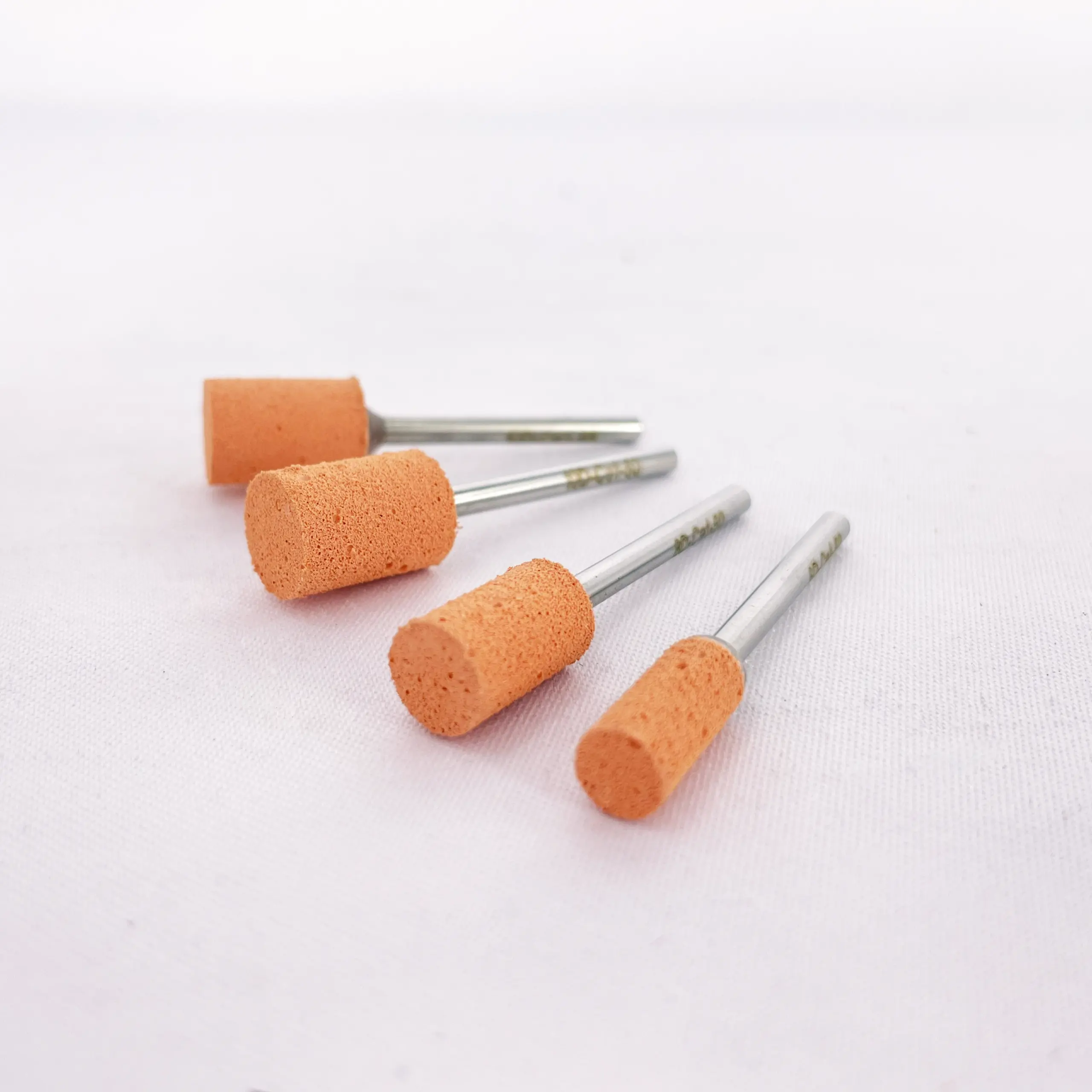

Cerium oxide polishing leather

Cerium oxide polishing leather is a rubber abrasive synthesized from high-quality cerium oxide and a rubber adhesive.

It can achieve ideal finishes by pairing different polishing liquids with various polishing workpieces.

