Are your precision components suffering from reduced performance and shortened lifespan due to overheating in the era of high-power electronics and high-speed communication? Effective thermal management has become the top priority for enhancing product competitiveness and reliability.

Diamond, traditionally synonymous with luxury, is now disrupting the thermal management bottleneck in the industrial and technology sectors due to its exceptionally superior thermal conductivity.

Unlike metals that conduct heat through free electrons, diamond utilizes its unique phonon lattice vibrations, combined with tightly packed atomic arrangements, strong covalent bonds, and extremely low lattice defects, to achieve thermal conductivity far exceeding that of metallic materials. This makes it a crucial core element leading the way in future high-efficiency thermal management technology.

This article will delve into why diamond possesses excellent thermal conductivity, the differences in its thermal and electrical conduction mechanisms, and the current development status and market potential in various high-end applications.

Table of Contents

Diamond Introduction

- Chemical composition: Natural diamond is a crystalline state of carbon, which is an allotrope of carbon with graphite, and the main impurity is N (0.01~0.25%).

- Color: Pure diamond is transparent and colorless, but can display different colors due to various impurities and crystal defects. Natural diamonds are mostly light yellow, while synthetic diamonds are yellow-green.

- Physical properties: high melting point, high thermal conductivity, high resistivity, density ρ= 3.51524g/cm3.

- Chemical properties: hydrophobic, lipophilic, inert at room temperature, and resistant to chemical reagents except for certain oxidizers when heated to 1000℃.

- Oxidation: When the temperature of diamond is above 600℃ in pure oxygen, the diamond begins to lose its luster and the black surface turns to ashes. It starts burning at 700~800℃.

- The temperature at which F0 synthetic diamonds begin to oxidize in the air is 740~840℃, and the ignition temperature is 850~1000℃.

※Further reading: Introduction to Abrasives – Diamonds

Why Does Diamond Have Good Thermal Conductivity?

Diamond’s thermal conductivity primarily stems from the vibrational propagation of phonons. Unlike general metals that rely on free electrons for heat transfer, diamond, as an insulator, primarily transfers thermal energy through phonons—the quantum units of lattice vibrations. Diamond possesses extremely high crystal integrity and very few defects. Coupled with the light mass of carbon atoms and strong carbon-carbon covalent bonds, phonons have a long mean free path and low scattering, thus achieving extremely high thermal conductivity. Natural Type IIa diamonds can have a thermal conductivity of 2200~2600 W/m·K, far exceeding most metallic materials.

Thermal Conduction Mechanism Explanation:

- Heat conduction in metals: Primarily transfers thermal energy through free electrons.

- Heat conduction in diamonds:

- Phonons can be regarded as quantum units of lattice vibrations. When a portion of atoms are stimulated by thermal energy and begin to vibrate, this vibration propagates like water waves along the crystal structure.

- In materials like diamond, where atomic arrangements are extremely dense and highly symmetrical, phonons can propagate at high speeds with low resistance. Therefore, thermal energy can rapidly diffuse from one point throughout the entire material.

Reasons for High Phonon Thermal Conduction Efficiency:

- Small carbon atom mass → Fast phonon propagation speed.

- Strong carbon-carbon bonds → High phonon energy, short wavelength.

- Few crystal defects → Low phonon scattering, long mean free path.

- Simple structure → Conducive to stable propagation of high-frequency phonons.

Thermal Conduction Effect of Single Crystal vs. Polycrystal

| Item | Monocrystalline Diamond | Polycrystalline Diamond |

| Thermal conductivity | Can exceed 2000–2200 W/m·K | About 1200 W/m·K |

| Structural characteristics | No grain boundaries, less phonon scattering, higher hardness | There are grain boundaries and many phonon scattering |

| Thermal efficiency | Very high, suitable for high power components | Good, can be used for heat dissipation of LEDs |

| Application potential | High-end power components, GaN chips | LED, laser and other mid-to-high-end applications |

Advantages of Single Crystal and Polycrystalline Diamond Films:

- Regardless of whether it’s single crystal or polycrystalline, their thermal conductivity far exceeds traditional materials like silver, copper, and aluminum.

- Honway Single Crystal Advantages: Its nearly perfect crystal structure exhibits superior thermal conduction efficiency compared to polycrystalline, making it an ideal choice for high-end applications such as GaN chips.

