods

- Double face grinding of seating rings

- Profile grinding of grooves

cylinder

A cylinder is a container in an internal combustion engine or an external combustion engine that allows the piston to reciprocate up and down. In a multi-cylinder engine, the cylinders are arranged in a row, which is called a cylinder bank. A V-type engine is composed of two groups of cylinder banks in a V shape. Multiple or one cylinder bank constitutes the cylinder body.

cylinder

Cylinder bore honing

High precision honing is utilized to ensure the dimensional accuracy and surface quality of the cylinder bore and cylinder liner of the cylinder block and cylinder head.