Features of Cerium Oxide Polishing Leather

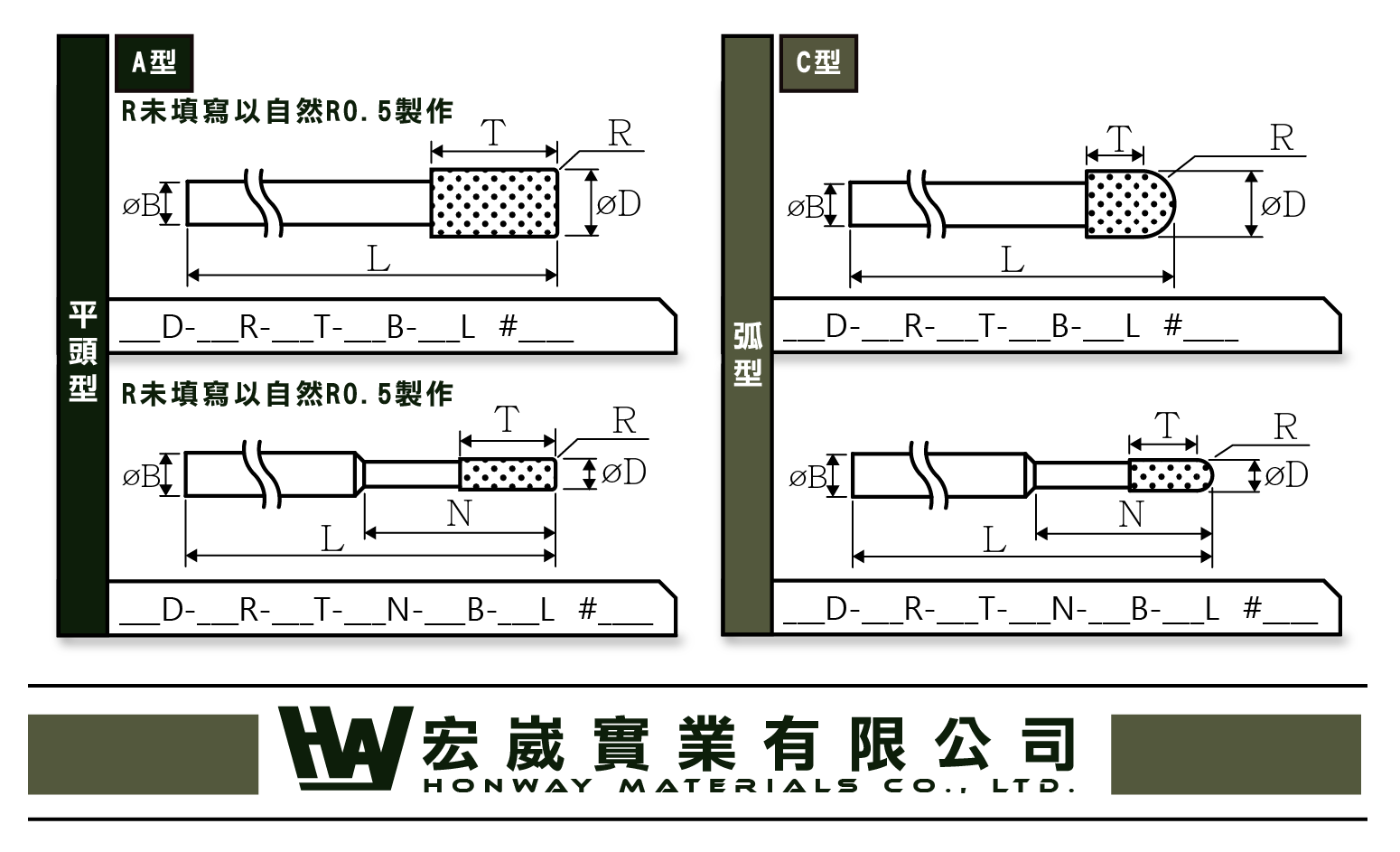

- Customizable applications such as wheel/rod/metallographic polishing pads according to requirements

- Adjustable thickness/hardness/grit size according to requirements

- Grooving possible

Application Range and Matching Polishing Liquids

| Application Range and Matching Polishing Liquids | |||

|

glass |

crystal |

ceramics |

Metal |

|

+ Cerium Oxide Polishing Liquid |

+ Silicon Dioxide Polishing Liquid |

+ Silicon Dioxide Polishing Liquid |

+ Aluminum Oxide Polishing Liquid |

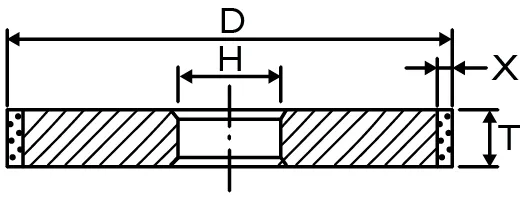

Cerium Oxide Polishing Wheel Sample Drawing

※ This model doesn’t include core

Grit size: Maximum 3um

Hardness: 40-90 degrees

Cerium Oxide Polishing Rod Sample

Grit size: Maximum 3um

Hardness: 40-90 degrees

Please note

The elasticity of rubber is significantly different from that of ordinary grinding wheels. Its deformation during polishing is extremely large, and it will be dangerous if used like ordinary abrasives or cutting tools.

Please strictly observe the maximum operating rotational speed limit and ensure correct installation on grinders or other equipment.

Before starting work, please check if the polishing leather has fine lines, cracks, or damage. When testing the installation on equipment, for your safety, rotate at a low speed to confirm if there is wobbling or other abnormalities.

Due to the elasticity of rubber, do not increase the load rapidly.

Sparks may be generated in the dust. Please use protective measures such as barrier plates and dust prevention devices, and ensure sufficient ventilation.

During use, please wear dust masks, protective glasses, protective gloves (wear gloves as appropriate for the tool), and safety shoes.

Product Storage: Please avoid direct sunlight, ultraviolet rays, radiation, ozone, and high temperature and humidity environments. Store in a cool, dark indoor place with good ventilation.

Please note that the product color may differ from the appearance of the above pictures depending on the process, manufacturing steps, and grit size. The actual delivered product shall prevail.