- Honway Polycrystal Advantages: It offers large area and excellent cost-effectiveness, making it a preferred solution for thermal management in mid-to-high-end industrial applications such as LEDs and lasers.

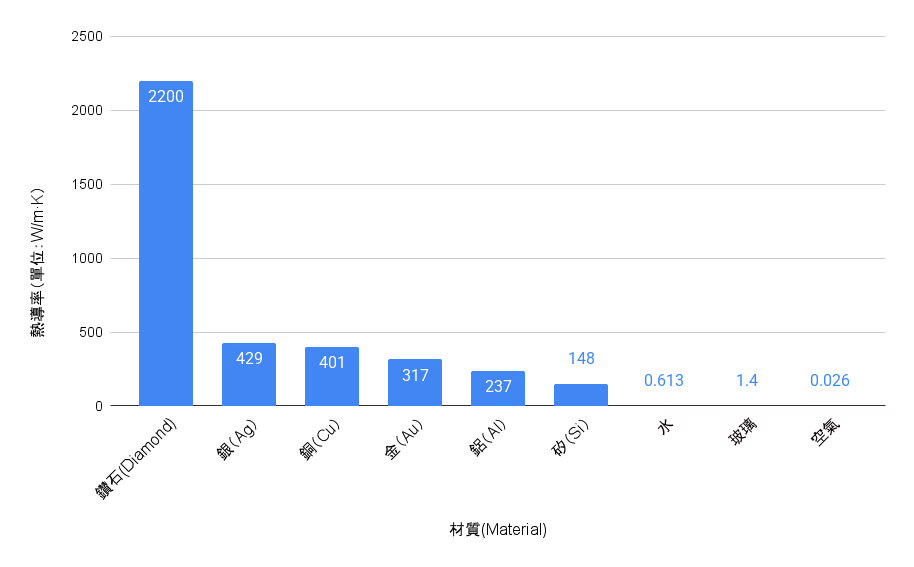

Comparison of Common Thermal Conductive Materials on the Market

| Material | Thermal conductivity (unit: W/m·K) |

| Diamond | 2200–2600 |

| Ag | 429 |

| Cu | 401 |

| Au | 317 |

| Al | 237 |

| Si | 148 |

| Transparency | 0.613 |

| glass | 1.4 |

| Air | 0.026 |

In the past, when buying diamonds, some people would lick them with the tip of their tongue. If the tip of their tongue felt cool, it was a real diamond; if it felt warm, it was just glass. This process is actually using the tip of the tongue as a probe to conduct a thermal conductivity comparison experiment on the gemstone. Because the thermal conductivity of glass is very small, and the heat transfer rate of a real diamond is more than a thousand times higher than that of glass, a sensitive tongue can indeed easily distinguish the difference between the two.

Why Choose Diamond as Your Preferred Thermal Management Solution?

Did you know?

When the chip surface temperature reaches 70-80°C, for every 1°C increase in temperature, the chip’s reliability decreases by 10%. Even more concerning, over 55% of equipment failures are directly related to overheating!

Facing these severe challenges, you need the most reliable thermal management solution. Diamond is currently the material with the highest known thermal conductivity, with a thermal efficiency that is:

- 13 times that of Silicon (Si)

- 4 times that of Silicon Carbide (SiC)

- 4-5 times that of Copper and Silver

Choosing diamond means choosing to provide unparalleled thermal management capabilities for your critical components, ensuring stable product operation and significantly extending service life.

Does “Good Thermal Conductivity” Equal “Good Electrical Conductivity”?

In high-performance electronic design, a common misconception is: “Does a material with good thermal conductivity always have good electrical conductivity?” The answer for diamond is: No.

Heat and Electrical Conduction Mechanisms:

| Conduction type | Conduction method |

| Thermal conductivity | Transfer of heat energy through phonons (atomic vibrations) |

| Electrical Conduction | There are almost no free electrons for the current to move |

Although diamond is extremely efficient in atomic vibrations (phonons), resulting in excellent thermal conductivity (exceeding 2000 W/m·K), it is an excellent electrical insulator (with extremely low electrical conductivity) because its valence electrons are all involved in covalent bonds, leaving almost no free-moving electrons.

Application areas

Leveraging its unparalleled thermal conductivity and electrical insulation properties, diamond has become a key material for solving thermal management challenges in high-power density equipment, demonstrating its enormous potential in the following fields:

1. High-Power Electronic Components

- GaN power chips, Field-Effect Transistors (FETs), power amplifiers.

- Single-crystal diamond substrates can effectively improve heat dissipation and component stability, significantly extending component lifespan, enhancing system stability, and enabling higher operating frequencies.

2. LED and Laser Thermal Management

- Polycrystalline diamond films bonded to LED chips → effectively suppress hot spots, improve brightness and lifespan, ensure stable light source output, reduce light decay, and enhance product reliability.

3. Optoelectronic and Infrared Components

- Diamond’s high light transparency and high refractive index → suitable for use as laser windows, missile radomes, infrared sensors, and solar cell efficiency enhancement layers, offering excellent optical stability and maintaining performance in harsh environments.

4. Integrated Circuit (IC) Substrates:

- Silicon’s thermal conductivity is only about 1/15 of diamond’s. If diamond can replace silicon as a substrate, it can significantly improve the thermal management bottleneck, break through traditional thermal management limitations, and enable more miniaturized and high-performance chip designs.

5. Thermally Conductive Insulating Materials

- Utilizing its high thermal conductivity but electrical insulation properties, it is used in scenarios with special thermal management requirements, providing safe and reliable thermal management solutions in high-pressure or high-frequency environments.

Current Market Scale

| Application areas | Market size in 2025 (US$) | Forecasted Compound Annual Growth Rate (CAGR) | Main application industries |

| CVD diamond heat dissipation substrate (Submount) | 13.6 billion | 11.7%(2024–2031) | High-power semiconductors, lasers, communication modules, etc. |

| Heat Spreaders | 180 million | 9.86%(2025–2033) | Aerospace, Defense, Telecommunications, Advanced Electronics |

| Heat Sinks | 240 million | 4.2%(2025–2033) | High power electronics and optical modules |

| Cu-Diamond | 338 million | 12.1%(2025–2033) | High-performance computing, 5G, electric vehicles, aerospace |

| Monocrystal | 1.637 billion | 4.7%(2025–2033) | Precision tools, semiconductors, optical components |

Market Growth Drivers:

- High-Power Density Electronic Devices: With the development of semiconductors, 5G, electric vehicles (EVs), AI servers, and other technologies, the demand for efficient thermal management materials is increasing.

- CVD Technology Advancement: The maturity of Chemical Vapor Deposition (CVD) technology has made mass production of high-quality diamond materials possible, reducing costs and expanding the scope of applications.

- Aerospace and Defense Applications: The stability of diamond materials in extreme environments is leading to their increasing use in the aerospace and defense sectors.

Industrial Applications and Prospects:

Diamond’s high thermal conductivity and electrical insulation make it widely applicable in semiconductors, high-power electronics, laser modules, 5G communication equipment, electric vehicle power modules, and other fields. In the future, as the demand for efficient thermal management solutions increases, the diamond thermal conductive material market is expected to continue to grow.

Conclusion

Diamond, with its unique atomic structure and excellent phonon conduction mechanism, demonstrates irreplaceable thermal management advantages in high-power, high-heat density applications. Despite being an excellent electrical insulator, its thermal conductivity is several times that of traditional metals, with single-crystal diamond being able to meet the most stringent thermal dissipation requirements.

From LEDs, lasers, and GaN chips to cutting-edge applications like 5G communication and electric vehicles, diamond is increasingly becoming a core component in advanced thermal management systems. With the maturity of CVD technology and the continuous expansion of market demand, Honway’s diamond thermal conductive materials not only represent leading industrial value and vast market potential but will also be your key partner in driving the development of new-generation electronic and communication technologies and achieving breakthroughs in product performance. Contact us now, and let us provide tailor-made diamond solutions for your thermal management challenges!

Action

- Free inquiry and evaluation

- Customized diamond cooling solution design

- Implementation and performance verification

- >>> Welcome to contact us

We offer customized adjustments to the grinding process, tailored to meet processing requirements for maximum efficiency.

After reading the content, if you still don’t know how to select the most suitable option,

Feel free to contact us and we will have specialist available to answer your questions.

If you need customized quotations, you’re also welcome to contact us.

Customer Service Hours: Monday to Friday 09:00~18:00 (GMT+8)

Phone: +8867 223 1058

If you have a subject that you want to know or a phone call that is not clear, you are welcome to send a private message to Facebook~~

Honway Facebook: https://www.facebook.com/honwaygroup

You may be interested in…

[wpb-random-posts]